Preparation method of anhydrous citric acid with specific granularity

A technology of anhydrous citric acid and citric acid, applied in organic chemical methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem that citric acid cannot be effectively controlled in the crystallization process, increase the cost of citric acid preparation, and increase the production workshop Energy consumption and other issues, to achieve the effect of eliminating adverse effects, avoiding uneven crystal particle size, and improving enterprise production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

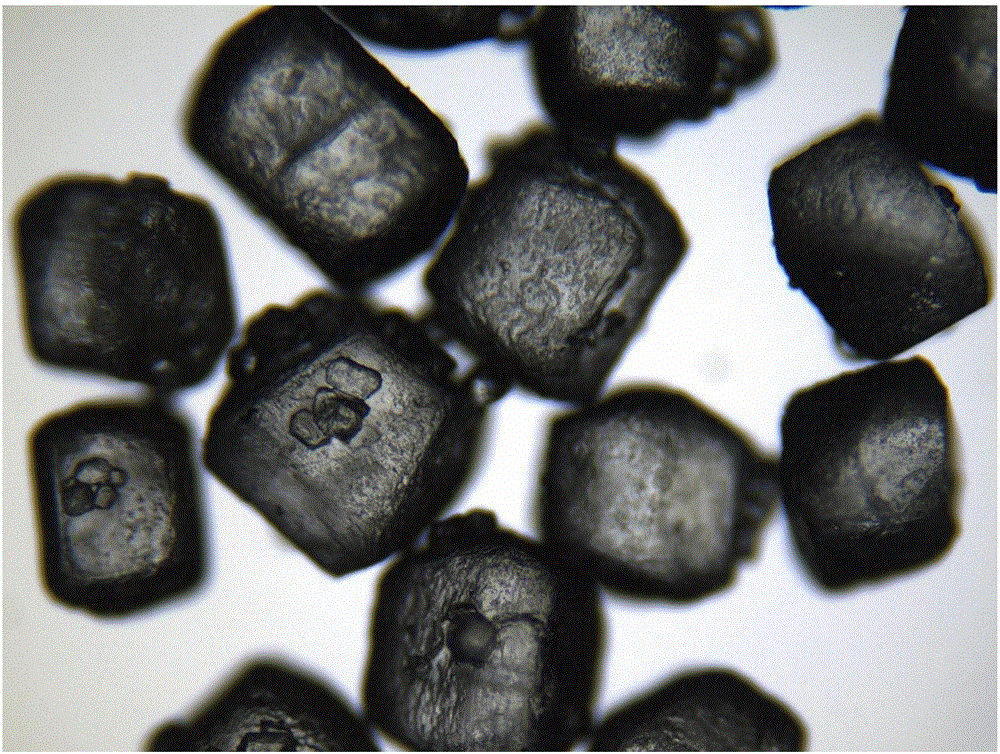

Embodiment 1

[0044] Prepare the anhydrous citric acid product with a particle size of 20-40 meshes required by the customer.

[0045] The citric acid acid solution obtained after calcium salt neutralization and sulfuric acid acid hydrolysis is subjected to ion exchange through continuous separation equipment to remove various pigments and anion and cation impurities. After separation treatment, the permeability of the separation solution Luminosity is 99.6%, Cl - , SO 4 2- , Fe 3+ The content is less than 0.5mg / L, and the acidity is 55%.

[0046] Concentrating and evaporating the off-transaction liquid to obtain a multi-effect concentrate, the relative density of the multi-effect concentrate is 1360kg / m 3 , with an acidity of 104%.

[0047] will be 5m 3 The multi-effect concentrate is added to the crystallizer for concentrated crystallization. The initial temperature of the concentrate is 55°C, the crystallization vacuum is 0.092MPa, and the evaporation temperature is 61°C. When the...

Embodiment 2

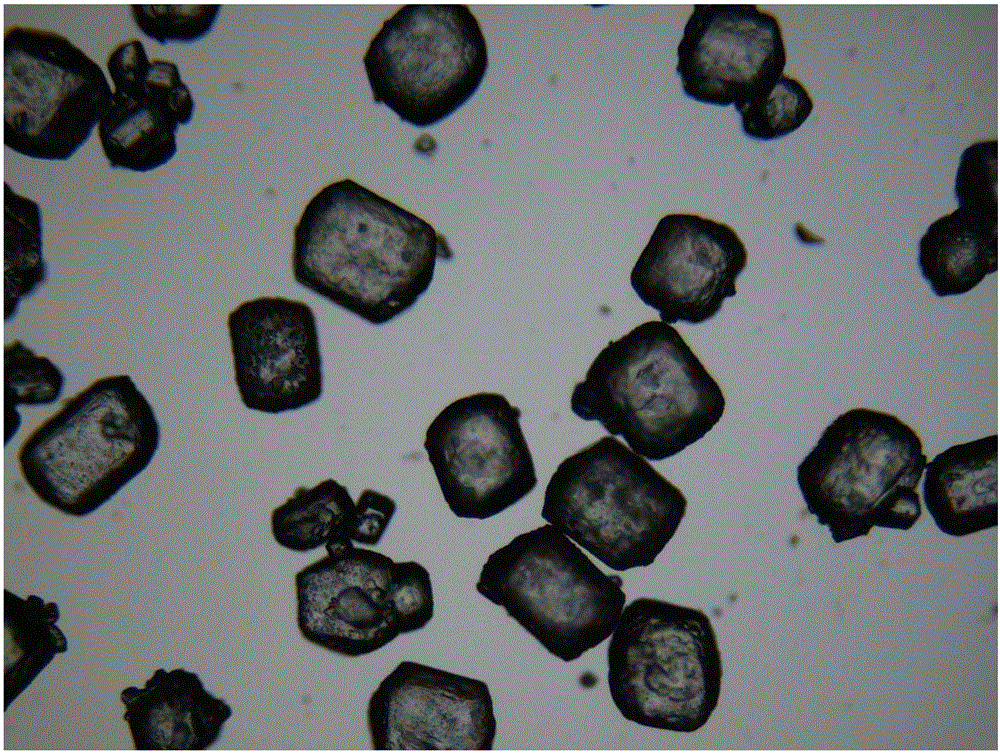

[0052] Prepare the anhydrous citric acid product with a particle size of 30-60 meshes required by the customer.

[0053] The citric acid acid solution obtained after calcium salt neutralization and sulfuric acid acid hydrolysis is subjected to ion exchange through continuous separation equipment to remove various pigments and anion and cation impurities. After separation treatment, the permeability of the separation solution Luminosity is 99.8%, Cl - , SO 4 2- , Fe 3+ The content is less than 0.4mg / L, and the acidity is 53%.

[0054] Concentrating and evaporating the off-transaction liquid to obtain a multi-effect concentrated liquid with a relative density of 1370kg / m 3 , with an acidity of 106%.

[0055] will be 6.4m 3 The multi-effect concentrate is added to the crystallizer for concentrated crystallization. The initial temperature of the concentrate is 53°C, the crystallization vacuum is 0.091MPa, and the evaporation temperature is 62°C. When the solution supersatur...

Embodiment 3

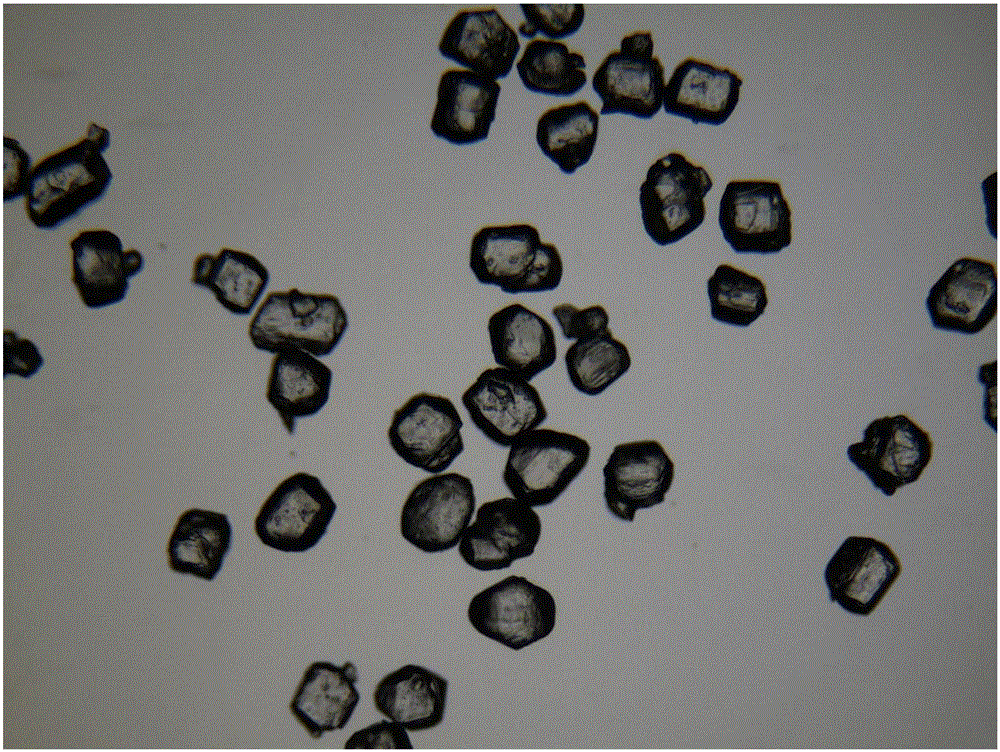

[0060] Prepare the anhydrous citric acid product with a particle size of 40-60 meshes required by the customer.

[0061] The citric acid acid solution obtained after calcium salt neutralization and sulfuric acid acid hydrolysis is subjected to ion exchange through continuous separation equipment to remove various pigments and anion and cation impurities. After separation treatment, the permeability of the separation solution Luminosity is 99.8%, Cl - , SO 4 2- , Fe 3+ The content is less than 0.3mg / L, and the acidity is 58%.

[0062] Concentrating and evaporating the off-transaction liquid to obtain a multi-effect concentrate, the relative density of the multi-effect concentrate is 1385kg / m 3 , with an acidity of 105%.

[0063] will be 6m 3 The multi-effect concentrate is added to the crystallizer for concentrated crystallization. The initial temperature of the concentrate is 53°C, the crystallization vacuum is 0.090MPa, and the evaporation temperature is 63°C. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com