Aluminum alloy sectional material and combined cabinet body

A technology of aluminum alloy profiles and combined cabinets, which is applied in the field of furniture, can solve the problems of easy aging, moisture cracking, etc., and achieve the effect of not easy to loosen, increase strength, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

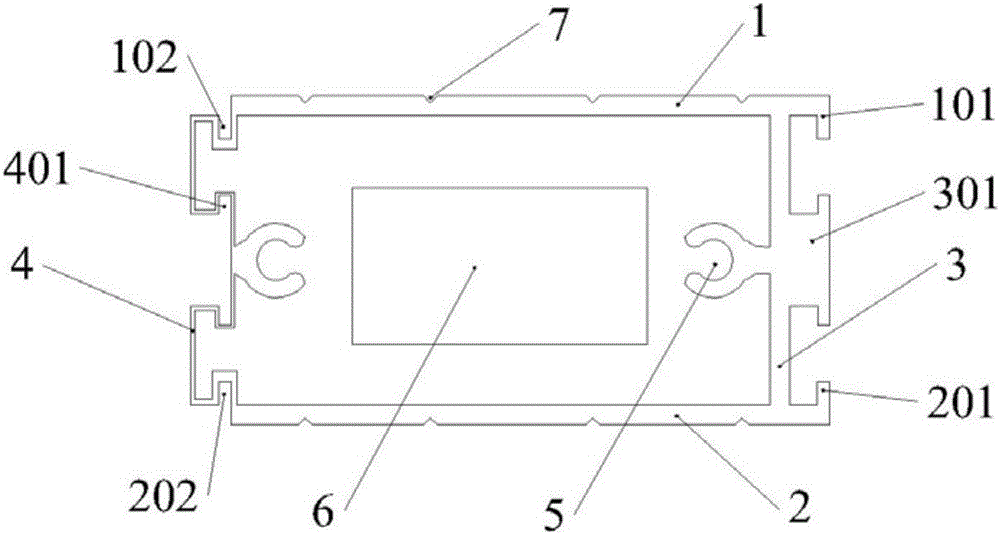

[0053] Such as figure 1 As shown, the present invention provides an aluminum alloy profile, comprising an upper panel 1, a lower panel 2, a first side panel 3 and a second side panel 4, the upper panel 1 and the lower panel 2 are arranged in parallel, and the upper panel 1 and the lower panel 2 connected through the first side plate 3 and the second side plate 4;

[0054] One side of the upper panel 1 is provided with a first socket 101, and the opposite side is provided with a first socket 102 matching with the first socket 101;

[0055] One side of the lower panel 2 is provided with a second socket 201 , and the opposite side is provided with a second socket 202 matched with the second socket 201 .

[0056] In this embodiment, further, as figure 1 As shown, the first socket 101 and the second socket 201 are arranged in a rectangular shape, the first socket 101 and the first socket 102 are perpendicular to the upper panel 1, the second socket 201 and the second The inserti...

Embodiment 2

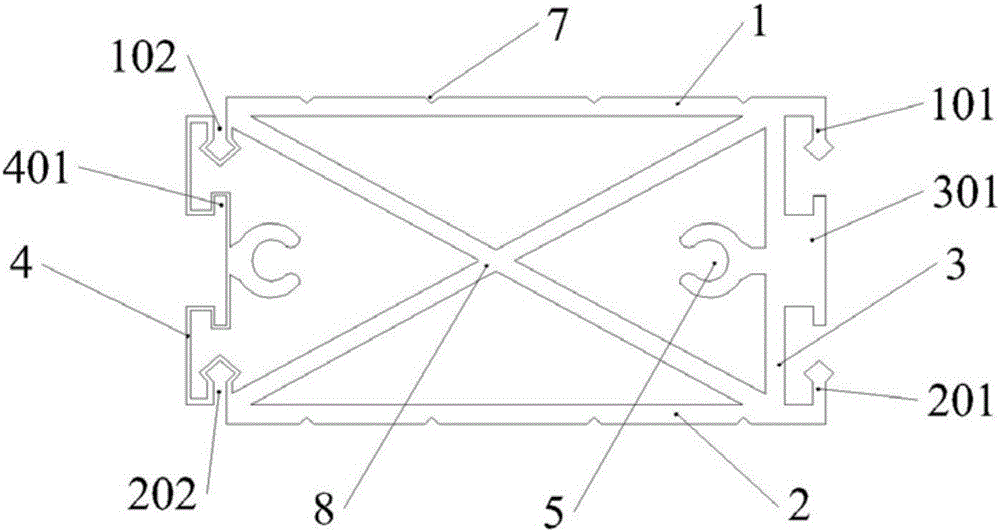

[0059] Different from Embodiment 1, in this embodiment, further, as figure 2 As shown, the first socket 101 and the second socket 201 are arranged in a rectangular shape, the first socket 101 and the first socket 102 are perpendicular to the upper panel 1, the second socket 201 and the second The socket slots 202 are all perpendicular to the lower panel 2; the tail ends of the first plug connector 101, the second plug connector 201, the first plug slot 102 and the second plug slot 202 are all set in a rhombus shape. Compared with Embodiment 1, the first plug connector 101 and the first plug slot 102 with a diamond-shaped tail end are less likely to loosen after being assembled, and the structure is more stable.

[0060] Different from Embodiment 1, in this embodiment, further, as figure 2 As shown, an X-shaped reinforcement 8 is arranged between the upper panel 1 and the lower panel 2 . The X-shaped reinforcement 8 plays the same role as the load-bearing chamber 6 in Embod...

Embodiment 3

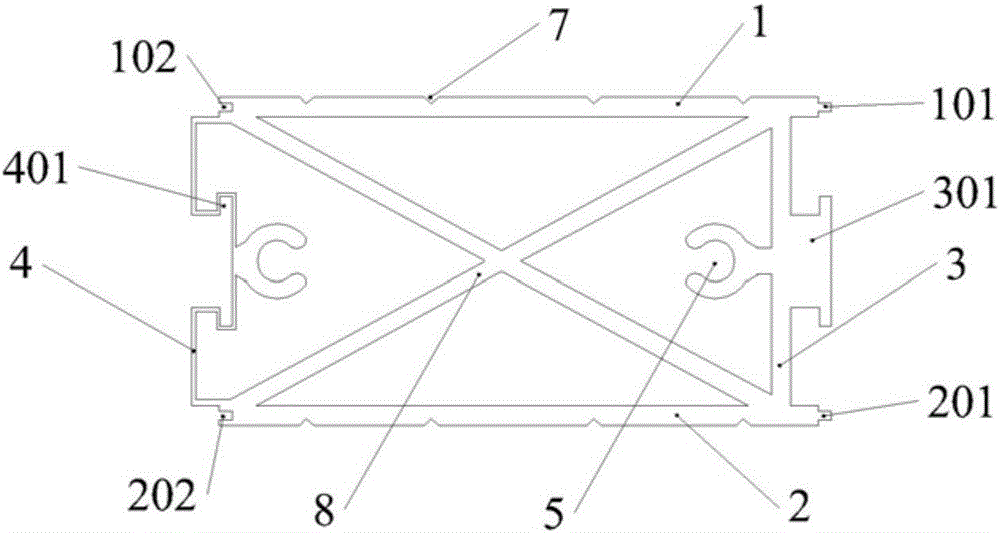

[0062] Different from Embodiment 1, in this embodiment, further, as image 3 As shown, the first socket 101 and the second socket 201 are arranged in a rectangular shape, the first socket 101 and the first socket 102 are parallel to the upper panel 1, the second socket 201 and the second The socket slots 202 are all parallel to the lower panel 2, the surfaces of the first plug connector 101 and the second plug connector 201 are provided with helical teeth, and the first plug slot 102 and the second plug slot 202 are both provided with occlusal teeth. The above-mentioned helical teeth and the above-mentioned occlusal teeth can engage and fix each other. When the first socket 101 and the first socket 102 are parallel to the upper panel 1, and the second socket 201 and the second socket 202 are parallel to the lower panel 2, the above two aluminum alloy profiles are combined It is very convenient, but it is obvious that the above two aluminum alloy profiles will be separated if ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com