A kind of manufacturing method of window protection panel with ag+ar+af coating

A technology for protecting panels and manufacturing methods, which is applied in the directions of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., and can solve the problem of poor light transmittance and chromatic aberration performance of products, unsatisfactory chromatic aberration performance, film voids or Problems such as falling off, achieve high light transmittance, improve binding force, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the window protection panel with AG+AR+AF coating is manufactured by the following method:

[0028] According to the size of the window protection panel, the window protection panel can be a mobile phone window protection screen or a computer display screen, and the light-transmitting tempered glass is selected to be processed into a light-transmitting substrate 1 of a corresponding size, and then cleaned, using Weakly alkaline sodium bicarbonate aqueous solution is carried out alkaline washing for 10 minutes, then, rinse with clean water and dry, and use in the next step after drying;

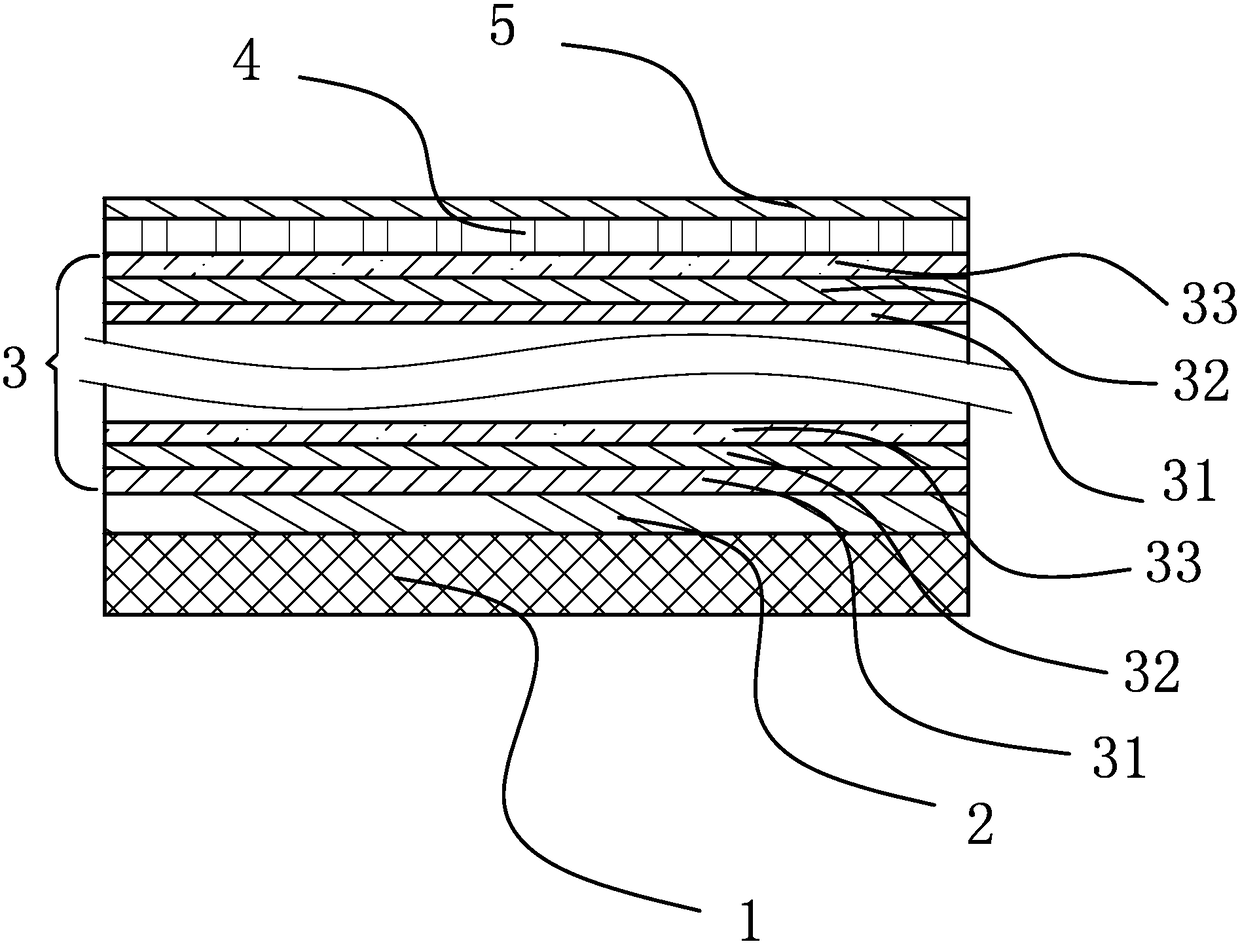

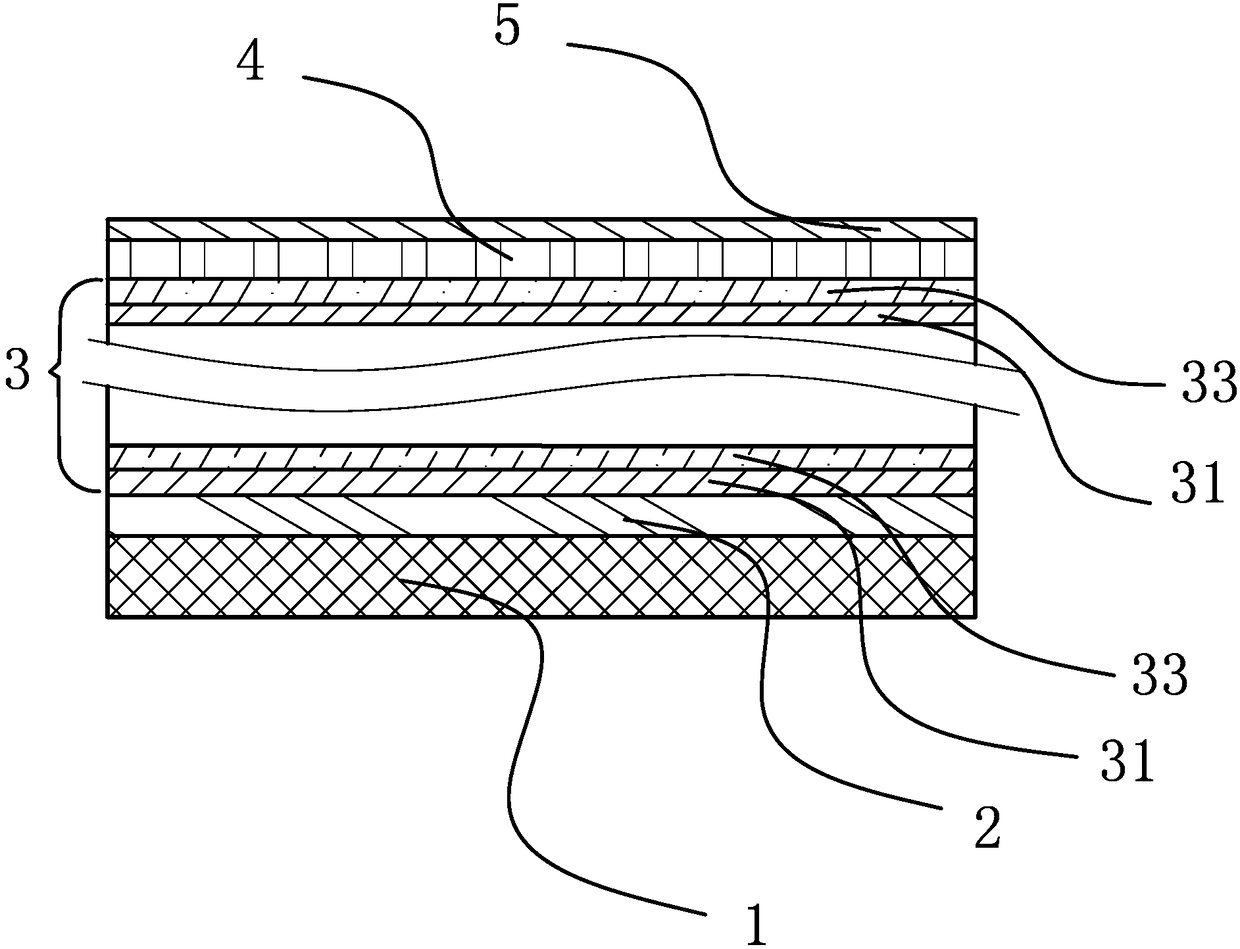

[0029] The upper surface of the light-transmitting substrate 1 is etched with an etching solution, and the haze of the upper surface of the tempered glass reaches 8% and the roughness Ra reaches ≤0.03 through detection, wherein the etching solution is an aqueous solution of HF and HCl, and the HF The mass content of HCl is 12%, the content of HCl is 5%, and the rest ...

Embodiment 2

[0032] In this embodiment, the specific preparation method of the window protection panel with AG+AR+AF coating is the same as that of Example 1, and will not be repeated here. The only difference is that the AR coating layer 3, the Al coating 2 o 3 Film 4 and coating AF film layer 5 are different from embodiment 1, and concrete coating mode is as follows:

[0033] The AR film layer 3 is vapor-deposited on the surface of the AG film layer 2, specifically: the light-transmitting substrate 1 with the AG film layer 2 is placed in the coating chamber of the vacuum coating machine, and then vacuumized and heated to make the coating chamber The ambient temperature in the room reaches 110°C, and the vacuum degree reaches 1.5x10 -3 Pa, then feed argon and oxygen, control the feed flow of argon to be 10sccm, and the flow of oxygen to be 40sccm, then, open the ZrO 2 The target source is evaporated so that a layer of ZrO is evaporated on the surface of the AG film layer 2 2 film 31, m...

Embodiment 3

[0035] The specific preparation method of the window protection panel with AG+AR+AF coating in this embodiment is the same as that in Embodiment 2, and will not be repeated here. The only difference is that the number of alternate repetitions of each film in the AR coating layer is different. The AR coating method is as follows:

[0036]The AR film layer 3 is vapor-deposited on the surface of the AG film layer 2, specifically: the light-transmitting substrate 1 with the AG film layer 2 is placed in the coating chamber of the vacuum coating machine, and then vacuumized and heated to make the coating chamber The ambient temperature in the room reaches 100°C, and the vacuum degree reaches 1.8x10 -3 Pa, then feed argon and oxygen, control the feed flow of argon to be 10sccm, and the flow of oxygen to be 40sccm, then, open the ZrO 2 The target source is evaporated so that a layer of ZrO is evaporated on the surface of the AG film layer 2 2 film 31, making ZrO 2 The thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com