Rivet plug sealing performance detection base

A technology of sealing detection and base, applied in the direction of liquid/vacuum measurement of liquid tightness, etc., can solve the problems of safe process hole leakage, riveting plug falling off, hidden dangers, etc., and achieves high degree of precise control and reduced power consumption. Small, fast temperature change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

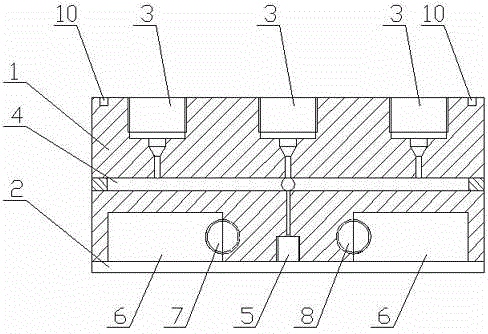

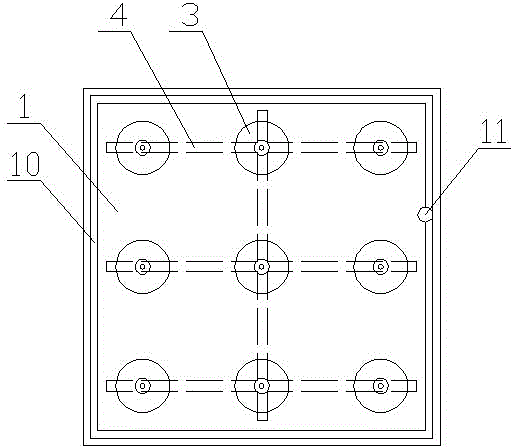

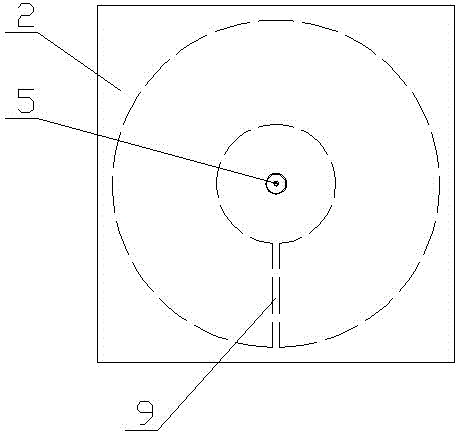

[0014] Depend on figure 1 , figure 2 and image 3 As shown, the rivet tightness detection base is composed of a main body 1 and a bottom plate 2. The main body 1 is in the shape of a plate as a whole. On the upper surface of the main body 1, there are a plurality of threaded hole seats 3 arranged in a matrix. Each The bottoms of the threaded sockets 3 communicate with each other through the channel 4 provided inside the main body 1, and an oil filling port 5 is opened at the center of the bottom of the main body 1, and the oil filling port 5 communicates with the channel 4 inside the main body 1. The oil injection port 5 injects a certain pressure of hydraulic oil into each threaded hole seat 3, and the bottom of the main body 1 is also provided with an annular temperature control groove 6 and an oil inlet 7 and an oil outlet connected to the annular temperature control groove 6. 8, the bottom plate 2 is fixedly welded on the bottom of the main body 1 to seal the annular te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com