Hydraulic control system of rudder blade platform

A hydraulic control system and platform technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, ship construction, etc., can solve problems that are difficult to meet the requirements of rudder blade installation accuracy and technological level, without involving the hydraulic system, labor intensity High-level problems, to avoid impact, facilitate inspection and maintenance, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

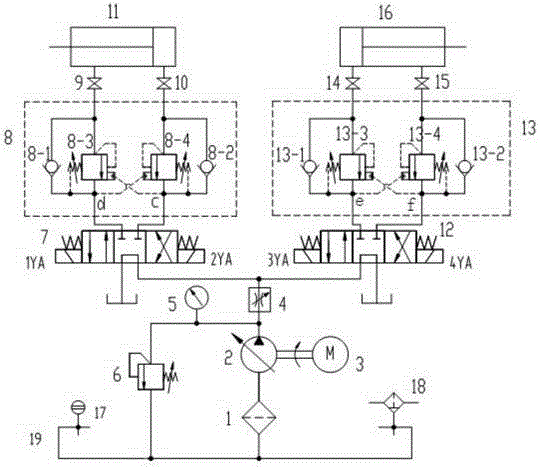

[0018] Such as figure 1 As shown, a hydraulic control system for the rudder blade platform includes a fuel tank 19, a variable pump 2, a motor 3, a speed control valve 4, a pressure gauge 5, an overflow valve 6, a three-position four-way electromagnetic reversing valve A7, three-position four-way Through the electromagnetic reversing valve B12, the first two-way balance valve 8, the second two-way balance valve 13, the first hydraulic cylinder 11 and the second hydraulic cylinder 16; the motor 3 and the variable displacement pump 2 drive the variable displacement pump 2 through the coupling Work; the oil inlet of the variable pump 2 is connected to the fuel tank 19, and a coarse filter 1 is also arranged between the fuel tank 19 and the variable pump 2;

[0019] The oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com