Double-layer holographic anti-counterfeiting transfer paper and production method thereof

A holographic anti-counterfeiting and transfer paper technology is applied in the field of double-layer holographic anti-counterfeiting transfer paper and its preparation, which can solve the problems of increasing process flow, poor adhesion, and increasing production costs, and achieves clear anti-counterfeiting information, strong sense of hierarchy, and product quality. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

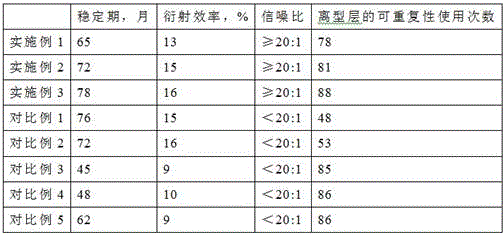

Embodiment 1

[0031] A preparation method of double-layer holographic anti-counterfeiting transfer paper, comprising the following steps:

[0032] In step (1), corona treatment is performed on the BOPP film, and then a release layer coating is applied to form a release layer with a coating thickness of 0.8-1 μm. After coating at room temperature, drying is performed at 40° C.;

[0033] The preparation method of the release coating is as follows: first, the following raw materials are prepared in parts by weight: 30 parts of hydrogen-containing silicone oil, 0.5 parts of carnauba wax, 10 parts of polytrifluoropropyl methyl siloxane, nanometer 1 part of tourmaline, 0.1 part of nano zinc oxide, 0.5 part of dicyclohexyl peroxydicarbonate, 28 parts of carboxylic acid type water-based polyurethane, 1 part of maleic anhydride, 0.1 part of hexamethyldisilazane; Silicone oil, polytrifluoropropylmethylsiloxane, nano-tourmaline, nano-zinc oxide and hexamethyldisilazane are stirred until they are evenl...

Embodiment 2

[0046] A preparation method of double-layer holographic anti-counterfeiting transfer paper, comprising the steps of:

[0047] Step (1), corona treatment is performed on the BOPP film, and then the release layer coating is applied to form a release layer with a coating thickness of 0.8-1 μm. After coating at room temperature, dry at 50°C;

[0048] The preparation method of the release layer coating is as follows. First, the following raw materials are prepared in parts by weight: 35 parts of hydrogen-containing silicone oil, 2 parts of carnauba wax, 18 parts of polytrifluoropropylmethylsiloxane, nano 2 parts of tourmaline, 0.2 part of nano zinc oxide, 2 parts of dicyclohexyl peroxydicarbonate, 37 parts of carboxylic acid type water-based polyurethane, 2 parts of maleic anhydride, 0.2 part of hexamethyldisilazane; Stir silicone oil, polytrifluoropropylmethylsiloxane, nano-tourmaline, nano-zinc oxide and hexamethyldisilazane until evenly mixed, then raise the temperature to 55°C,...

Embodiment 3

[0061] A preparation method of double-layer holographic anti-counterfeiting transfer paper, comprising the steps of:

[0062] Step (1), corona treatment is performed on the BOPP film, and then the release layer coating is applied to form a release layer with a coating thickness of 0.8-1 μm. After coating at room temperature, dry at 45°C;

[0063] The preparation method of the release layer coating is as follows. First, the following raw materials are prepared in parts by weight: 32 parts of hydrogen-containing silicone oil, 1 part of carnauba wax, 13 parts of polytrifluoropropylmethylsiloxane, nano 1.2 parts of tourmaline, 0.15 parts of nano zinc oxide, 1 part of dicyclohexyl peroxydicarbonate, 32 parts of carboxylic acid type water-based polyurethane, 1.6 parts of maleic anhydride, 0.18 part of hexamethyldisilazane; Stir silicone oil, polytrifluoropropylmethylsiloxane, nano-tourmaline, nano-zinc oxide and hexamethyldisilazane until evenly mixed, then raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com