Cylinder head assembly

A cylinder head and component technology, applied in the field of component temperature, can solve the problems of small temperature measurement range, uncertainty of operating temperature, and high technical complexity of temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

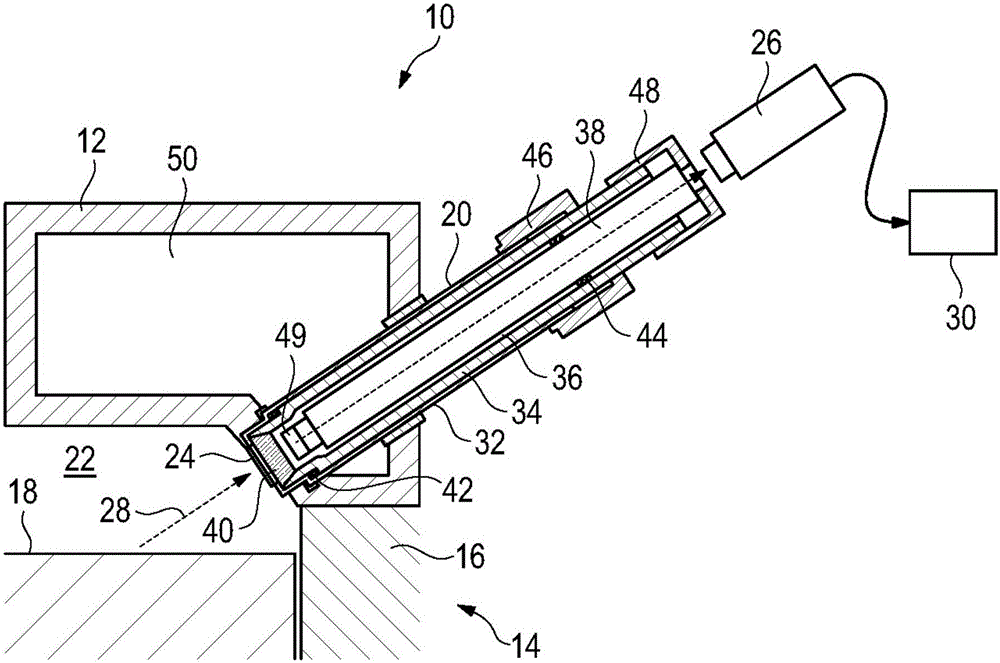

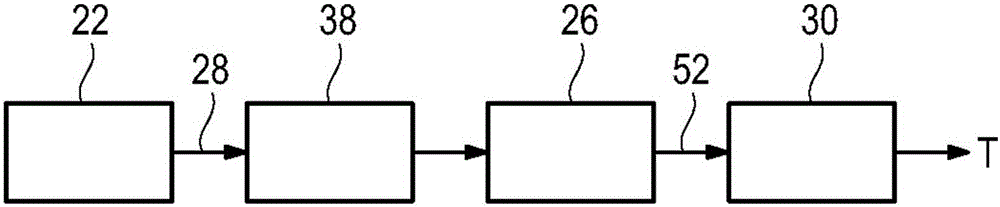

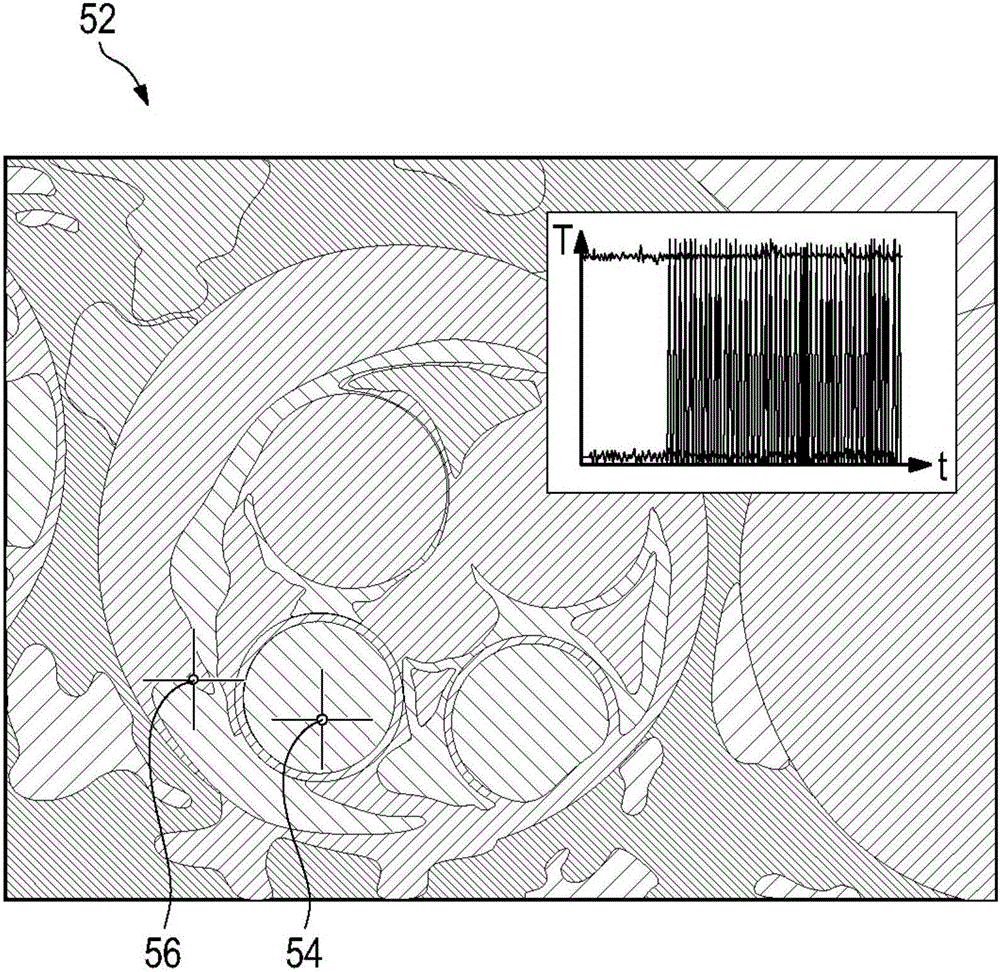

[0042] figure 1 A schematic partial view of the cylinder head assembly is shown, generally designated 10 . The cylinder head assembly 10 generally has a housing 12 that defines the cylinder head assembly 10 on the outside. The cylinder head assembly 10 is connected to the figure 1 The engine block 14 , which is only schematically shown in a partial view in , has at least one cylinder 16 in which at least one piston 18 is accommodated. As a result of the high power densities of modern internal combustion engines, the thermal load, especially of the piston 18, is very high, with the result that the actual operating temperature of the piston and its surfaces has to be measured frequently during the development phase in order to avoid the operation of the final product During excessive heat load.

[0043] exist figure 1 The cylinder head assembly also has optical passages 20 formed in the housing 12 and having openings 24 assigned to the combustion chambers 22 of the engine bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com