A papermaking method for in-machine coating of base paper for water transfer printing paper bottom paper

A technology of water transfer paper and coating, which is applied in papermaking, paper machine, textile and papermaking, etc. It can solve the problems of low output and slow stripping time, achieve high smoothness and surface performance, improve performance, and stripping fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

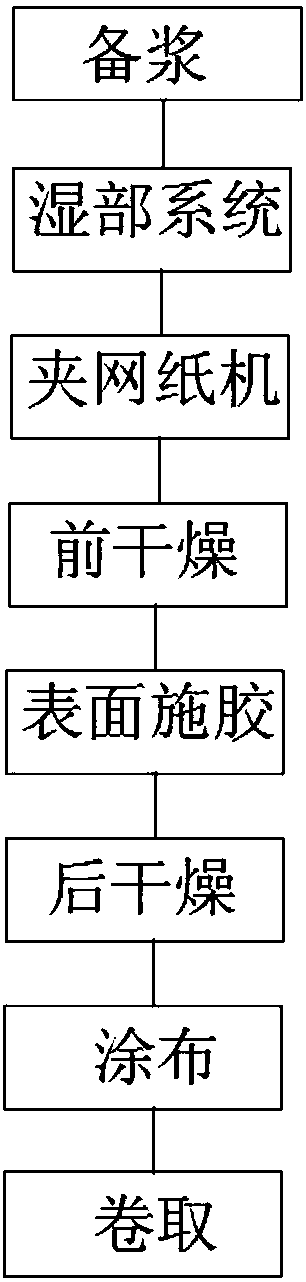

[0021] like figure 1 As shown, a papermaking method for in-machine coating of base paper for water transfer printing paper, including stock preparation, wet end system, sandwich paper machine, pre-drying, surface sizing, post-drying, coating, coiling and cutting, etc. , where the coating includes primer coating and top coating, and all sections are continuous production equipment connected to each other. Specific steps are as follows:

[0022] 1) Stock preparation: bleached kraft hardwood pulp, bleached kraft softwood pulp and chemical-mechanical pulp are all dispersed and refined at a concentration of 4%. Mix and prepare slurry at a ratio of 75%:15%:10%.

[0023] 2) Wet end: After the slurry is mixed, add 40kg / t wet strength agent at the entrance of the pulp tank. The addition of wet strength agent mainly improves the wet strength of the paper after soaking; then add 8kg / t positive starch at the outlet of the pulp tank, The main purpose is to improve the dry strength, and ...

Embodiment 2

[0034] A papermaking method for in-machine coating of base paper for water transfer printing paper base paper, the specific steps are as follows:

[0035] 1) Stock preparation: bleached kraft hardwood pulp, bleached kraft softwood pulp and chemical-mechanical pulp are all dispersed and refined at a concentration of 4%, and the freeness of refining is 450ml, 400ml, 350ml respectively, and then mixed The tubes are mixed with a ratio of 80%:15%:15%.

[0036] 2) Wet end: After the slurry is mixed, add 50kg / t of wet strength agent at the entrance of the pulp forming tank. The addition of wet strength agent mainly improves the wet strength of the paper after soaking; then add 10kg / t of positive starch at the exit of the pulp forming tank, The main purpose is to improve the dry strength, and the slurry enters the head box after being screened and purified;

[0037] 3) Sandwich paper machine: The sandwich paper machine includes head box, forming wire, and press section; the slurry is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com