Beneficiation process of lead-zinc-silver ore and flotation reagent thereof

A technology of silver ore, lead and zinc, applied in flotation, solid separation, chemical instruments and methods, etc., can solve the problems of high cost of beneficiation process, consumption of flotation reagents, difficult beneficiation, etc. The effect of good effect and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

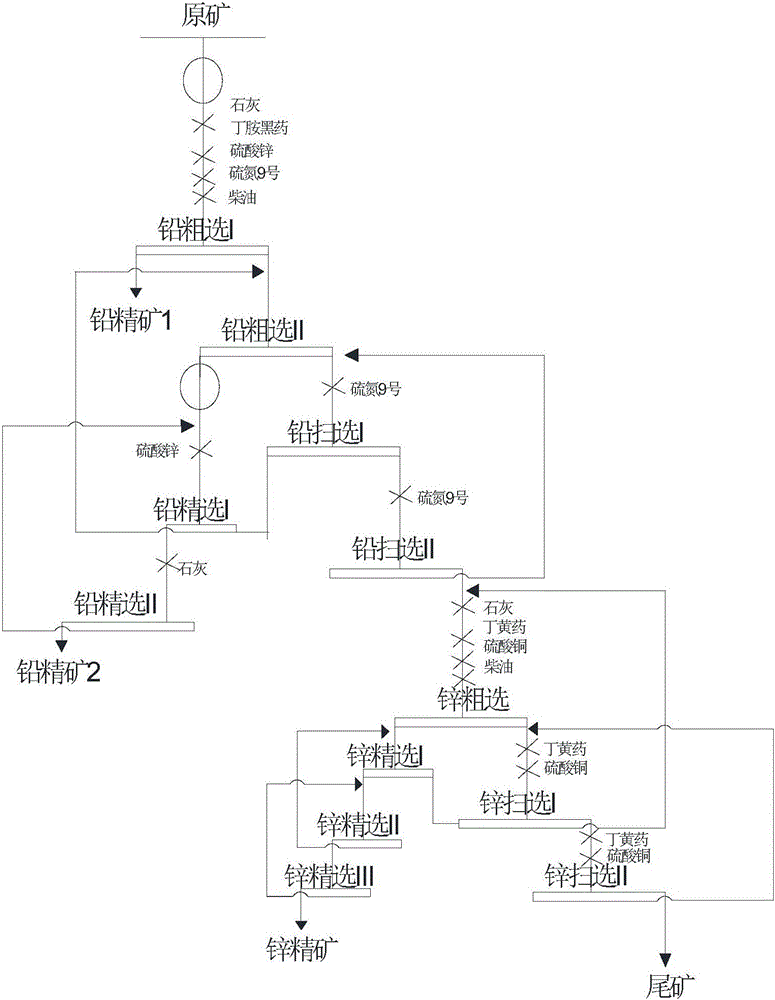

[0055] A kind of beneficiation process of lead-zinc-silver ore provided by the present invention, the grinding fineness of raw ore in ore grinding operation is -200 mesh and accounts for 51%; The step of zinc roughing is carried out on the raw ore after lead roughing, and the step of adding diesel oil is included before zinc roughing.

[0056] (1) For rough lead selection, 1kg / t of lime, 100g / t of zinc sulfate, 2g / t of ammonium butyl ammonium black powder, 50g / t of sulfur nitrogen No. 9, and 50g / t of diesel oil are input per ton of raw ore;

[0057] (2) For zinc roughing, 1kg / t of lime, 100g / t of copper sulfate, 10g / t of butyl xanthate, and 50g / t of diesel oil are input per ton of raw ore.

Embodiment 2

[0059] A kind of beneficiation process of lead-zinc-silver ore provided by the present invention, the grinding fineness of raw ore in ore grinding operation is -200 mesh and accounts for 52%; The step of zinc roughing is carried out on the raw ore after lead roughing, and the step of adding diesel oil is included before zinc roughing.

[0060] (1) For rough lead selection, 5kg / t of lime, 500g / t of zinc sulfate, 10g / t of ammonium butyl ammonium black drug, 200g / t of sulfur nitrogen No. 9, and 200g / t of diesel oil are input per ton of raw ore;

[0061] (2) For zinc roughing, 5kg / t of lime, 500g / t of copper sulfate, 40g / t of butyl xanthate, and 200g / t of diesel oil should be input per ton of raw ore.

Embodiment 3

[0063] A kind of beneficiation process of lead-zinc-silver ore provided by the present invention, the grinding fineness of raw ore in ore grinding operation is -200 mesh and accounts for 53%; The step of zinc roughing is carried out on the raw ore after lead roughing, and the step of adding diesel oil is included before zinc roughing.

[0064] (1) For rough lead selection, 3kg / t of lime, 300g / t of zinc sulfate, 8g / t of butyl ammonium black drug, 100g / t of sulfur nitrogen No. 9, and 100g / t of diesel oil are input per ton of raw ore;

[0065] (2) For zinc roughing, 3kg / t of lime, 300g / t of copper sulfate, 30g / t of butyl xanthate, and 100g / t of diesel oil should be input per ton of raw ore.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com