A labor-saving grinding mechanism and a meat grinder using it

A meat grinder and mincing technology, applied in the field of meat grinders, can solve problems such as laborious mincing, and achieve the effects of labor-saving and easy mincing, easy and fast mincing work, and reduced cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

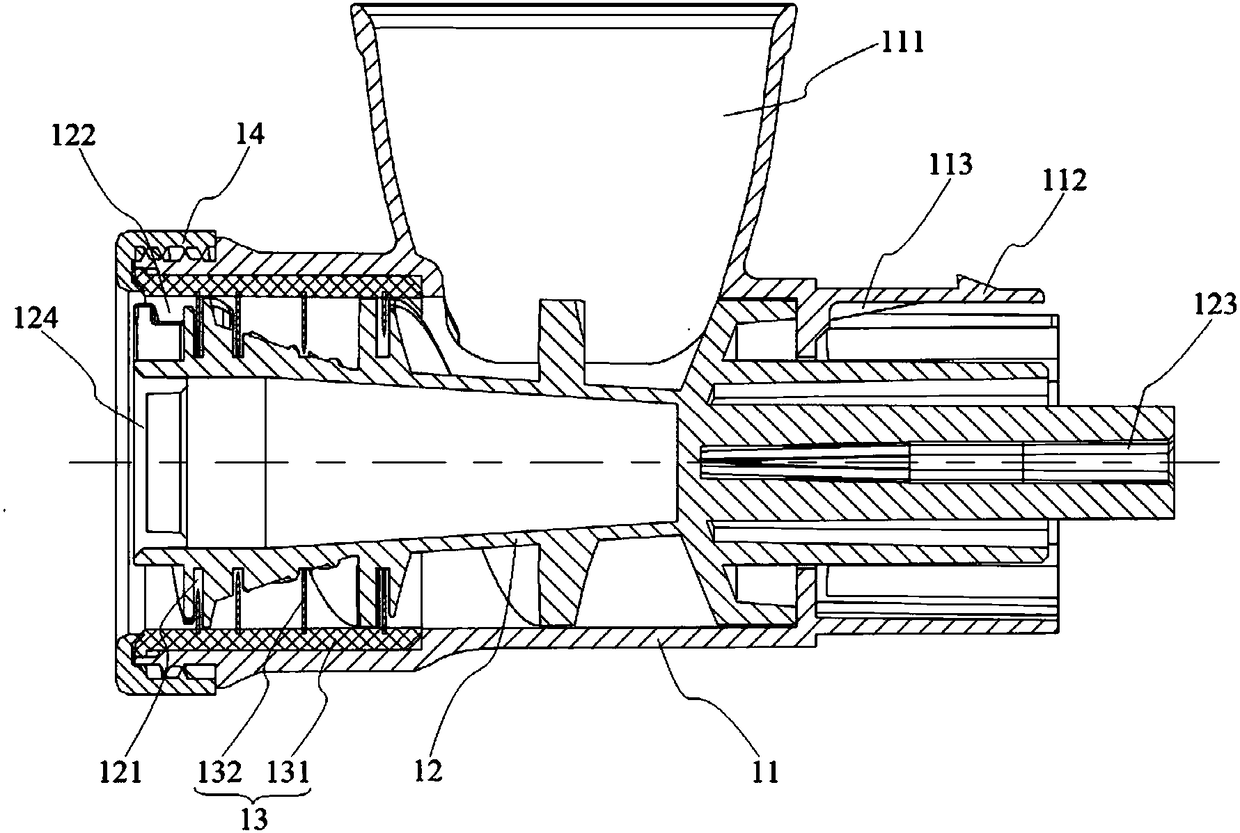

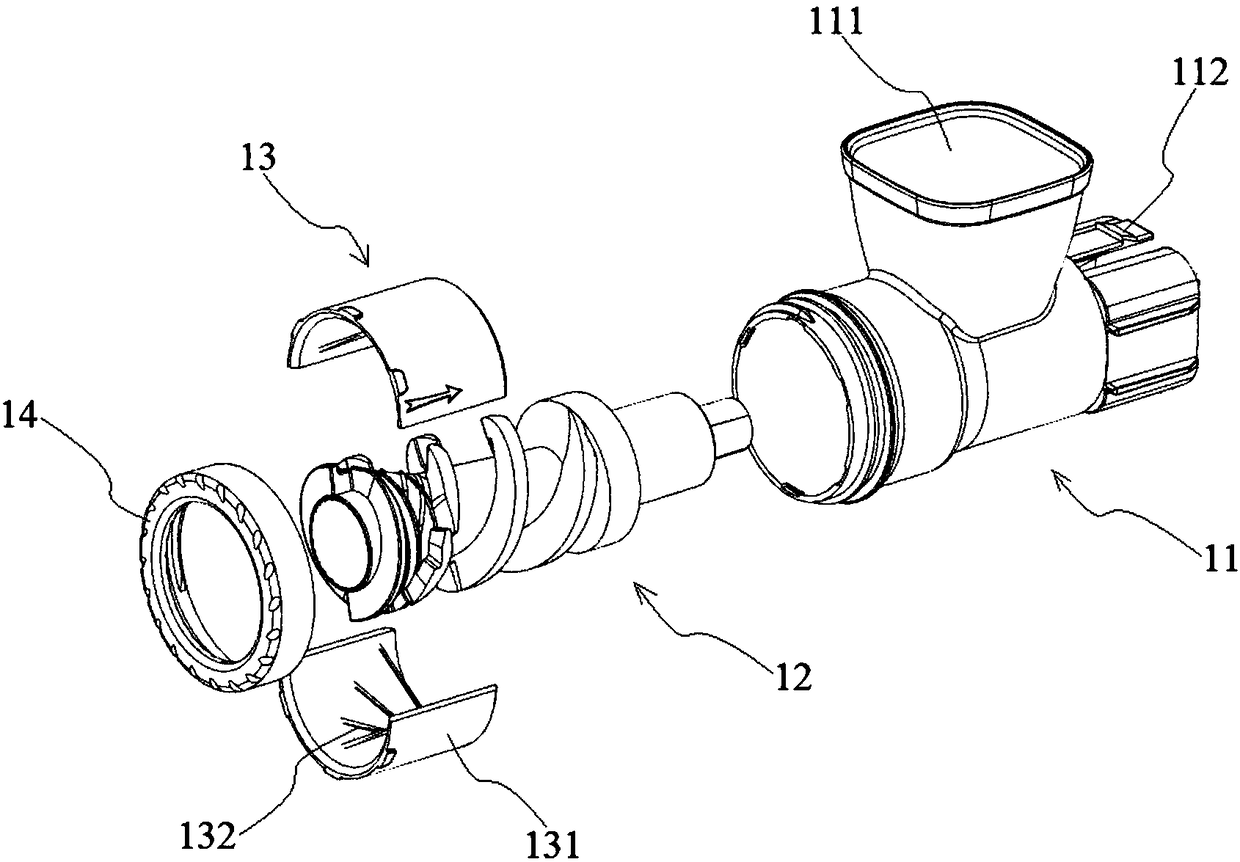

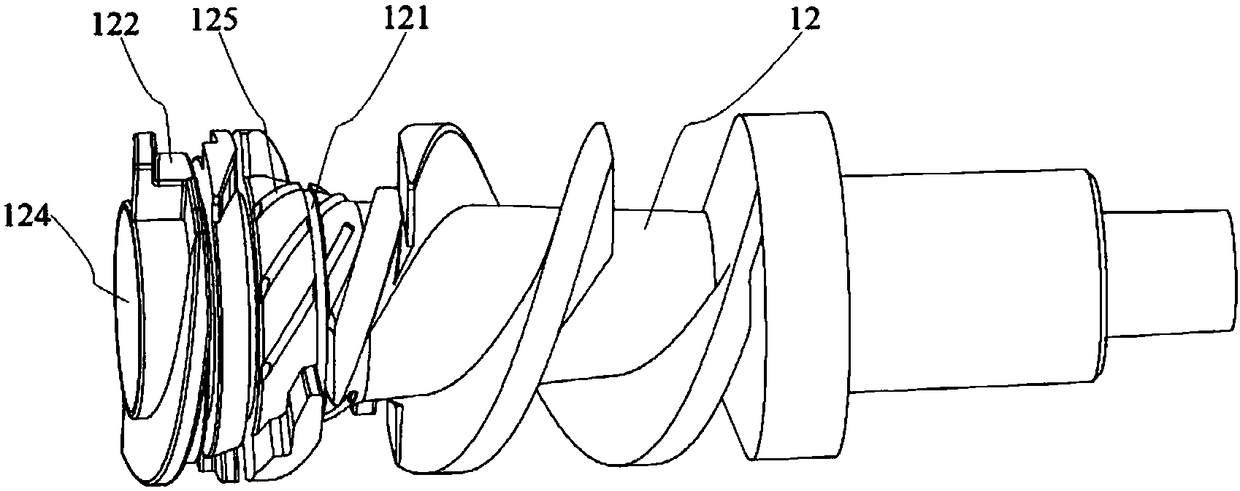

[0044] combine figure 1 and figure 2 As shown, a labor-saving crushing mechanism of this embodiment includes a cylinder body 11 and a screw rod 12 arranged in the cylinder body 11, and also includes two sets of blade sets 13 entangled on the screw rod 12, and the blade groups 13 are positioned on the cylinder body 11 to limit the rotation of the blade set 13, each set of blade sets 13 includes a knife seat 131 and a plurality of blades 132 fixed on the knife seat 131 at intervals. Gradual reduction is better, and the object to be chopped can be chopped gradually. Each blade 132 is perpendicular to the axial direction of the screw 12 and cooperates with the knife groove 121 provided on the screw 12 . A labor-saving shredding mechanism of this embodiment utilizes two groups of blade groups 13 to be entwined on the screw rod 12, so that the blades 132 are at least distributed on both sides of the screw rod 12, so that the uniform shredding of the shredded material is realized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com