Rotary exchange groove type multi-material mask exposal additive manufacturing device and method

A kind of additive manufacturing and multi-material technology, which is applied in the field of multi-material surface exposure additive manufacturing device of rotary tank changer, can solve the problem that the photocuring prototype technology is difficult to apply to the multi-material processing field, so as to improve the processing control process, The effect of shortening processing time and high technology promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

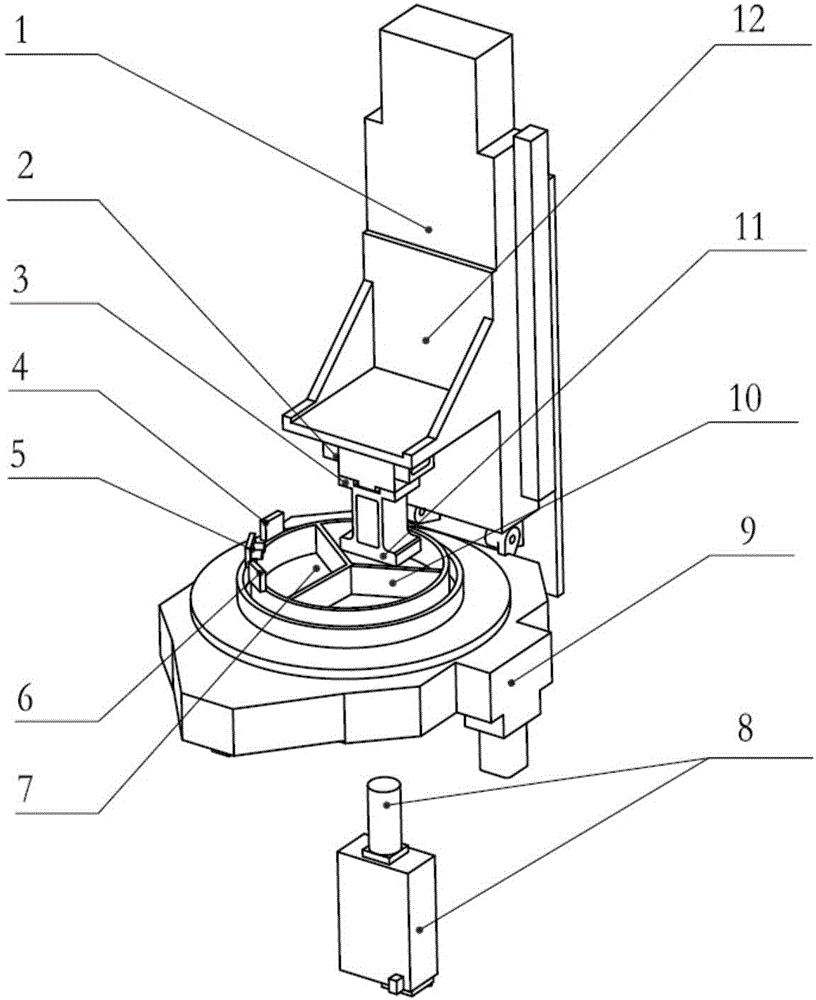

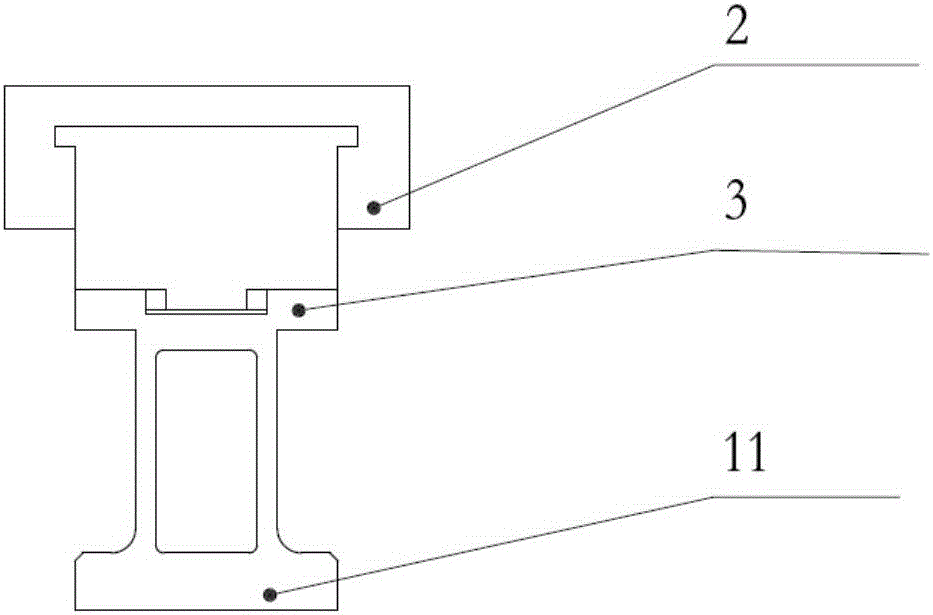

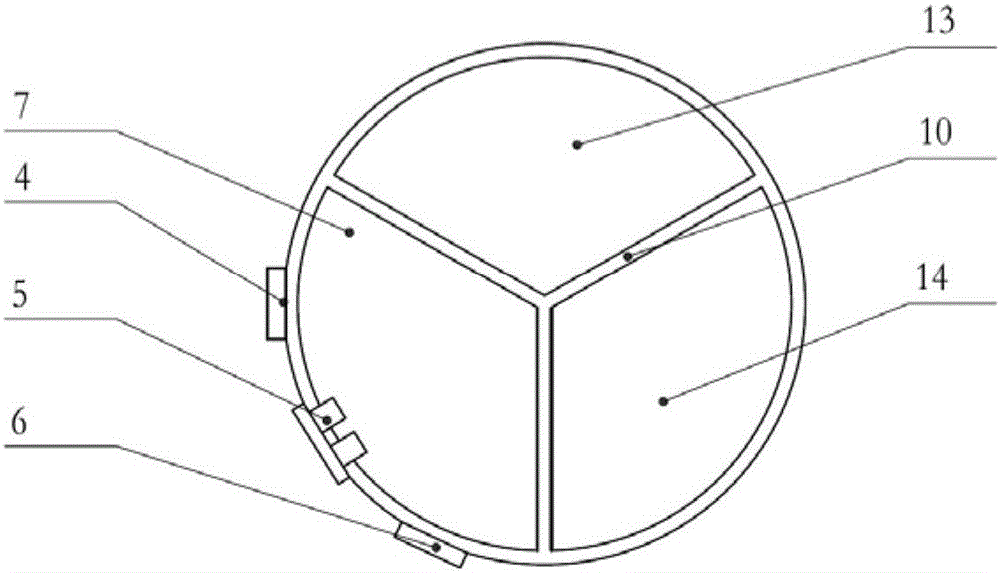

[0025] The device part can be divided into processing module, exposure module and control module. The processing module includes a Z-axis translation mechanism (including a worktable support, a central adjustment mechanism and a manual disassembly mechanism), and a partitioned feeding trough (including an ultrasonic distance measuring sensor, a drying fan, a cleaning steering gear, and a rotation mechanism). The exposure module includes UVLED light source, DMD chip and its driving circuit, and projection lens. The control module includes a processing control module and an exposure control module, including multi-material processing slot change algorithm and mask change algorithm. The above-mentioned Z-axis translation mechanism is fixed on the frame and is perpendicular to the frame reference plane. A workbench support is fixed on the Z-axis translation platform.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com