A New High Efficiency Willow Splitter

A high-efficiency, willow splitting machine technology, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of difficult to grasp the size of the division, unsafe manual operation, hidden safety hazards, etc., to achieve the balance of clamping force and ensure clamping. effect, high pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

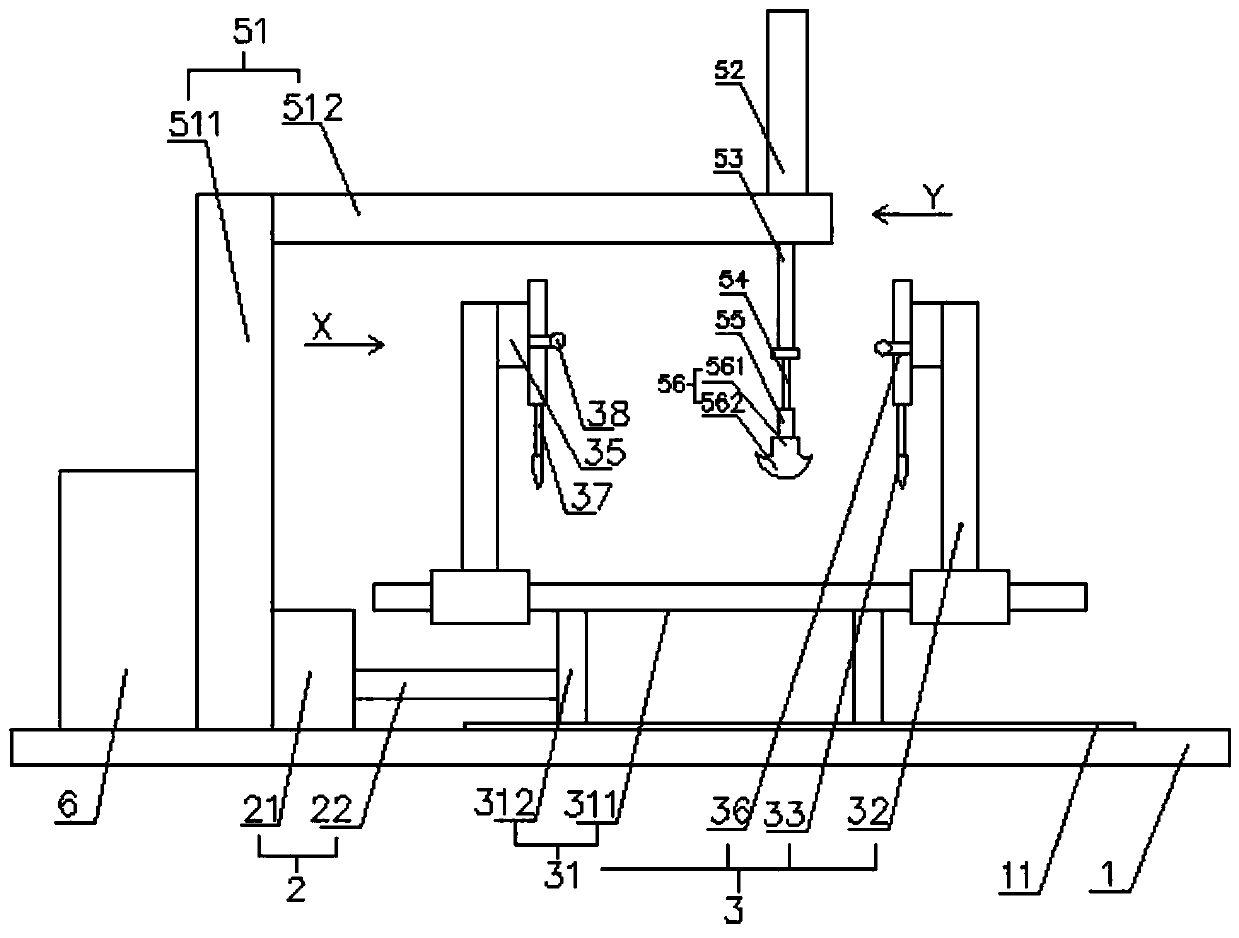

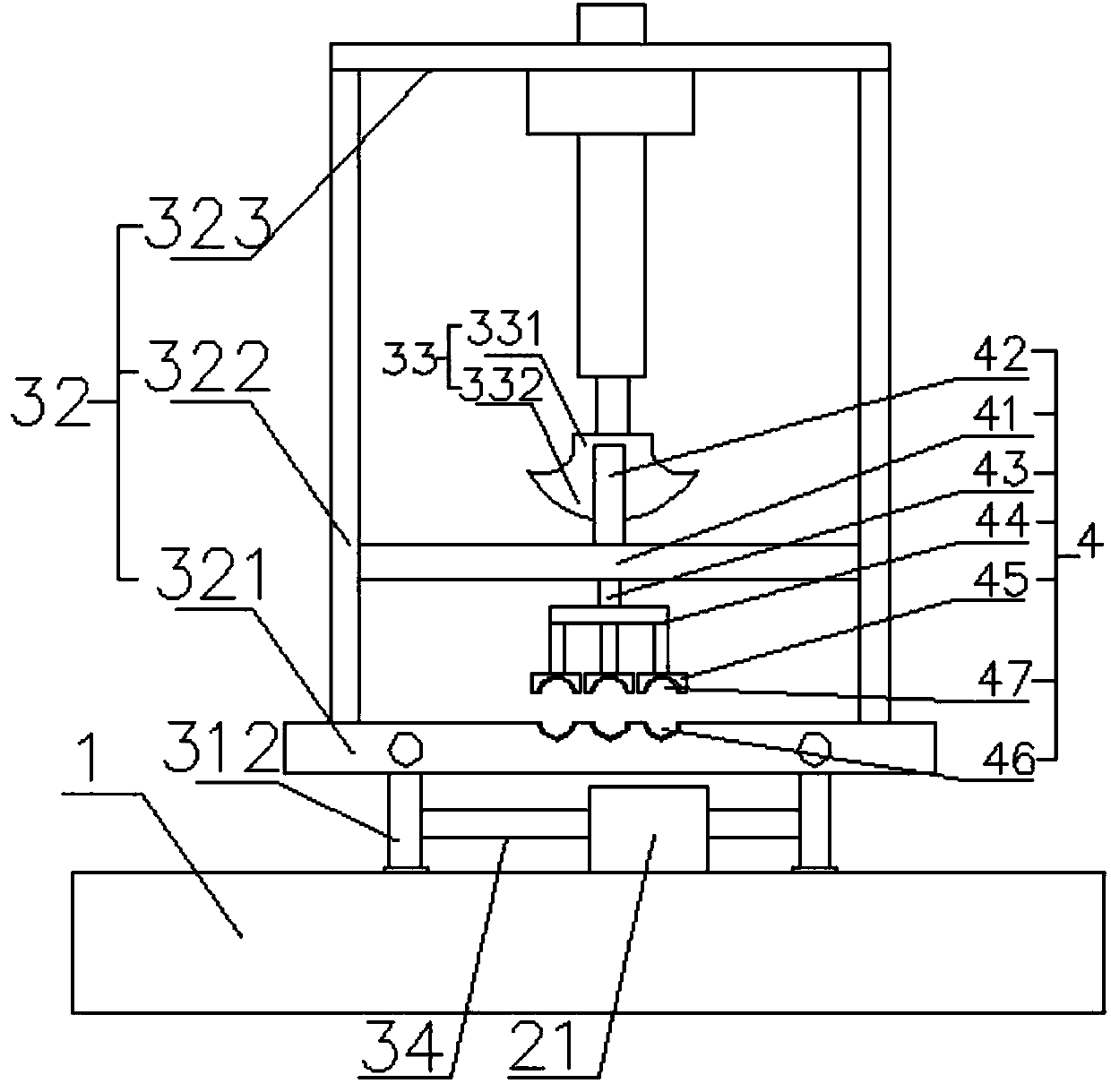

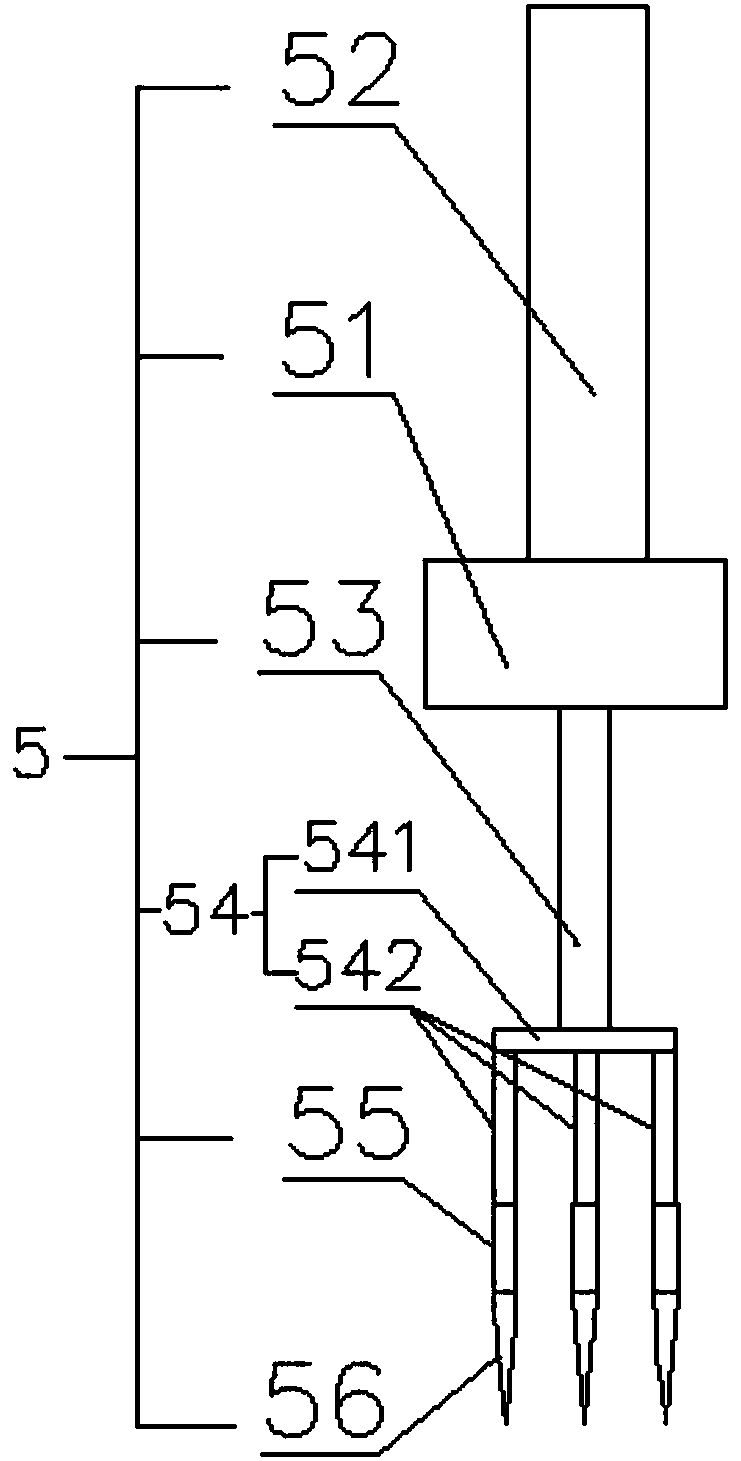

[0036] A new type of high-efficiency willow splitter, which includes a working platform, a cutting arm, a cutting tool, a clamping tool, a pushing tool, and a control cabinet; the working platform is in a square structure, and the cutting arm, the cutting tool, and the clamping tool are , pushing tooling and control cabinet are all arranged on the described work platform, two slideways are arranged in parallel on the described working platform, and the described pushing tooling is arranged on the described slideway; The described pushing tooling comprises a motor and a pushing cross bar; One end of the push bar is connected to the motor, and the other end is connected to the cutting tool;

[0037] The cutting tool includes a bottom bracket, a cutting bracket and a cutting tool; the bottom bracket includes two long horizontal bars arranged in parallel, and the bottoms of the two long horizontal bars are provided with two rectangular sliders, and the bottom of the sliders Fitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com