Device for reducing locking resistance of door leaf of civil defense door

A technology for civil air defense doors and door leaves, which is applied in sealing devices, building locks, buildings, etc. It can solve the problems of increased operating resistance of the locking mechanism, which is not conducive to the locking and sealing of the door leaf and the door frame, so as to reduce the operating force and labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

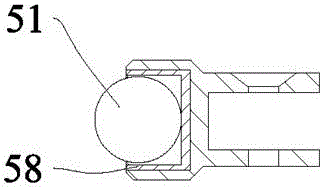

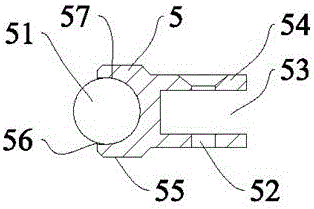

[0029] See attached figure 1 And attached figure 2 , the first card holder 5 is a rectangular support, with a strip-shaped head 55 and a strip-shaped tail 54, the end surface of the strip-shaped head 55 is provided with a spherical groove 57, the spherical groove The steel ball 51 is movably embedded in the 57, and the end surface of the elongated tail 54 is provided with a slot 53 along the length direction, and the slot 53 is provided with two sets of screw holes 52 that pass through. The locking slot 53 is inserted into a part of the locking side of the locking slot 41 by a sleeve. Three steel balls 51 of the same specification are arranged on the end face of the elongated head 55 along the length direction. The opening of the spherical groove 57 is provided with a card edge 56 to prevent the steel ball 51 from slipping off. The card edge 56 can be formed by tapping the opening edge of the groove 57 after the steel ball 51 is loaded to make the opening deform and shrink....

Embodiment 2

[0035] See attached Image 6 And attached Figure 7 , the second deck 7 is basically the same as the first deck 5, and is also a rectangular support with a strip-shaped head 73 and a strip-shaped tail 74, and the middle of the strip-shaped head 73 Roller grooves 75 are provided in the transverse direction, and lugs 76 are formed at both ends. The lugs 76 are provided with pin holes penetrating through them. Also, a slot 53 is provided on the end face of the elongated tail 74 along the length direction. The slot 53 is provided with Two sets of screw holes 52 pass through oppositely, and the locking groove 53 is sleeved on a part of the locking edge of the locking groove 41 .

[0036] The roller 71 is placed in the roller groove 75 and connected with the ear plate 76 with holes through the pin shaft 72, wherein the roller 71 rotates on the pin shaft 72, and the pin shaft holes of the pin shaft 72 and the ear plate 76 do not rotate mutually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com