screw

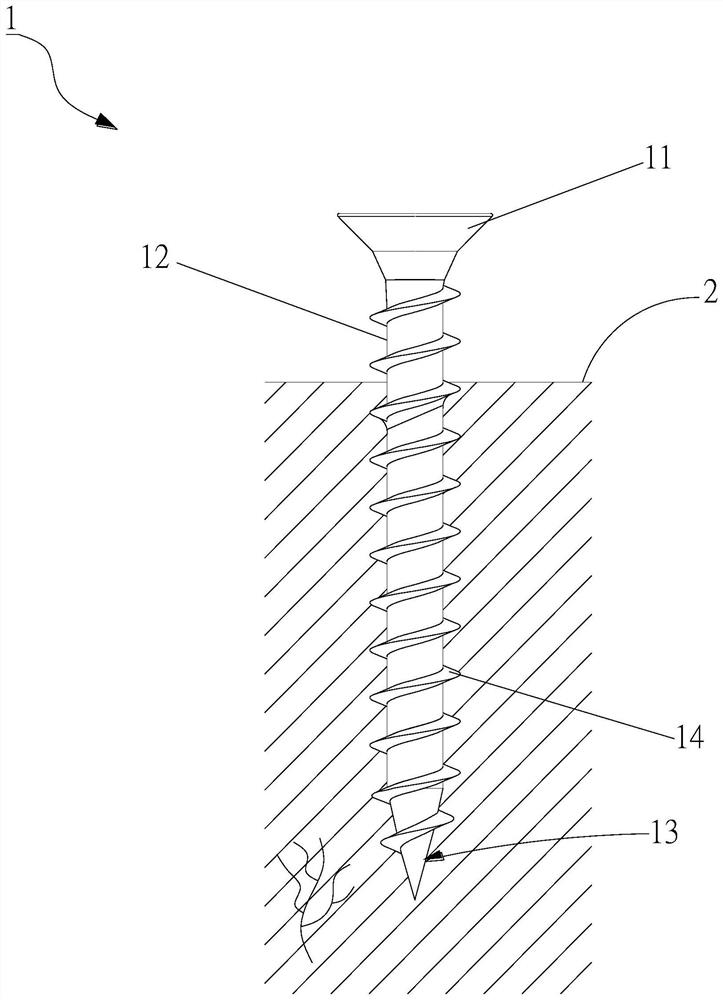

A screw and thread technology, applied in the field of screws that accelerate the improvement of locking efficiency, can solve the problems of increased locking torque, compression, affecting the locking efficiency, etc., and achieve the effect of reducing locking resistance and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The foregoing and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of preferred embodiments with reference to the drawings.

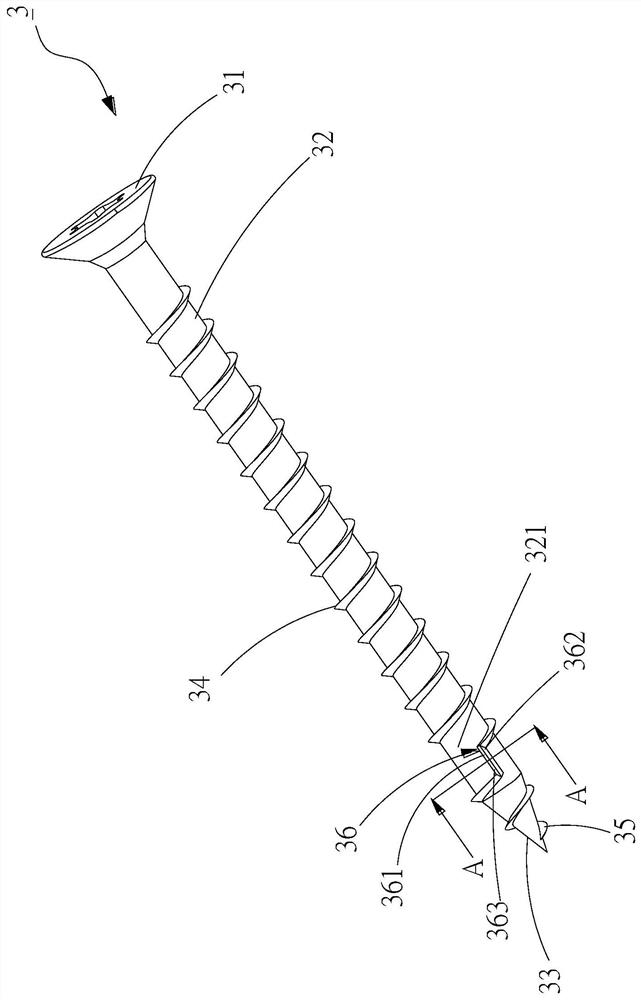

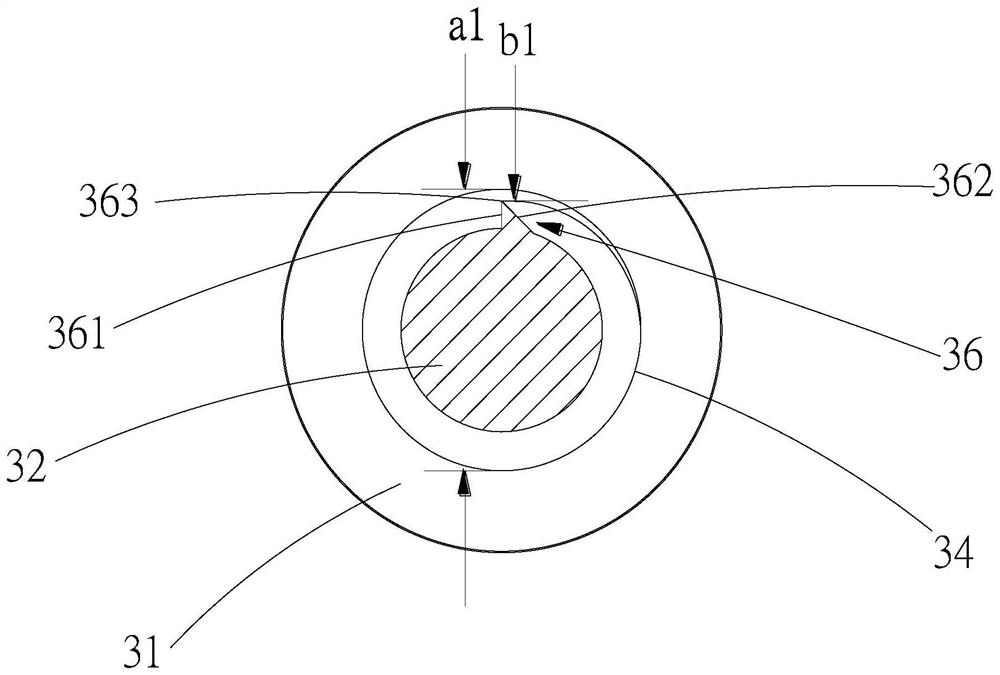

[0054] refer to figure 2 , the first preferred embodiment of the present invention, the screw 3 includes a screw head 31, a rod body 32 extending outwards from the screw head 31, a lock opposite to the screw head 31 and formed at the other end of the rod body 32 part 33, a helical ring set on the rod body 32 and a first thread 34 extending from the screw head 31 to the lock part 33, and a screw ring set on the rod body 32 near the lock part 33 and toward The guide tooth 35 extending in the direction of the screw head 31, and one end of the aforementioned first thread 34 and the corresponding end of the guide tooth 35 are not in contact with each other, so that the first thread 34 and the guide tooth 35 are not in contact with each other. A toothless section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com