Composite film and preparation method thereof

A composite film and thin film technology, applied in the field of materials, can solve the problems of excessive packaging of laser film, intensification of unfair competition, rainbow changes, visual impact, decorative performance, visual fatigue of ordinary consumers, etc., and achieve novel and unique effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

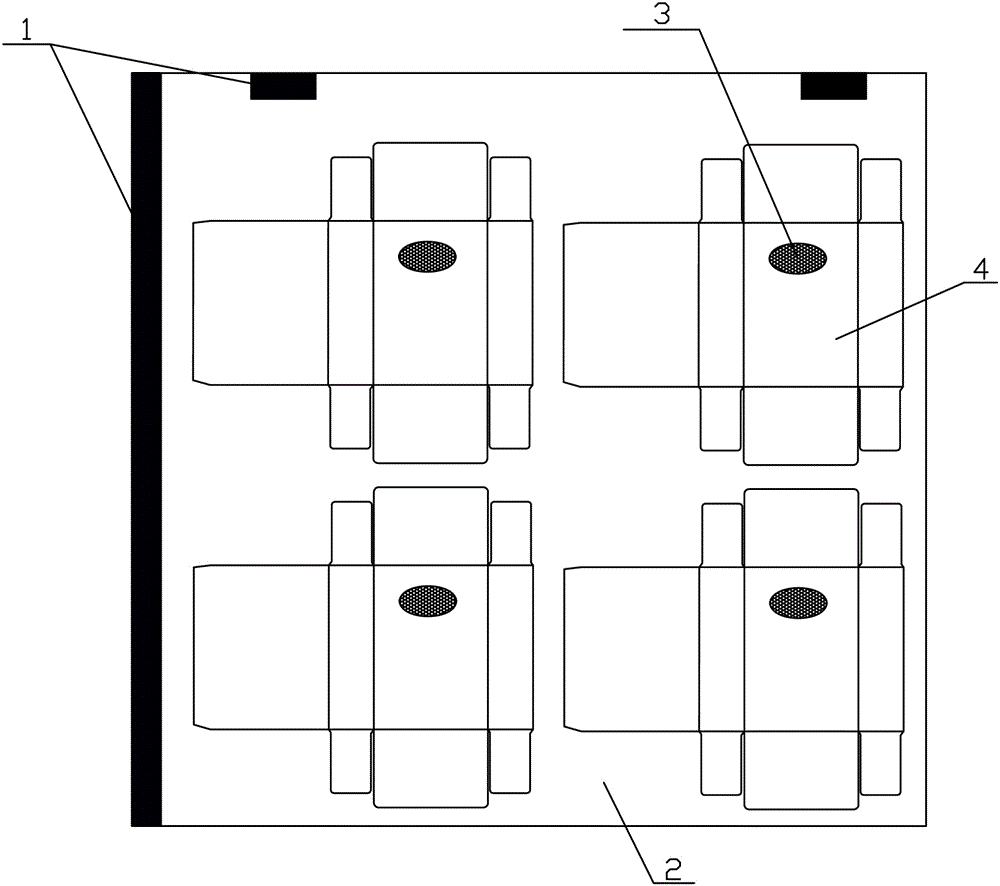

[0037] A composite membrane, (such as figure 1 shown), including a substrate layer 2, the upper surface of the substrate layer 2 includes a microlens grating layer 3, a laser holographic layer 4; a metal reflective layer 6, a composite glue layer 7 and a paper layer are sequentially arranged on the lower surface of the substrate layer 2 The base layer 8 corresponds to the position of the microlens grating layer 3 , and the microtexture layer 5 is arranged between the lower surface of the substrate layer 2 and the metal reflective layer 6 . The substrate layer 2 and the microlens grating layer 3 form an imaging unit, and the focal length of the imaging unit falls on the micro-texture layer 5 on the lower surface of the substrate layer. The arrangement of the micro-lens grating layer 3 and the micro-texture layer 5 has an included angle, and in order to achieve a three-dimensional imaging effect, the included angle ranges from 0° to 5°. The thickness of the substrate layer 2 is...

Embodiment 2

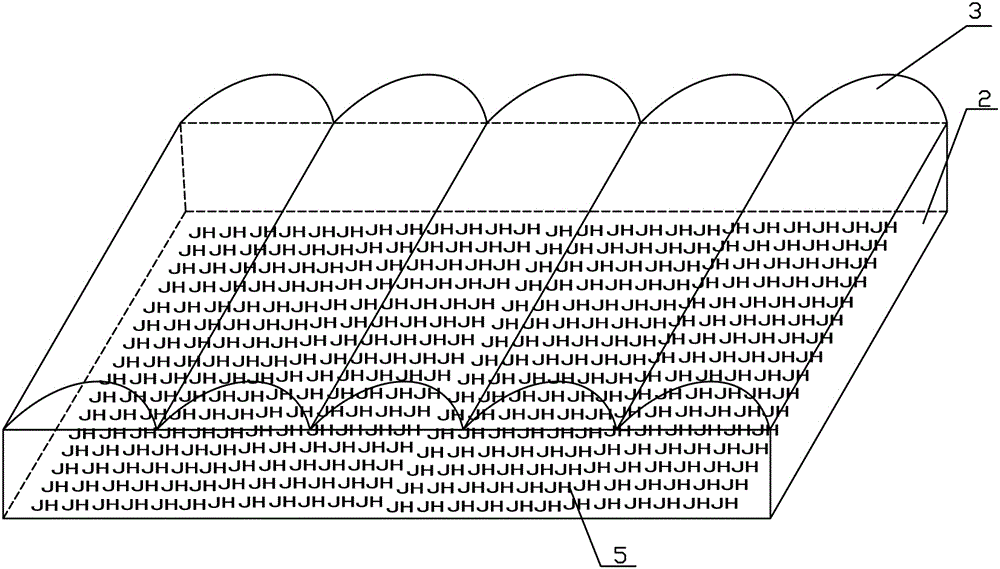

[0045] Such as image 3 As shown, others are as described in Embodiment 1, except that the microlens grating layer 3 is a one-dimensional lenticular lens grating, the height of the lenticular lens grating is 18um, and the thickness of the substrate layer 2 is 50um. The JH three-dimensional movement direction of the micro-graphic layer 5 is horizontal movement (that is, its movement direction is perpendicular to the direction of the lenticular grating stripes). The lower surface 22 of the substrate layer is first coated with a color layer, and its hue is golden. Then process the micro-graphic layer 5 on the color layer. The effect is that the JH three-dimensional dynamics of the micro-graphic layer 5 presents deep (golden) color shading.

Embodiment 3

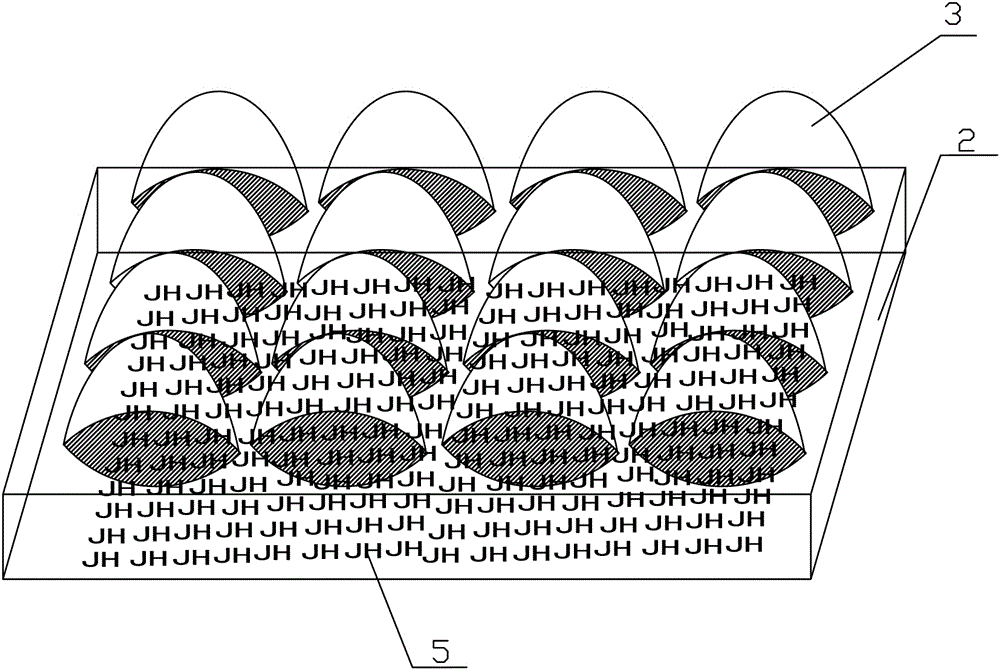

[0047] Such as Figure 4 As described above, others are as described in Embodiment 1, the difference is that the microlens grating layer 3 is a two-dimensional microlens grating (the two-dimensional grating microlens array arrangement includes circular, rectangular or regular hexagonal, etc.), preferably Two-dimensional dot microlenses (such as Figure 5 shown). The microlens height h is 10um. By changing the arrangement of the micro-text 5 , the micro-text can visually present various three-dimensional dynamics. The metal reflective layer 6 is an aluminized layer, and the thickness of the aluminized layer 6 is 380-500Å.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com