Friction stir welding tool and angle adjustment method based on laser ranging and attitude feedback

A technology of laser distance measurement and friction stirring, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as difficult maintenance, low overload capacity, and welding seam tail defects, so as to simplify the structure of welding tools and realize Fast positioning, good indentation depth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

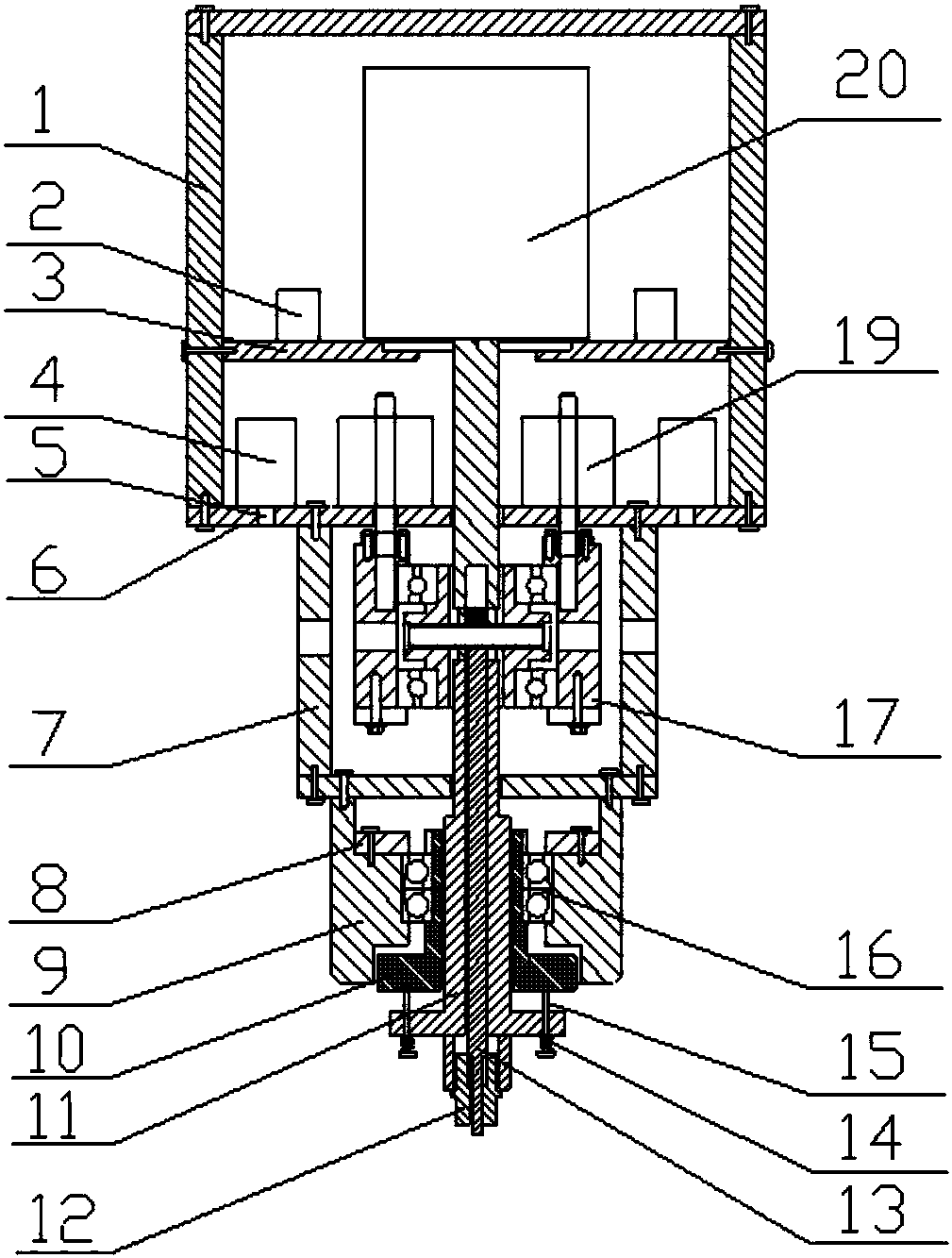

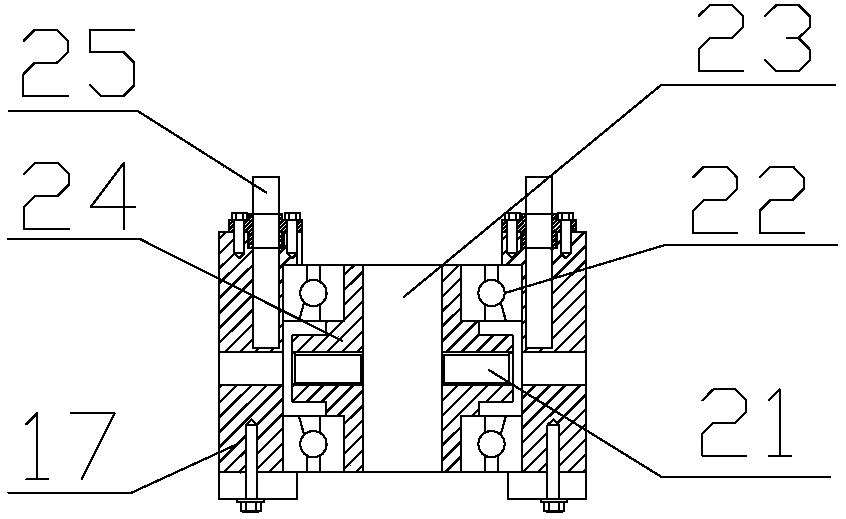

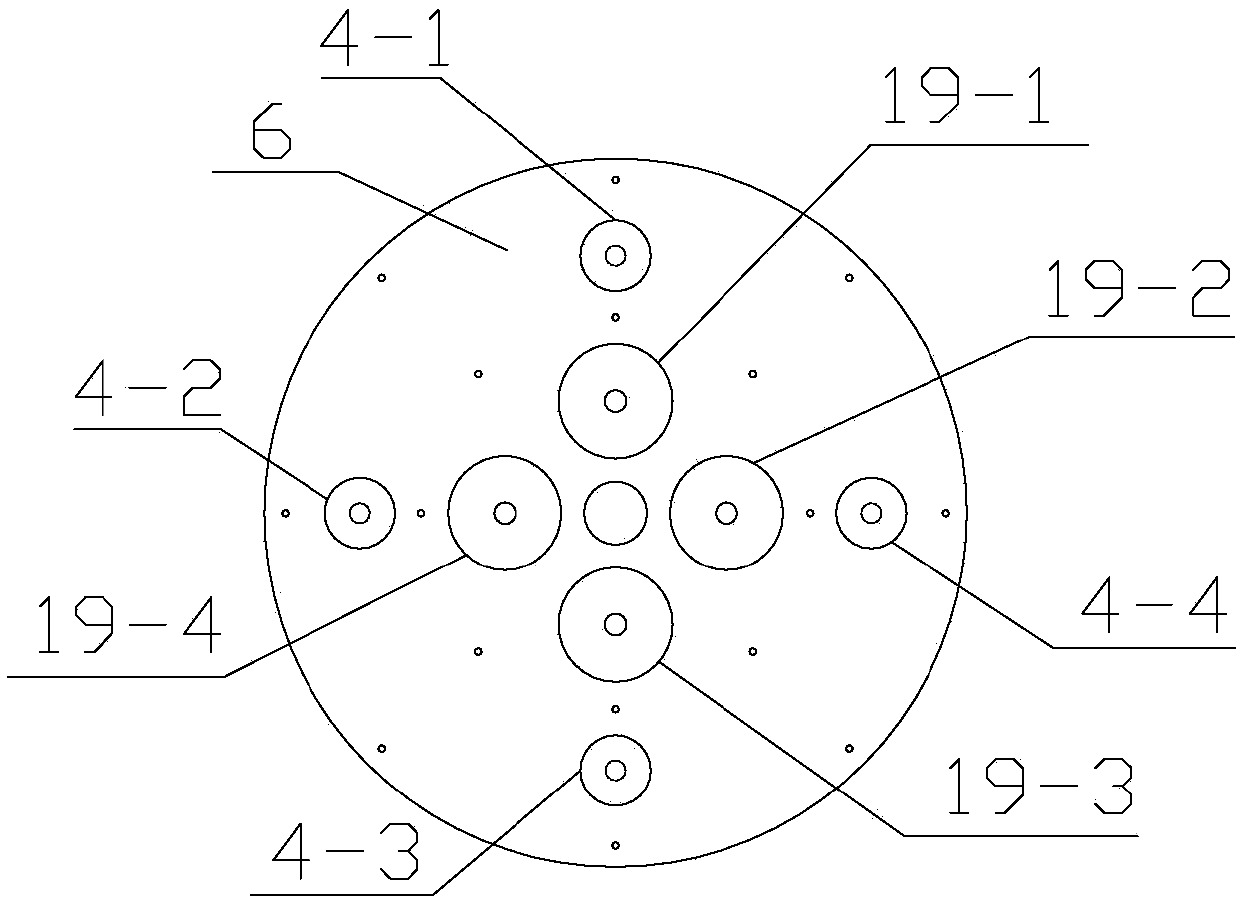

[0024] Such as Figure 1 to Figure 4 As shown, a friction stir welding tool based on laser distance measurement and attitude feedback of the present invention includes a power chamber shell 1, and a first support plate 3 and a second support plate 6 are sequentially arranged inside the power chamber shell 1, so that The center of the first support plate 3 is equipped with a main motor 20, the motor shaft of the main motor 20 passes through the second support plate 6, and four attitude sensors 2 are also installed on the first support plate 3, and on the second support plate 6 There are four moving devices that drive the slider 17 to move up and down and four laser distance measuring devices 4 evenly distributed around the axial circumference of the motor shaft. The rotary sleeve 24 is connected, and the synchronous rotary sleeve 24 is provided with a radial threaded hole 21, and the radial threaded hole 21 is screwed into a screw to be fixedly connected with the stirring needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com