Fabricated steel frame and steel plate shear wall structure replaceable after earthquake

A steel plate shear wall and steel frame technology, applied in the direction of walls, building components, building structures, etc., can solve economic losses, cannot meet the rapid repair of lifeline projects, beam end nodes, embedded steel plates and connectors cannot be replaced to reduce economic losses, increase the speed of structural construction, and reduce repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

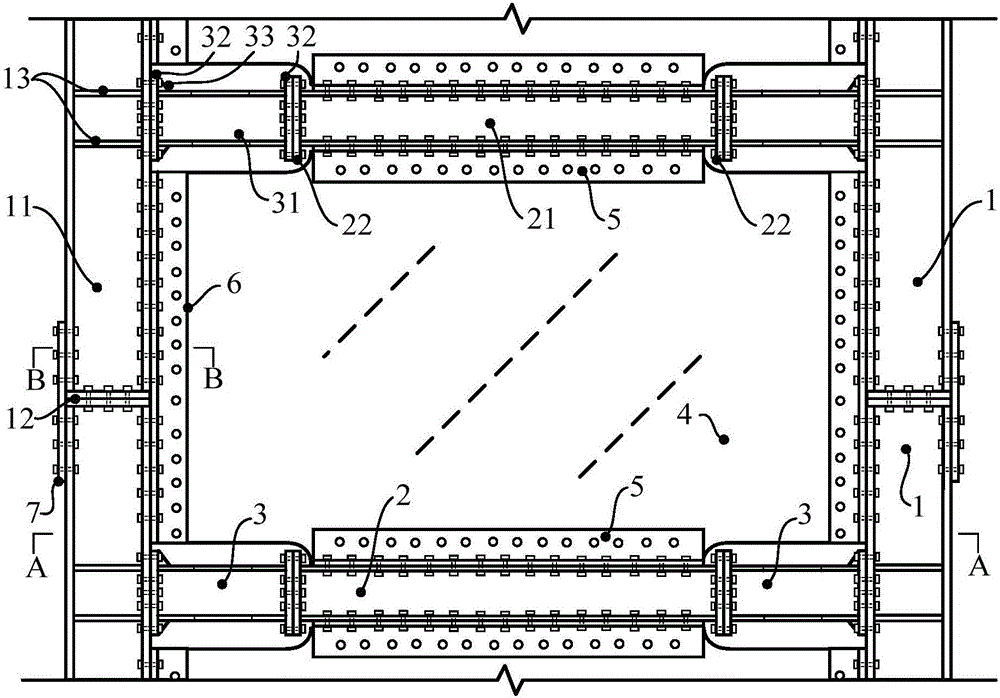

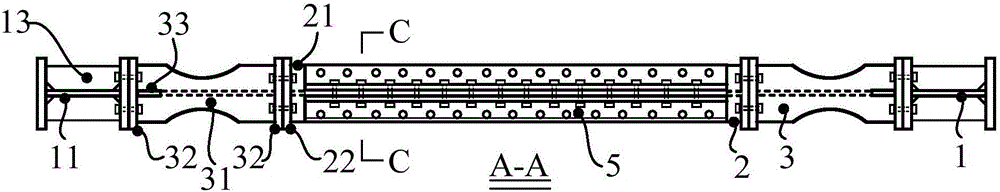

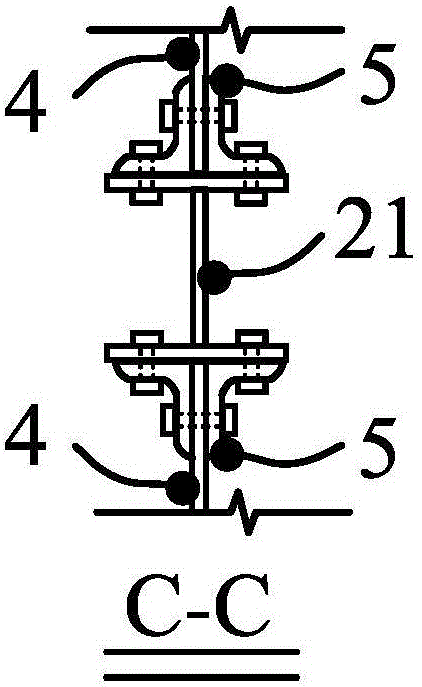

[0041] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0042] like Figure 1-Figure 17 As shown, a post-earthquake replaceable assembled steel frame and steel plate shear wall structure includes frame steel columns 1, main steel beams 2, post-earthquake replaceable energy-consuming nodes 3 and post-earthquake replaceable embedded steel plates 4.

[0043]The frame steel column 1 includes a column body 11 , a first end plate 12 , a cover plate 7 and a column angle steel 6 , and the node domain stiffeners 13 are fixed on the column body 11 . The web of the column 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com