Cutter for lathe machining of flat-bottom holes

A flat-bottom hole and turning technology, which is applied to the lathe tools, turning equipment, cutting blades, etc., can solve the problems of difficult chip removal, poor tool rigidity, and low efficiency, and achieve low manufacturing costs, guaranteed hole diameter, and tool structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

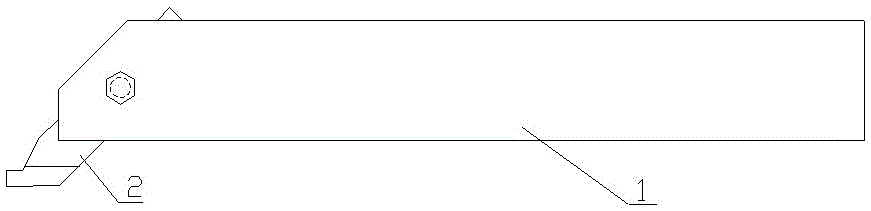

[0024] see figure 1 . A tool for turning flat-bottomed holes, comprising a tool holder 1 and a tool body 2 .

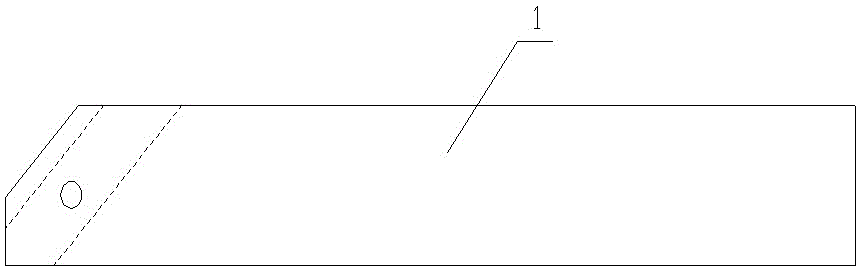

[0025] see figure 2 . The cutter bar 1 is a square body, and the front section of the cutter bar 1 is provided with an oblique square hole.

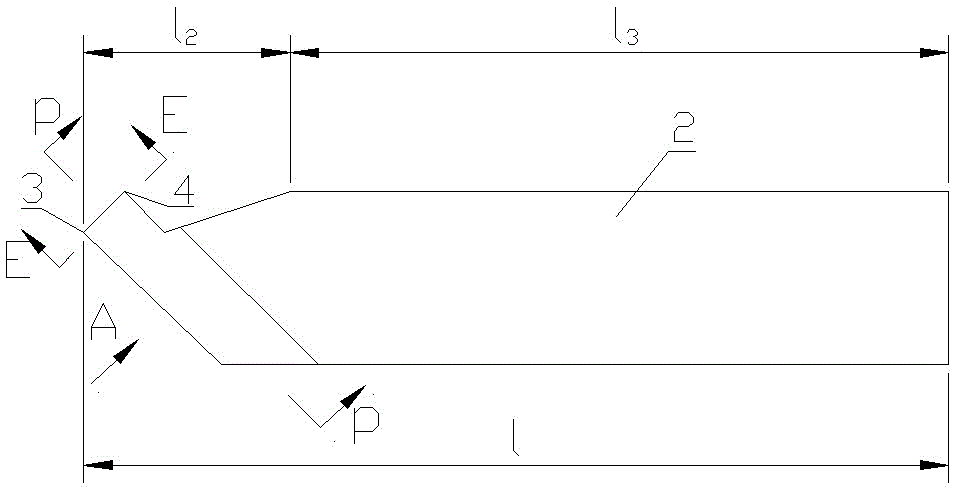

[0026] see image 3 . The cutter body 2 is a three-sided blade flat body turning tool installed in the oblique square hole of the cutter bar 1, and is fixed on the cutter bar 1 by bolts. The overall length l of the cutter body 2 is 65mm, including the edge groove portion l 2 and handle l 3 , handle l 3 The length of the blade is 45~55mm; 3 , including the working part and the non-working part, the length is 10-20mm.

[0027] see Figure 4 , Figure 5 , Image 6 . The rake angle of the tip of the cutter body 2 is 2°, and the relief angle α is 4-6°. The left and right sides of the front cutting edge 5 of the tip are the left cutting edge 6 and the right cutting edge 7, and the relief angle α1 of the left cutting ed...

Embodiment 2

[0031] The working principle of the present invention:

[0032] see Figure 7 , Figure 8 , Figure 9 . The front cutting edge 5 of the cutter body 2 performs longitudinal feed cutting parallel to the cutting spindle of the machine tool. At the same time, the front cutting edge 5 of the cutter body 2 starts from the inner diameter of the machined part for transverse feed cutting. The initial cutting rake angle is discharged from the arc groove between the cutting edge 6 and the right cutting edge 7, and the whole process of flat-bottomed hole machining is completed by feeding layer by layer, where α1 is related to the diameter of the inner hole to be processed, the smaller the inner hole diameter, The bigger α1 is.

[0033] In addition, some flat-bottomed holes need to have rounded corners at the root, and the left tip 3 and right tip 4 of the tool can be ground into a suitable rounded corner shape. Such knives are variants of the present special knives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com