W-shaped flame direct-current burner pulverized coal composite furnace with fluidized bed

A fluidized bed and burner technology, which is applied to fluidized bed combustion equipment, uses a variety of fuels, and burns fuel in a molten state, etc., can solve the problem of single fuel, high fly ash content, nitrogen oxides, sulfur dioxide emissions. It can reduce the cost of desulfurization, inhibit the formation of nitrogen oxides, and reduce the overall temperature level of the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

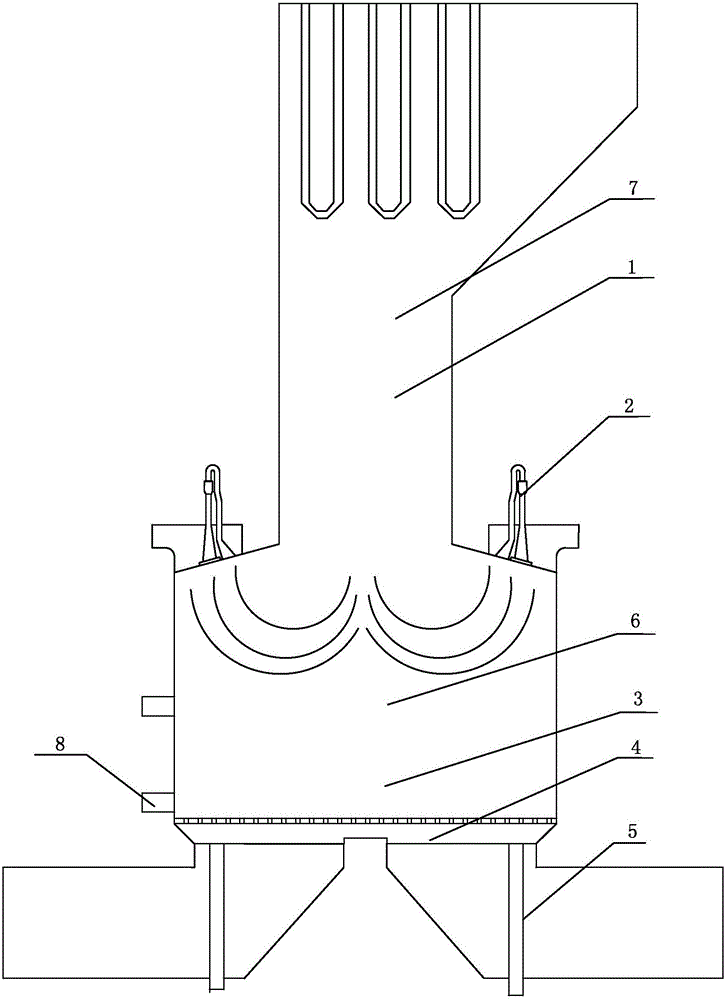

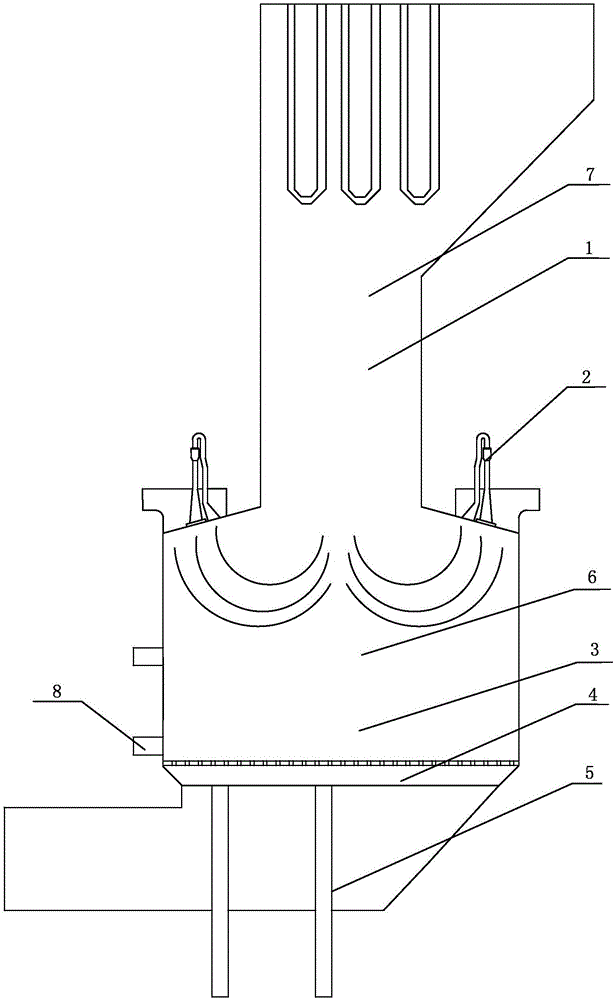

[0013] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a W-type flame direct-flow burner pulverized-coal composite furnace with a fluidized bed described in this embodiment, it includes a furnace body 7, at least one fluidized bed 4, a slagging pipe 5 and a plurality of direct current The primary air duct 2 of the burner, the fluidized bed 4 is installed at the bottom of the furnace body 7, the air distribution plate is installed on the fluidized bed 4, and the primary air duct 2 of multiple DC burners are all installed on the furnace arch of the furnace body 7 , the area located in the furnace body 7 close to the top of the furnace body 7 is the upper furnace, and the area located in the furnace body 7 near the upper part of the fluidized bed 4 is the dense-phase zone combustion chamber 3, which is located between the upper furnace 1 and the dense-phase zone combustion chamber 3 The area is the combustion chamber 6 of the pulverized coal...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination Figure 1-Figure 3 Illustrate this embodiment, a W-type flame once-through burner pulverized-coal composite furnace with a fluidized bed described in this embodiment, the number of the fluidized bed 4 is one or two, and the W-type swirling coal The pulverized boiler is combined with the fluidized bed, and the fluidized bed 4 and the air distribution plate on the fluidized bed 4 are arranged under the compound furnace. The coal in the fluidized bed 4 is fluidized on the air distribution plate. When there are two fluidized beds, the air enters from both sides below the furnace body 7, and when the lower hearth of the composite furnace is connected with a fluidized bed 4, the air enters from one side below the furnace body 7. Other structures and functions are the same as those in Embodiment 1.

specific Embodiment approach 3

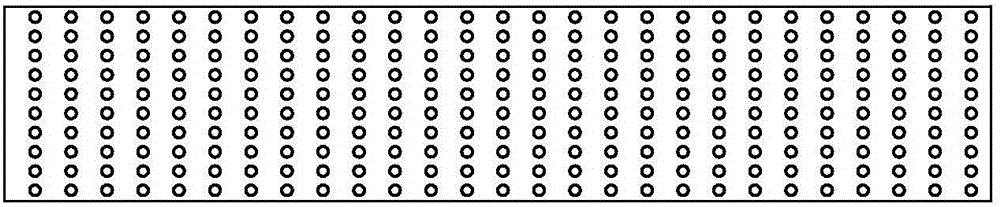

[0015] Specific implementation mode three: combination image 3 Describe this embodiment, a W-type flame direct-flow burner pulverized coal composite furnace with a fluidized bed described in this embodiment, the air distribution plate of the fluidized bed is uniformly processed with a plurality of through holes, other structures and The effect is the same as that in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com