Narrowband organic-inorganic hybrid red light emitting material and preparation method for same

A technology for narrow-band emission and luminescent materials, applied in luminescent materials, copper organic compounds, chemical instruments and methods, etc., to achieve the effects of easy preparation, high yield, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

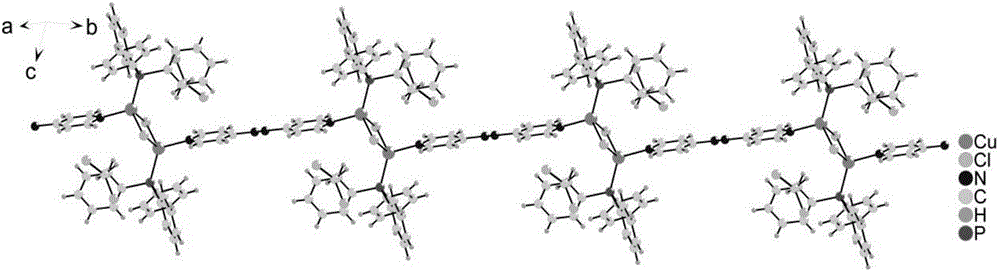

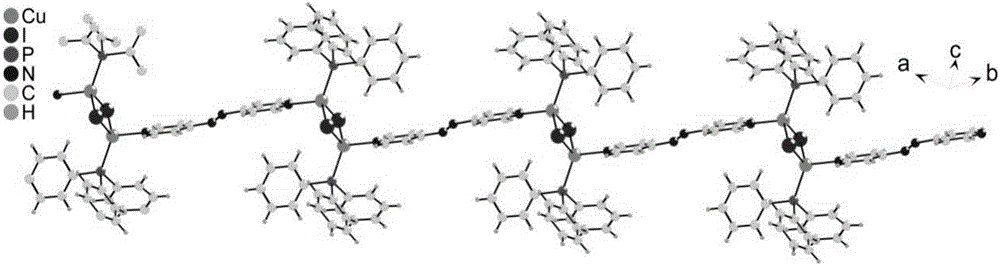

[0037] Example 1 (X = Cl)

[0038] Weigh 0.0623gCu(PPh 3 ) 2 Dissolve Cl (0.010mol) in 3.0ml of dichloromethane to obtain a colorless solution, put it into a test tube, add 3.0ml of methanol / dichloromethane (1:1), and finally add 0.0184g of 4,4'-azopyridine (0.010mol) Red solution in 3.0 ml of methanol and the layers were allowed to separate. A few days later, a large number of black crystals were formed. After filtration, a large number of black blocky crystals were obtained, washed with anhydrous ether, and dried in air. The yield was 0.0441g, and the yield was 82%. Elemental Analysis Calc.For C 24 h 21 Cl 3 CuN 2 P(%): C53.55, H 3.93, N 5.20. Found(%): C 53.70, 7H 3.89, N 5.15. FT-IR (KBr pellet, cm -1 ): 3071(w), 2925(w), 1631(m), 1596(m), 1569(m), 1478(m), 1433(s), 1416(m), 1384(m), 1230(w ), 1182(w), 1094(m), 1027(w), 848(m), 835(m), 745(m), 695(s), 574(m), 522(s), 504(m ), 491(m).

Embodiment 2 X

[0039] Example 2 (X = Cl)

[0040] A large amount of synthesis: weigh 0.6238gCu(PPh 3 ) 2 Cl (0.986mmol) was dissolved in 15.0ml of dichloromethane to obtain a colorless solution, and finally a red solution of 0.1843g of 4,4'-azopyridine in 15.0ml of methanol was added and stirred to obtain a red solution. A few days later, a large number of black crystals were formed. After filtration, a large number of black blocky crystals were obtained, washed with anhydrous ether, and dried in air. The yield was 0.4512g, and the yield was 85%.

Embodiment 3 X

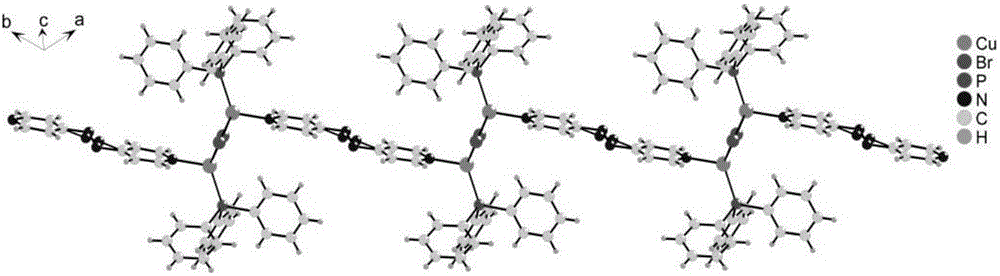

[0041] Example 3 (X = Br)

[0042] Weigh 0.0672gCu(PPh 3 ) 2 Dissolve Br (0.010mmol) in 3.0ml of dichloromethane to obtain a colorless solution, put it into a test tube, add 3.0ml of methanol / dichloromethane (1:1), and finally add 0.0184g of 4,4'-azopyridine (0.010mmol) Red solution in 3.0 ml of methanol and the layers were allowed to separate. A few days later, a large number of black crystals were formed. After filtration, a large number of black blocky crystals were obtained, washed with anhydrous ether, and dried in air. The yield was 0.0391g, and the yield was 78%. Elemental Analysis Calc. for C 23 h 19 BrCuN 2 P(%): C55.49, H 3.85, N 5.63. Found(%): C 55.34, H 3.91, N 5.27.FT-IR (KBr pelletcm -1): 3072(w), 1632(m), 1597(m), 1479(m), 1433(s), 1415(m), 1384(w), 1229(w), 1161(w), 1110(w ), 1095(m), 1057(w), 1045(w), 1028(w), 848(m), 750(s), 696(s),545(m), 522(s), 504(m ), 489(m).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com