A Composite Strengthening Method for Upsetting and Bulging of Generator Guard Ring

A bulging and upsetting technology, used in engine components, mechanical equipment, forging/pressing/hammering machinery, etc., can solve problems such as waste products, and achieve the effect of small residual stress, effective strengthening effect, and large deformation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

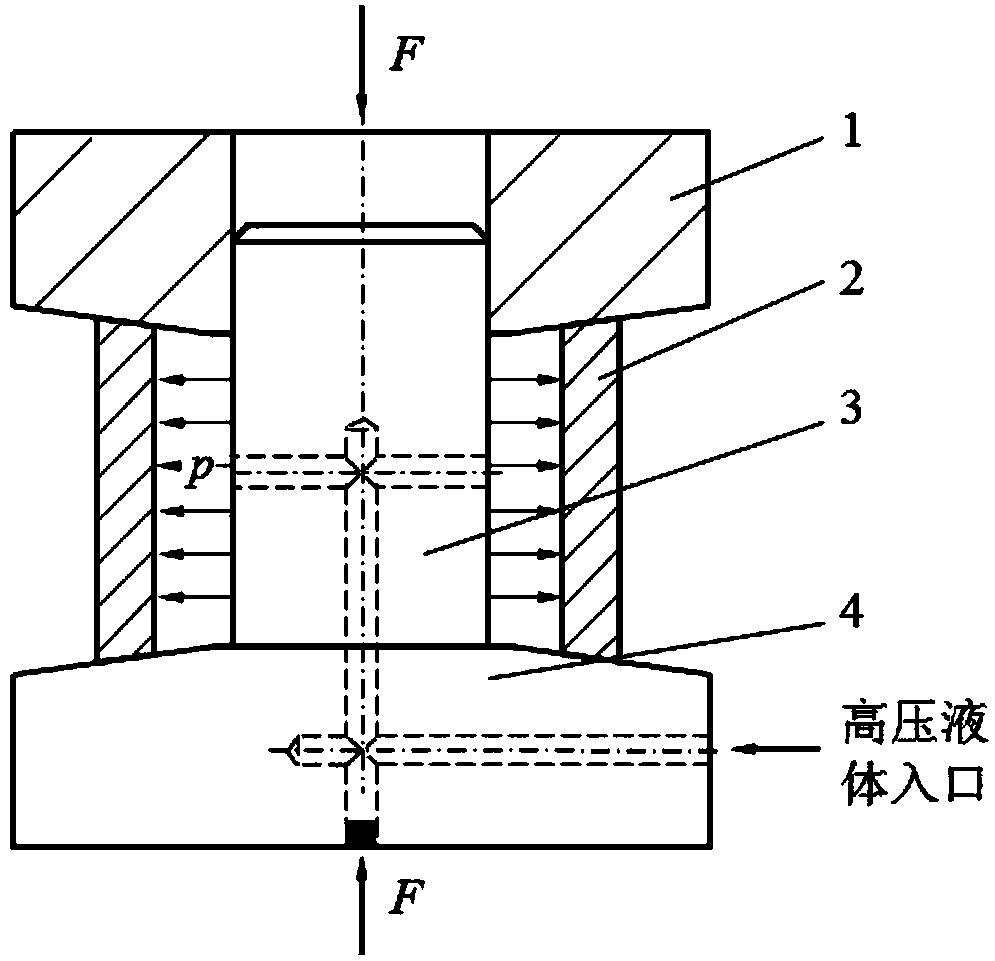

[0038] During the strengthening process of the retaining ring, the axial strain is taken as -0.2, and the corresponding tangential strain of the inner diameter of the retaining ring blank is 0.315. Therefore, the height of the retaining ring blank can be obtained as 977.1, the outer diameter of the retaining ring blank is 912.2, and the outer diameter of the retaining ring blank is 609.6 from the volume constant condition. The above data is properly rounded according to the principle of reserving a certain machining allowance: the height of the retaining ring blank is 980mm, the inner diameter is 610mm, and the outer diameter is 915mm. Adjust the pressing speed of the press and the flow rate of the high-pressure liquid into the inner cavity of the retaining ring blank, so that the pressing speed of the upper die matches the increasing speed of the inner wall or (outer wall) diameter of the retaining ring blank, and the performance and size meet the requirements. guard ring.

Embodiment 2

[0040] The dimensions and requirements of the retaining ring are the same as in Example 1. During the strengthening process of the retaining ring, the axial strain is taken as -0.25, and the corresponding tangential strain of the outer diameter of the retaining ring blank is 0.297. Therefore, the height of the blank of the retaining ring is 1027.2, the outer diameter of the blank of the retaining ring is 928.8, and the inner diameter of the blank of the retaining ring is 651.6 from the condition of constant volume. The above data is properly rounded according to the principle of reserving a certain machining allowance: the height of the retaining ring blank is 1030mm, the inner diameter is 760mm, and the outer diameter is 1015mm. Adjust the pressing speed of the press and the flow rate of the high-pressure liquid into the inner cavity of the retaining ring blank, so that the pressing speed of the upper die matches the increasing speed of the inner wall or (outer wall) diameter...

Embodiment 3

[0042] During the strengthening process of the retaining ring, the axial strain is taken as -0.28, and the corresponding tangential strain of the outer diameter of the retaining ring blank is 0.272. Therefore, the height of the blank of the retaining ring is 1058.5, the outer diameter of the blank of the retaining ring is 952.3, and the inner diameter of the blank of the retaining ring is 694.1 from the condition of constant volume. The above data is properly rounded according to the principle of reserving a certain machining allowance: the height of the retaining ring blank is 1065mm, the inner diameter is 780mm, and the outer diameter is 1018mm. Adjust the pressing speed of the press and the flow rate of the high-pressure liquid into the inner cavity of the retaining ring blank, so that the pressing speed of the upper die matches the increasing speed of the inner wall or (outer wall) diameter of the retaining ring blank, and the performance and size meet the requirements. gu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com