A kind of production and processing technology of optical module shell

A processing technology and technology for optical modules, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of coating damage, poor air tightness and firmness, and high production cost of optical module housings, and reduce production and processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The production and processing technology of an optical module housing of the present invention will be further described in detail in conjunction with specific implementation methods:

[0034] The production and processing technology of a kind of optical module shell of the present invention comprises the following steps:

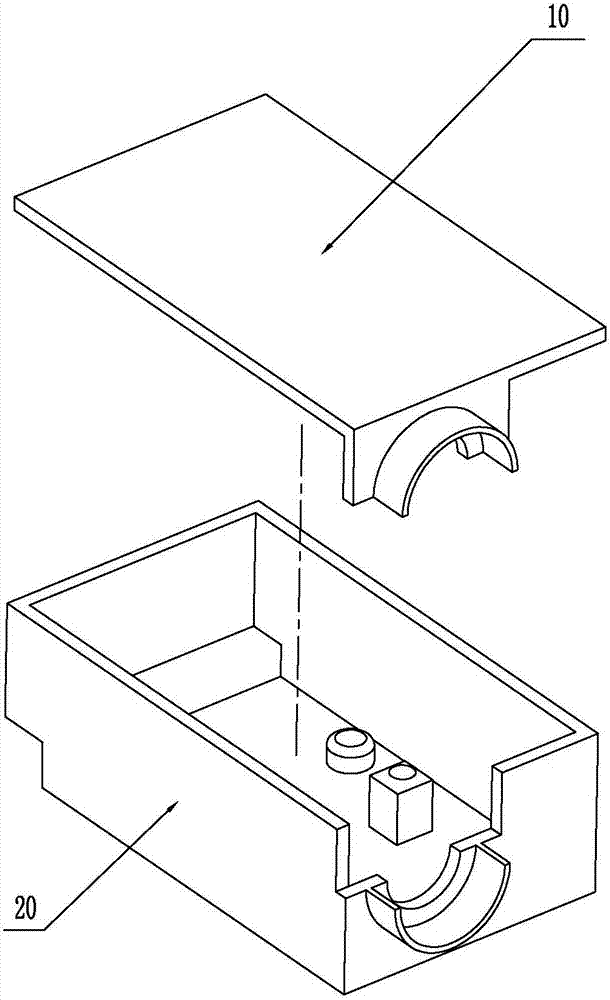

[0035] (1) Zinc alloy material is used to die-cast the optical module housing through die-casting process, see figure 1 , to obtain a cover plate 10 with a thickness of 0.4-0.55 mm and a base 20 with a thickness of 0.6-0.8 mm. The thickness of the cover plate 10 and the base 20 should not be too thin. The most suitable thickness is 0.6-0.8 mm, otherwise the cover plate 10 and the base 20 will be deformed during die-casting, which is not conducive to parallel seam welding, and too thick will increase the cost;

[0036] (2) The surfaces of the cover plate 10 and the base 20 are all nickel-plated, and the thickness of the nickel plating is 18 μm, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com