Three-color injecting molding device with adjustable middle injecting nozzle

An adjustable, nozzle technology, applied in the field of injection molding devices, can solve the problems of single adaptability, inflexible use, inability to adapt to molds, etc., and achieves the effect of strong sealing effect, easy locking operation, and increasing sealing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

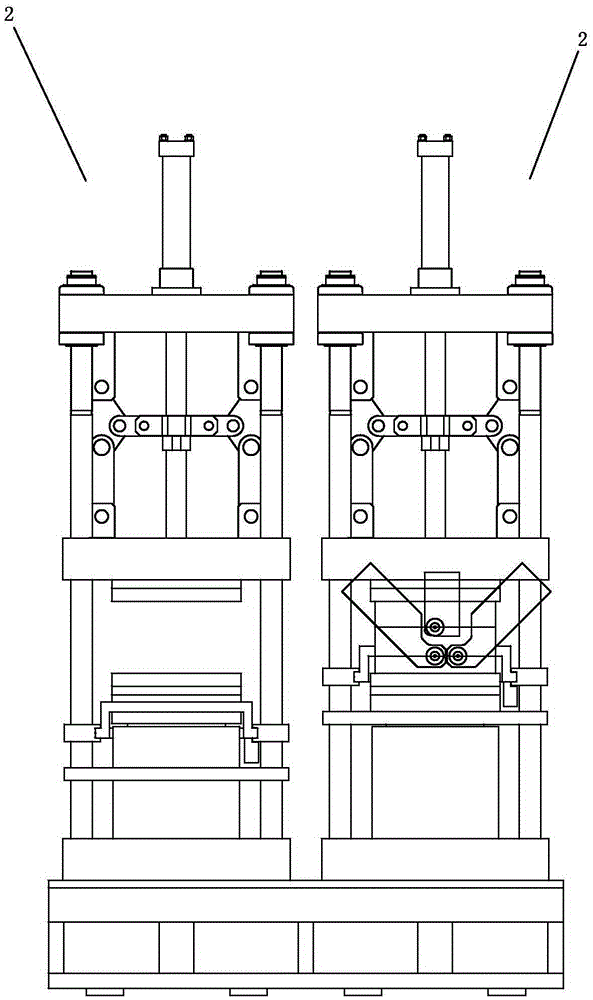

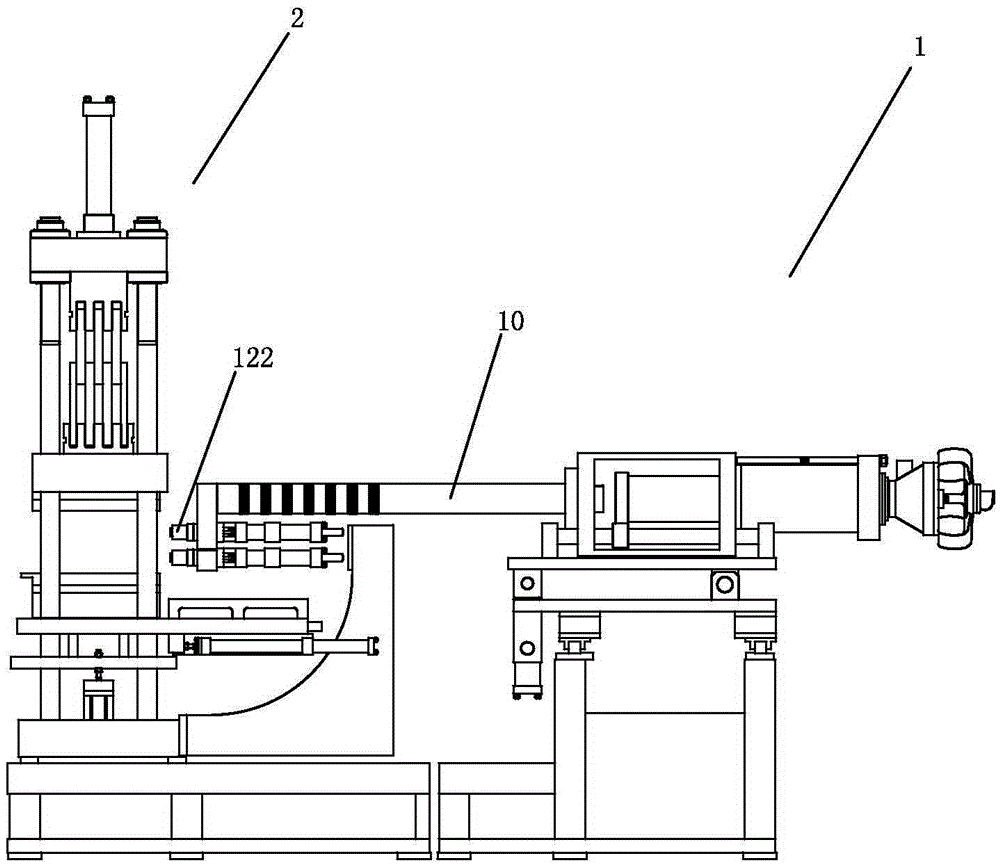

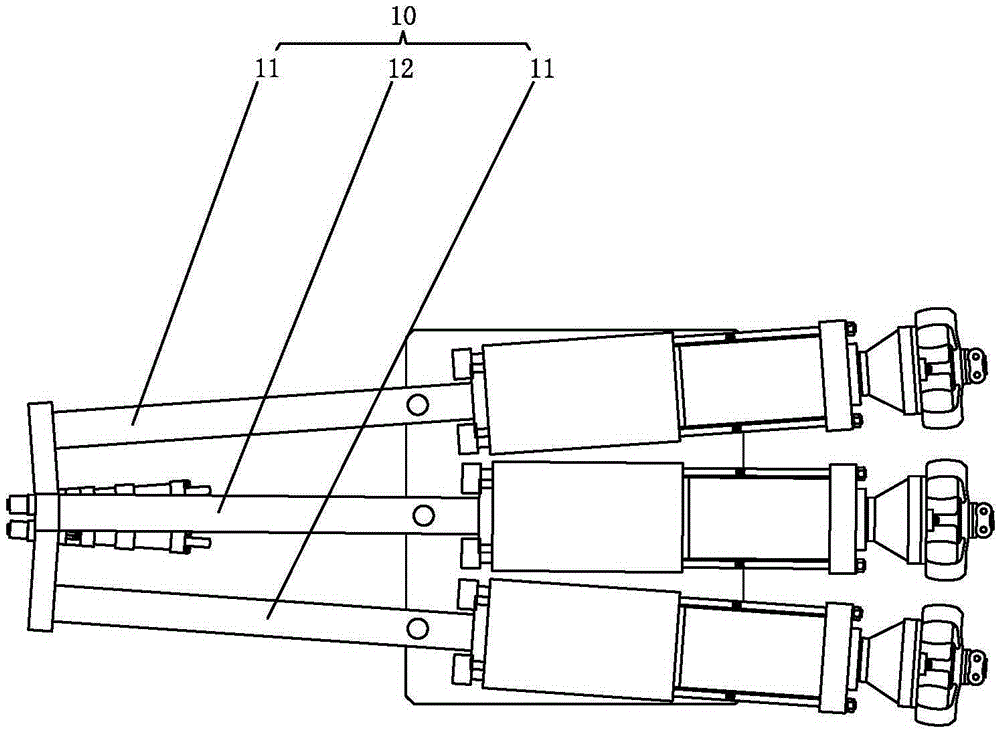

[0044] A three-color injection molding device with an adjustable middle injection nozzle of the present invention, such as Figure 1-5 As shown, it includes injection mechanism 1 and molding mechanism 2.

[0045] Injection mechanism 1 comprises three injection guns 10, being respectively two side injection guns 11 on both sides and an intermediate injection gun 12 between the two sides injection guns 11; The main body of the gun, the side injection nozzle located at the discharge end of the side injection gun main body, and the side transfer elbow connected between the side injection gun main body and the side injection nozzle; the middle injection gun 12 includes the middle injection material The gun main body 121, the middle injection nozzle 122 located at the discharge end of the middle injection gun main body 121, and the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com