Sampling device and sampling method for accurate determination of coal seam gas content

A technology for accurate measurement of coal seam gas, which is applied to the sampling device and sampling field for accurately measuring coal seam gas content, can solve the problems of poor accuracy, difficulty in measurement, and error of underground gas content, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

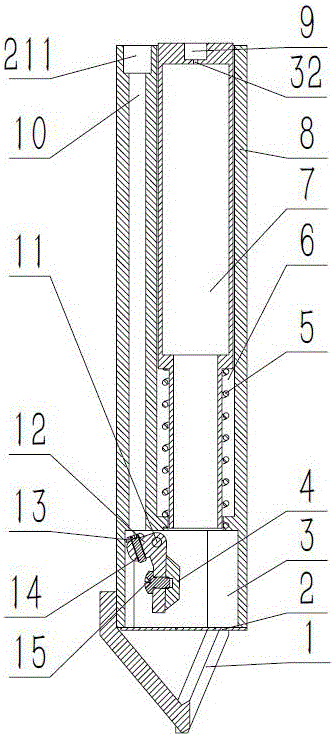

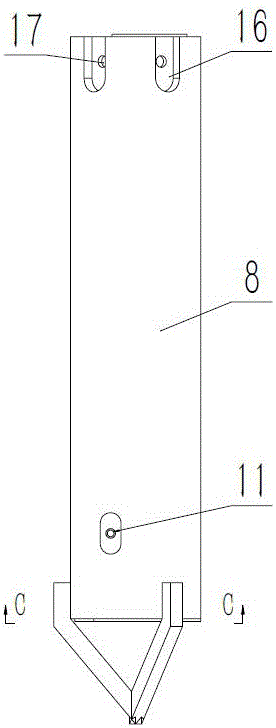

[0027] see Figure 1-8 , a sampling device for accurately measuring the gas content of coal seams, which includes a hollow drill rod, and is characterized in that: after the hollow drill rod is fixed through a connecting plate placed in a connecting groove 16 and a high-energy power rod 18 is fixed by a threaded hole 17 of the connecting groove, and then placed The connection plate in the connection groove 16 fixes the sampling drill bit by the connection groove threaded hole 17.

no. 2 example

[0029] see Figure 1-8 , a sampling device for accurately measuring the gas content of coal seams, which includes a hollow drill rod, and is characterized in that: after the hollow drill rod is fixed through a connecting plate placed in a connecting groove 16 and a high-energy power rod 18 is fixed by a threaded hole 17 of the connecting groove, and then placed The connection plate in the connection groove 16 fixes the sampling drill bit by the connection groove threaded hole 17.

[0030]Among them: the sampling drill bit, including the impact air channel 10 with the impact air channel slot 211 in the sampling bit shell 8, the gas desorption port 9 and the gas desorption hole 32 with the gas desorption port plug, in the coal sample tank movement chamber 6 The coal sample tank 7 composed of the inner spring 5, the impact gas passage 10 and the coal charging cavity 3 at the front end of the coal sample tank 7 are fixed on the sampling drill shell 8 by the rotary gland shaft 11 a...

no. 3 example

[0032] see Figure 1-8 , a sampling device for accurately measuring the gas content of coal seams, which includes a hollow drill rod, and is characterized in that: after the hollow drill rod is fixed through a connecting plate placed in a connecting groove 16 and a high-energy power rod 18 is fixed by a threaded hole 17 of the connecting groove, and then placed The connection plate in the connection groove 16 fixes the sampling drill bit by the connection groove threaded hole 17.

[0033] Among them: the sampling drill bit, including the impact air channel 10 with the impact air channel slot 211 in the sampling bit shell 8, the gas desorption port 9 and the gas desorption hole 32 with the gas desorption port plug, in the coal sample tank movement chamber 6 The coal sample tank 7 composed of the inner spring 5, the impact gas passage 10 and the coal charging cavity 3 at the front end of the coal sample tank 7 are fixed on the sampling drill shell 8 by the rotary gland shaft 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com