Deep-water construction method of bridge at water pebble soil and argillaceous sandstone areas and auxiliary working platform

A kind of argillaceous sandstone, construction method technology, applied in bridges, water conservancy projects, bridge construction and other directions, can solve the problems of long construction time, difficult foundation construction of large bridges, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

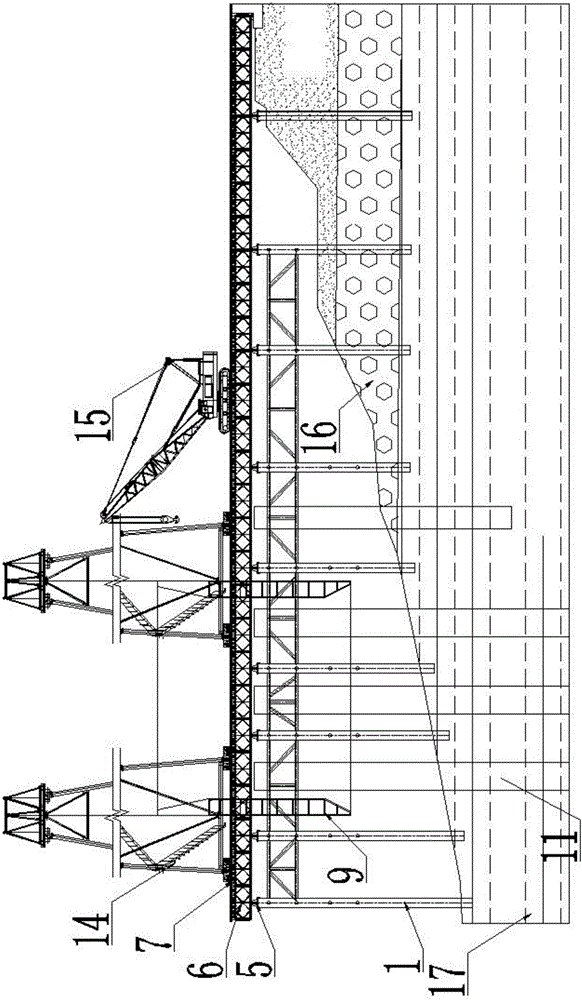

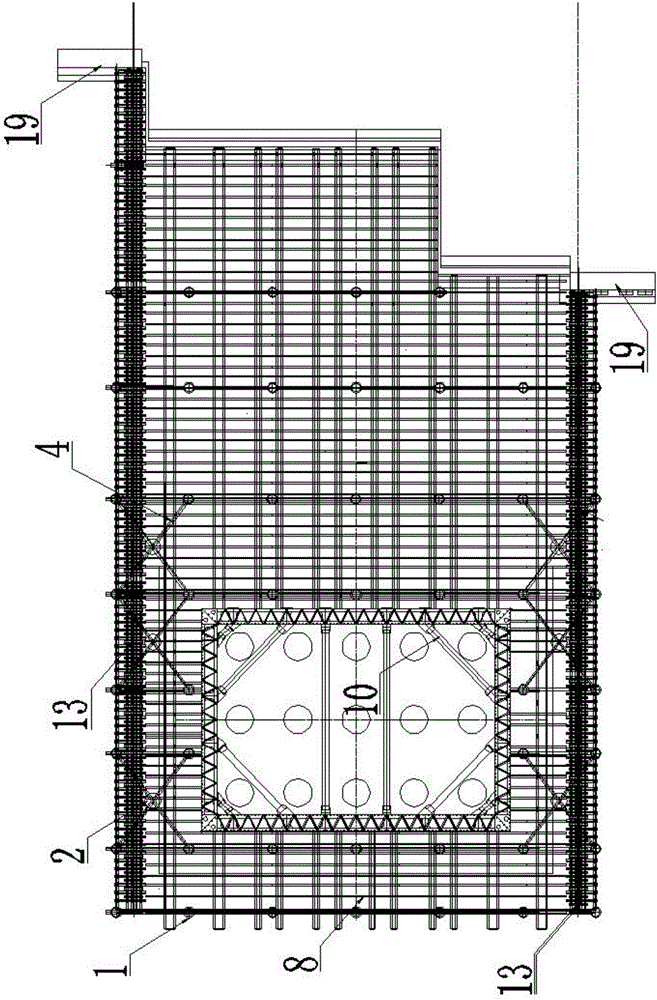

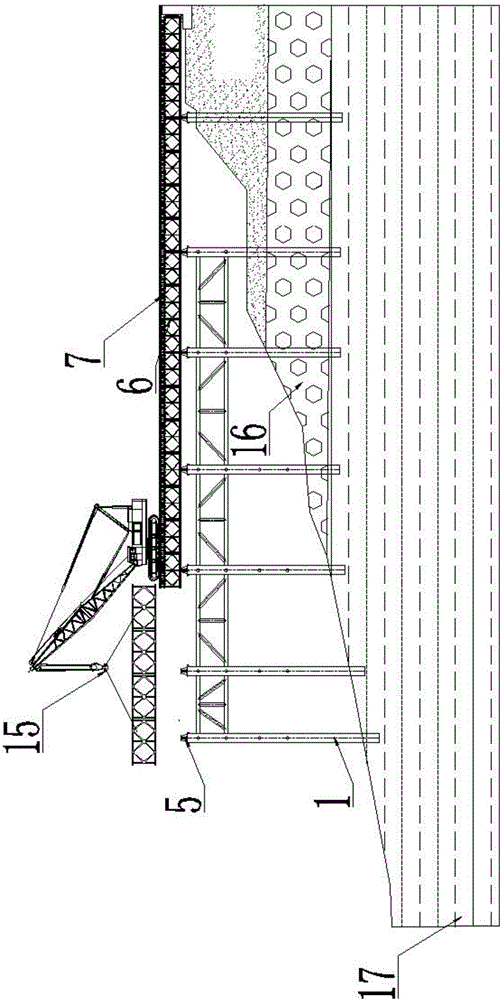

[0035] 1-steel pipe pile, 2-anchor pile, 3-steel pipe pile connection system, 4-anchor pile connection system, 5-pile top distribution beam, 6-main longitudinal beam, 7-platform deck beam, 8-platform Panel, 9-Steel cofferdam, 10-Steel casing, 11-Pile foundation, 12-Cap, 13-Gantry crane track, 14-Gantry crane, 15-Crawler crane, 16-Pebble soil, 17-Argillaceous sandstone, 18 - drilling rig, 19 - abutment, 20 - connection system between steel pipe piles and steel casing

[0036] A deep water construction method for bridges in pebble soil and argillaceous sandstone areas, comprising the steps of:

[0037] (1) Part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com