Preparation method of cast iron roller for pinch roller of coiler

A pinch roll and coiler technology, which is applied in the field of strip steel rolling production equipment in the metallurgical industry, can solve the problems of poor thermal shock resistance, steel sticking on the surface of the roll, and limited thickness of the working layer, etc., to achieve long service life, Good room temperature, conducive to the effect of tissue production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

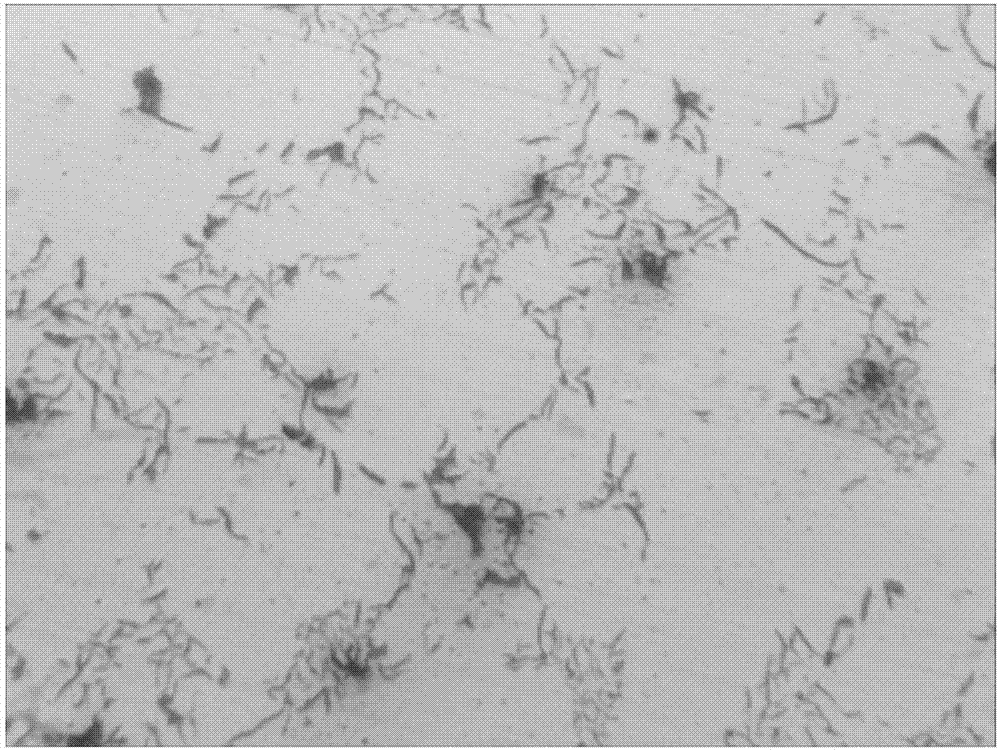

Image

Examples

Embodiment 1

[0029] 1) By weight percentage: C 2.5, Ni 0.5, Cr 3.8, Si 3.0, Nb 1.5, Mn 1.5, Mo 2.2, Cu0.1, W0, and the balance is Fe for ingredients; get commercially available pig iron with a purity of 99.9% metallic nickel, 99.9% pure metallic copper, 60% Cr ferrochrome, 75% Nb ferroniobium, 60% Mn ferromanganese, 60% Mo ferromolybdenum, 75% Si ferrosilicon , put into induction melting electric furnace, melted into alloy cast iron melt at 1450℃;

[0030] 2) Superheat the alloy cast iron melt obtained in step 1) to 1500°C, keep it warm for 30 minutes, and remove the surface slag; after that, adjust the temperature of the alloy cast iron melt to 1400°C;

[0031] 3) Remove the surface slag from the alloyed cast iron melt in step 2), add 0.5% Si in the form of ferrosilicon (75Si-Fe) in the ladle to obtain C 2.5, Ni 0.5, Cr 3.8, Si 3.5, Nb 1.5, Mn 1.5, Mo 2.2, Cu0.1, W0, alloy cast iron liquid with the balance being Fe; pouring out of induction melting electric furnace;

[0032] 4) Spray 1-...

Embodiment 2

[0038] 1) By weight percentage: C3.6, Ni5.0, Cr0.1, Si 1.0, Nb0.2, Mn 0.5, Mo 0.1, Cu 0.3, W1.7, and the balance is Fe for ingredients; Pig iron for sale, metallic nickel with a purity of 99.9%, metallic copper with a purity of 99.9%, metallic tungsten with a purity of 99.8%, ferrochromium with 60% Cr, ferro-niobium with 75% Nb, ferromanganese with 60% Mn, ferromanganese with 60% 60% Mo ferromolybdenum and 75% Si ferrosilicon are put into induction melting electric furnace and melted into alloy cast iron melt at 1450°C;

[0039] 2) Superheat the alloy cast iron melt obtained in step 1) to 1550°C, keep it warm for 20 minutes, and remove the surface slag; after that, adjust the temperature of the alloy cast iron melt to 1450°C;

[0040] 3) Remove the surface slag from the alloyed cast iron melt in step 2), and add 0.5% Si in the form of ferrosilicon (75Si-Fe) in the ladle to obtain C3.6, Ni 5.0, Cr0.1, Si 1.5 , Nb0.2, Mn0.5, Mo 0.1, Cu0.3, W 1.7, and the balance is Fe alloy cas...

Embodiment 3

[0046] 1) By weight percentage: C3.0, Ni3.0, Cr0.6, Si 2.0, Nb2.7, Mn 3.5, Mo 1.0, Cu 0.6, W0.5, and the balance is Fe for ingredients; Pig iron for sale, metallic nickel with a purity of 99.9%, metallic copper with a purity of 99.9%, metallic tungsten with a purity of 99.8%, ferrochromium with 60% Cr, ferro-niobium with 75% Nb, ferromanganese with 60% Mn, ferromanganese with 60% 60% Mo ferromolybdenum and 75% Si ferrosilicon are put into induction melting electric furnace and melted into alloy cast iron melt at 1450°C;

[0047] 2) Superheat the alloy cast iron melt obtained in step 1) to 1530°C, keep it warm for 25 minutes, and remove the surface slag; after that, adjust the temperature of the alloy cast iron melt to 1420°C;

[0048] 3) Remove surface slag from the alloyed cast iron melt in step 2), add 0.5% Si in the form of ferrosilicon (75Si-Fe) in the ladle to obtain C3.0, Ni 3.0, Cr0.6, Si 2.5 , Nb2.7, Mn3.5, Mo 1.0, Cu0.6, W 0.5, and the balance is Fe alloy cast iron l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com