Bridge integrally-assembled pier and construction method

A prefabricated and integrated technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of complicated processes, insufficient seismic performance, economic disadvantages, etc., to simplify the connection process, facilitate energy saving, material reduction and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The essence of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation, but the content of the present invention is not limited thereto.

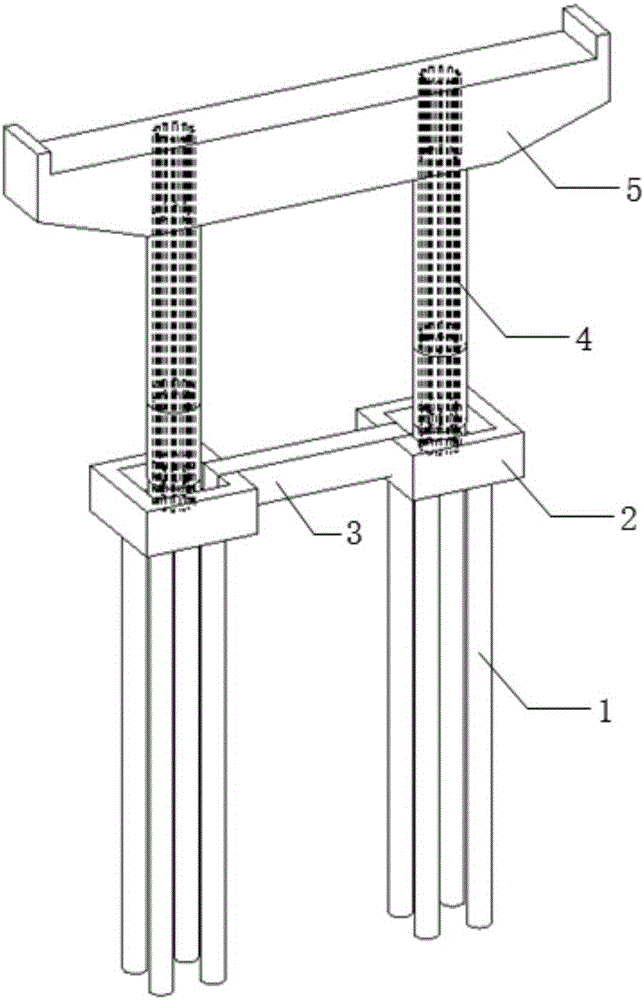

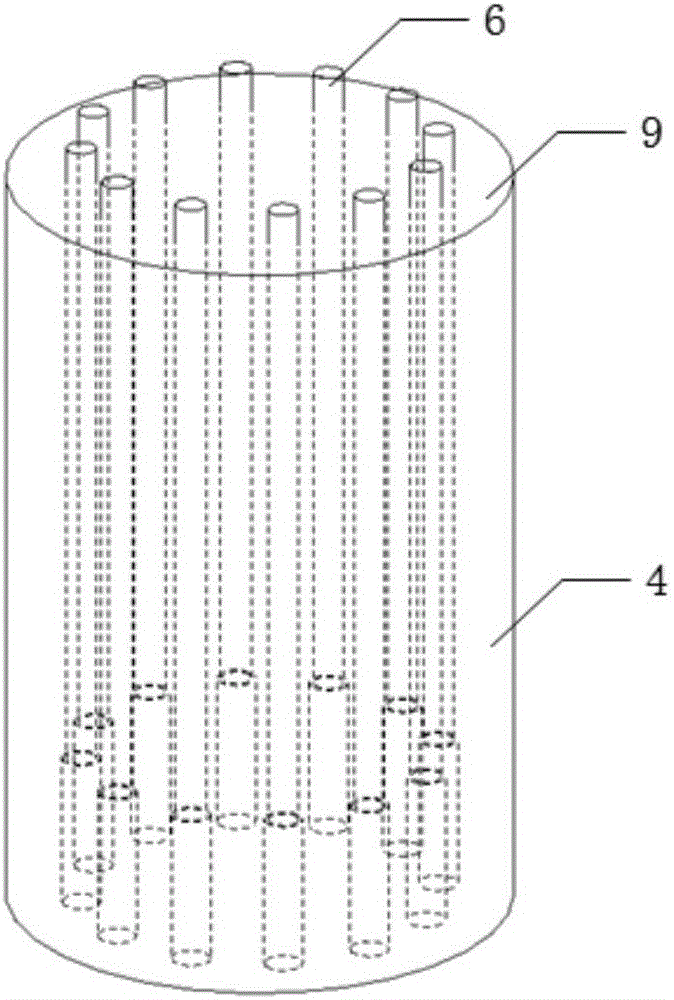

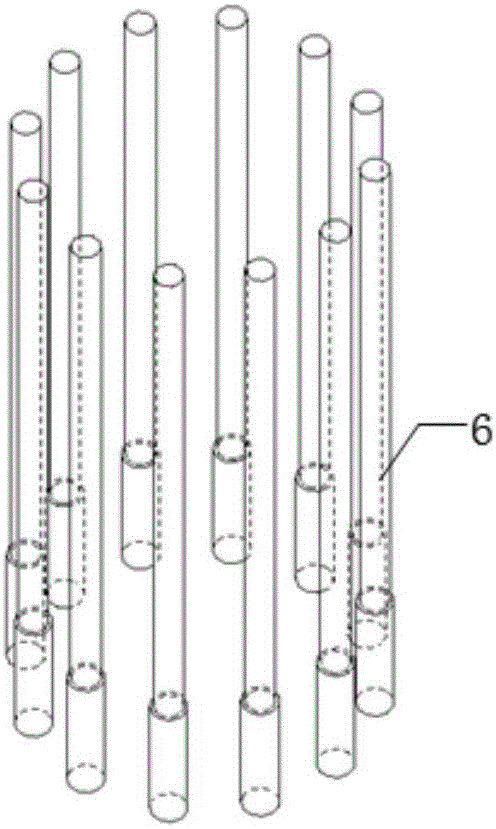

[0029] see figure 1 and 5 , an integrally assembled pier of a bridge: including 2 sets of assembled PHC pipe piles 1, 2 assembled caps 2, 1 assembled tie beam 3, 2 segmental prefabricated pier bodies 4, 1 assembled cover beam 5. Two pier body anchoring end bases 7. Among them, the assembled PHC pipe pile 1 is a pile group architecture, such as figure 2 and 3 shown. A fabricated cap 2 is connected to the top of each fabricated PHC pipe pile 1 . Two fabricated caps 2 are connected by a fabricated tie beam 3 .

[0030] On the top of each fabricated cap 2 there is a pier body anchoring end base 7, such as Figure 4 shown. The segmental prefabricated pier body 4 and the prefabricated cover beam 5 are installed on the top of the base 7 at the anchorage end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com