Ultrasonic fatigue testing method of cylindrical sample with uniform cross sections

A fatigue test, cylindrical technology, used in the analysis of solids, instruments, and materials using sonic/ultrasonic/infrasonic waves, which can solve the problems of unstable test, difficult to complete mechanical processing, deviation between actual vibration displacement value and theoretical value, etc. Achieve the effect of saving test cost, accelerating fatigue test, and small processing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

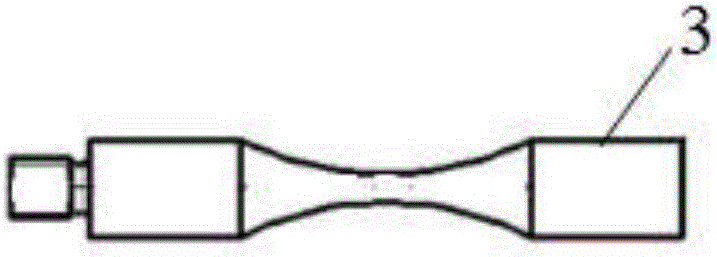

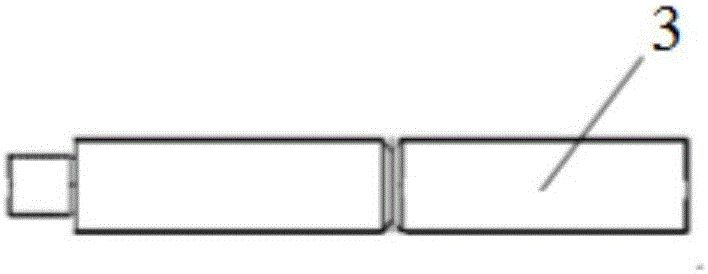

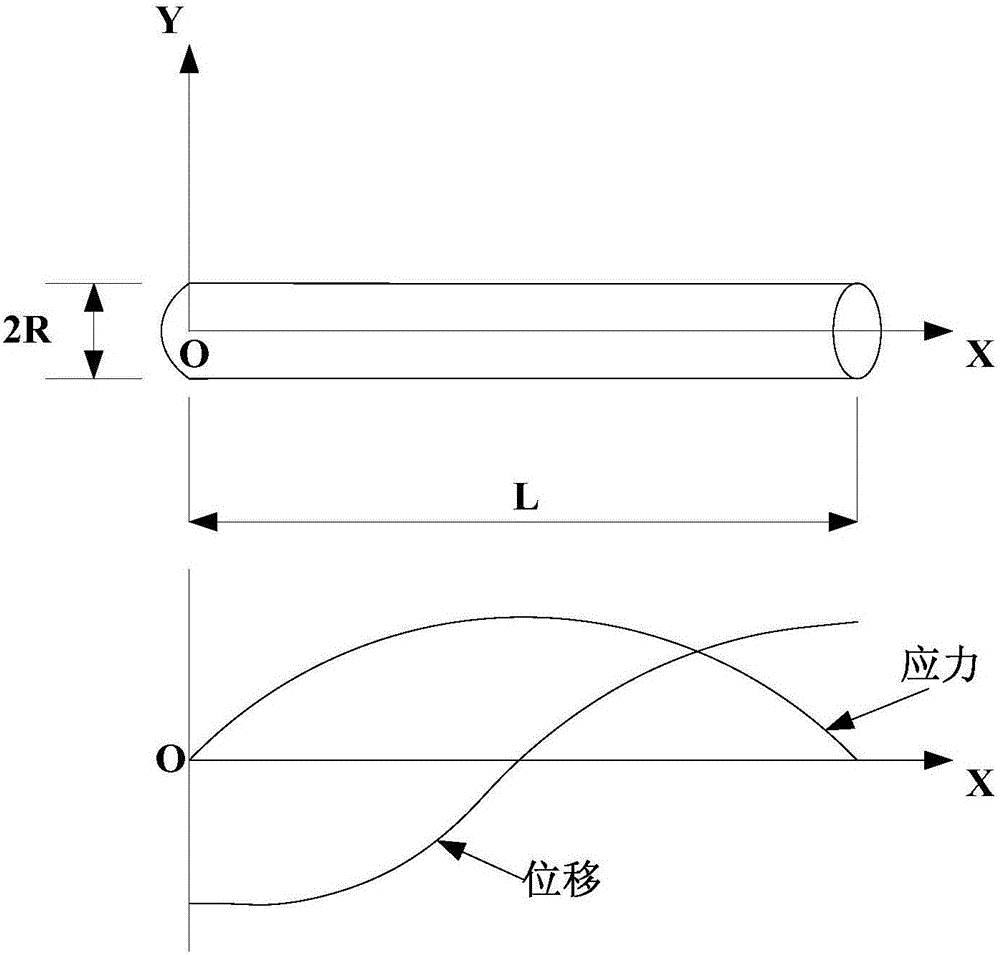

[0051] Such as Figure 1~2 Shown is a schematic diagram of the structure of the cylindrical specimen with transition arc and the cylindrical specimen with notch used in the conventional ultrasonic fatigue test method.

[0052] Such as Figure 5As shown, it is the USF-2000 ultrasonic fatigue testing machine produced by Shimadzu Corporation of Japan, and its resonance frequency is 20KHz. The ultrasonic fatigue testing machine is mainly composed of a transducer 1 , a displacement amplifier 2 , a cooling air nozzle 4 , an ultrasonic generator 5 and a system control software 6 . Wherein, the ultrasonic generator 5 converts the electrical signal of 50 Hz into an ultrasonic sine wave electrical signal of 20 KHz, and changes the amplitude of the sine wave by adjusting the voltage; the transducer 1 converts the electrical signal provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com