Method for preparing low carbon olefins by catalytically pyrolyzing n-butane through metal chromium framework doped molecular sieve

A low-carbon olefin, catalytic cracking technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of not being efficiently utilized, and achieve low cost, high-efficiency conversion, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

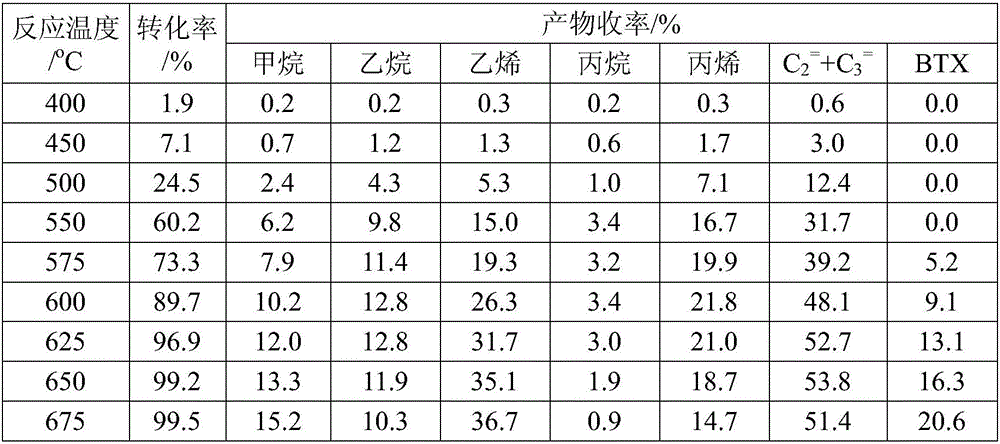

Embodiment 1

[0042] This embodiment provides a metal chromium framework doped ZSM-5 molecular sieve catalyst, wherein SiO 2 / (Cr 2 o 3 +Al 2 o 3 ) molar ratio is 80, Cr 2 o 3 / Al 2 o 3 The molar ratio is 1 / 25, and the metal chromium framework doped ZSM-5 molecular sieve catalyst is prepared by the following steps:

[0043] (1) Mix silica sol with a mass content of 40% and concentrated sulfuric acid, then add chromium nitrate nonahydrate, and stir at a constant temperature of 35° C. for 30 minutes to mix them uniformly to obtain a first mixed solution;

[0044] (2) dissolving aluminum sulfate octadecahydrate in deionized water, then adding it dropwise to the first mixed solution, and stirring at a constant temperature of 35° C. for 30 minutes to mix them uniformly to obtain a second mixed solution;

[0045] (3) Dissolve the template agent tetrapropylammonium bromide in deionized water, then add it dropwise to the second mixed solution, and stir at 35°C for 30 minutes to mix them eve...

Embodiment 2

[0054] The present embodiment provides a metal chromium skeleton doped ZSM-5 molecular sieve catalyst, which is denoted as 2# catalyst, wherein SiO 2 / (Cr 2 o 3 +Al 2 o 3 ) molar ratio is 80, Cr 2 o 3 / Al 2 o 3 The molar ratio is 1 / 10, and the preparation steps of the metal chromium skeleton doped ZSM-5 molecular sieve catalyst are the same as those in Example 1, the difference is only in the content of metal chromium.

[0055] The method of using the catalyst to catalytically crack n-butane to produce low-carbon olefins, and the detection and analysis method of the reaction product are all the same as in Example 1.

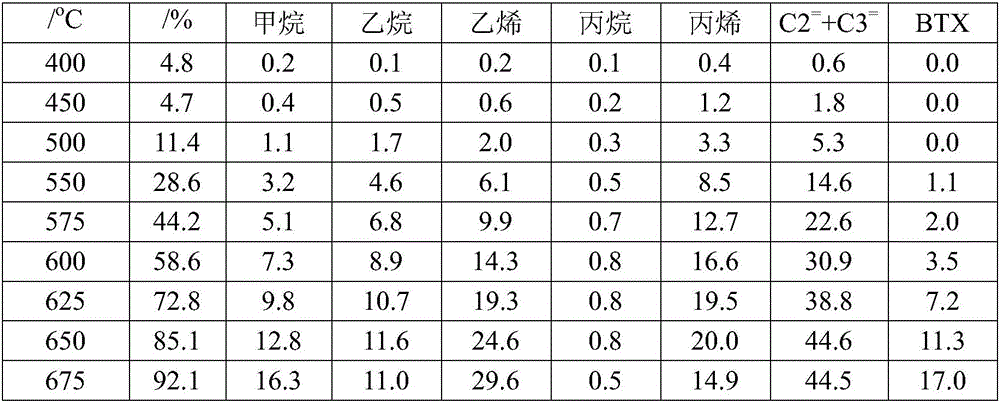

[0056] Table 2 shows the catalytic cracking reaction results and the yield of main products of 2# catalyst.

[0057] Table 2 Yield distribution of main products of n-butane catalytic cracking reaction (2#)

[0058]

[0059]

Embodiment 3

[0061] The present embodiment provides a metal chromium framework doped ZSM-5 molecular sieve catalyst, denoted as 3# catalyst, wherein SiO 2 / (Cr 2 o 3 +Al 2 o 3 ) molar ratio is 80, Cr 2 o 3 / Al 2 o 3 The molar ratio is 1 / 10, and the preparation steps of the metal chromium skeleton doped ZSM-5 molecular sieve catalyst are the same as those in Example 1, the difference is only in the content of metal chromium.

[0062] The method of using the catalyst to catalytically crack n-butane to produce low-carbon olefins, and the detection and analysis method of the reaction product are all the same as in Example 1.

[0063] The results of the catalytic cracking reaction and the yield of main products of catalyst 3# are shown in Table 3.

[0064] Table 3 Yield distribution of main products in n-butane catalytic cracking reaction (3#)

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com