Non-dismantling prefabricated concrete pile protecting die plate and construction method

A technology of prefabricated concrete and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of shortened construction period, water seepage around the pile foundation, high construction cost, etc., and achieve shortened construction period, high construction safety, The effect of construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

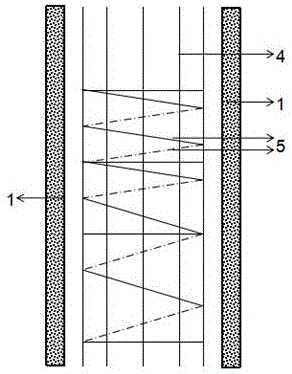

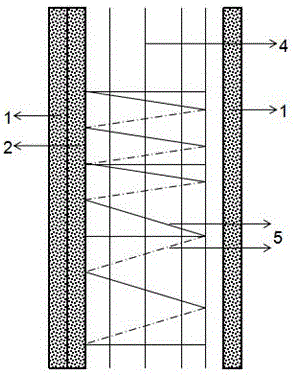

[0051] Such as Figure 1 to Figure 4 As shown, a precast concrete pile protection formwork without demolition includes a precast concrete protective layer 1 with a circular cross section and a plurality of concave arc-shaped concrete protruding blocks 2, and a plurality of concave arc-shaped concrete protruding blocks 2 are protected along the precast concrete The inner circumferential surface of layer 1 is symmetrically arranged at intervals, and is prefabricated with the precast concrete protective layer 1 at one time. The long hole 3 is provided with a reinforcement cage at the inner peripheral surface formed by a plurality of concave arc-shaped concrete protruding blocks 2 .

[0052] The reinforcement cage is composed of a plurality of main reinforcements 4 arranged at intervals and spiral stirrups 5 wound on the plurality of main reinforcements 4 .

[0053] When used for manual hole-digging piles, the through-long hole 3 can be used as a ventilation air supply port and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com