Dyeing equipment and method allowing dye liquor to flow inwards and outwards at the same time

A technology of dyeing equipment and water flow, which is applied in the field of cheese dyeing, can solve problems such as energy waste, and achieve the effect of reducing pollution discharge, huge economic and social benefits, and uniform combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific drawings and embodiments.

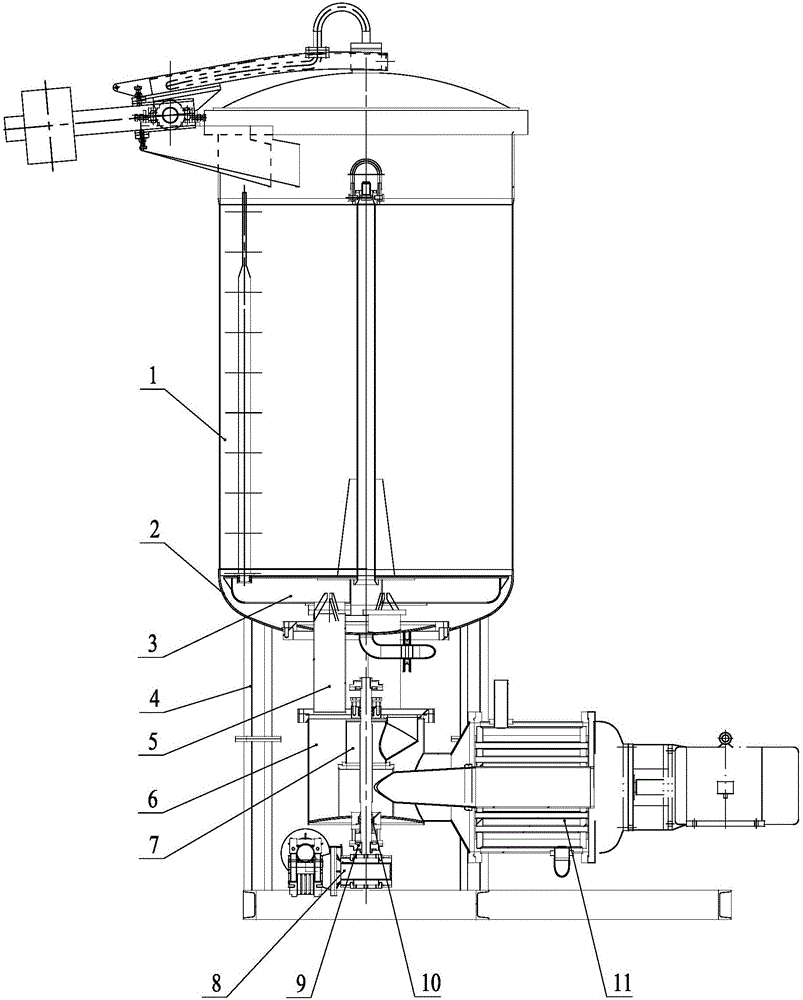

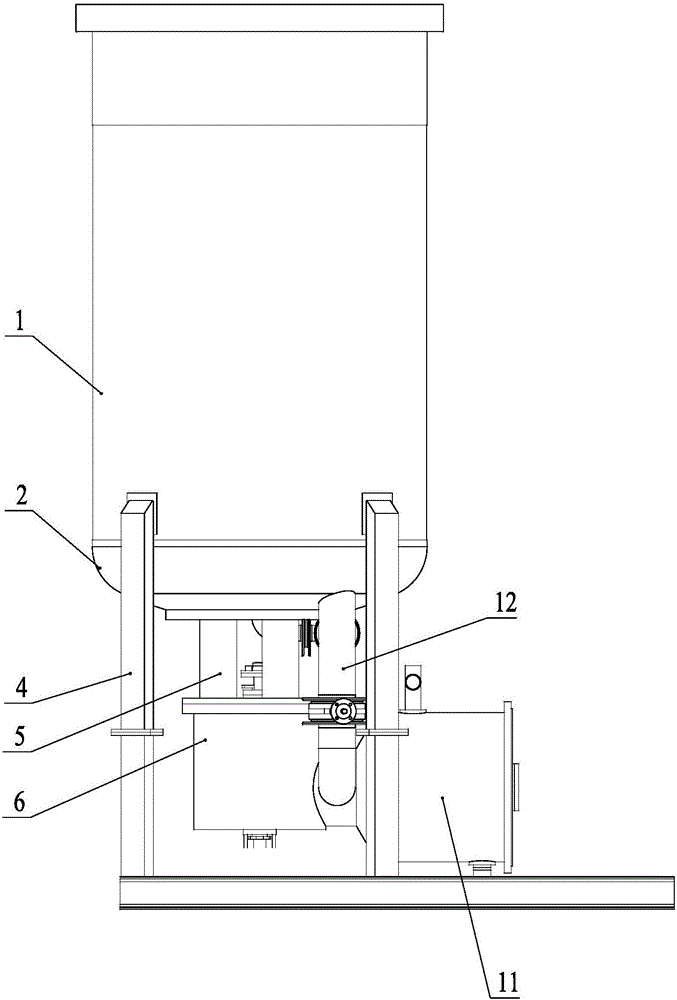

[0033] As shown in the figure: the dyeing equipment in the embodiment is mainly composed of a cylinder body 1, a head 2, a bobbin creel 3, a support frame 4, a shunt pipe 5, a flow regulating pipe 6, a flow regulating shell 7, a reduction motor 8, a support The bearing 9, the sealing ring 10, the water pump 11 and the auxiliary return pipe 12 etc. are composed.

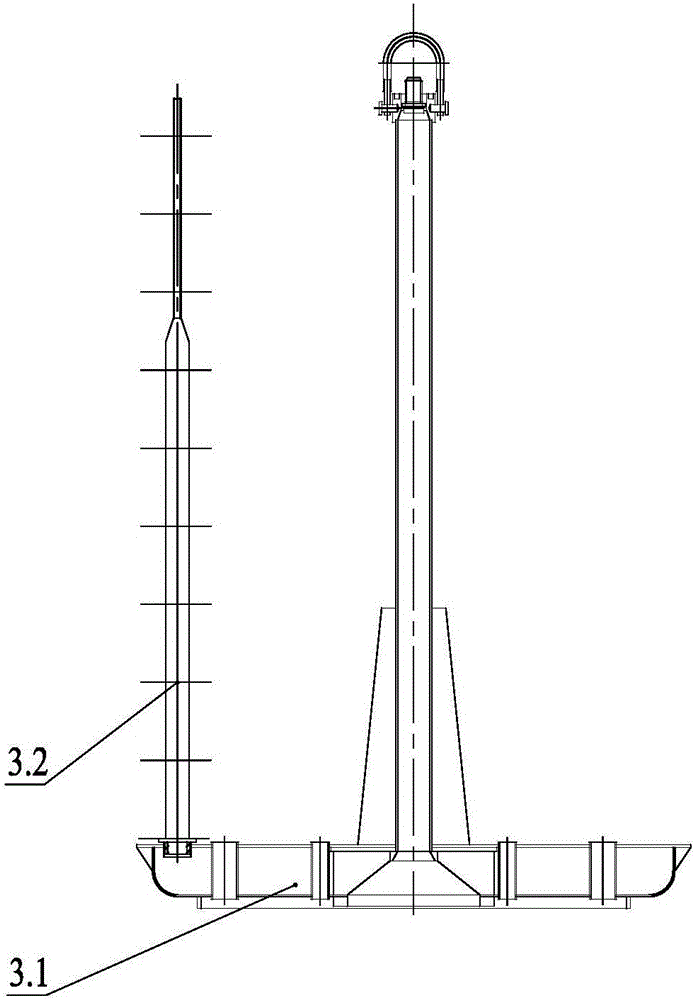

[0034] likefigure 1 , figure 2 As shown, the head 2 is welded to the lower end of the cylinder body 1 to form an airtight container, which is supported and fixed by the support frame 4; the cheese creel 3 is placed inside the cylinder body 1, and the cheese creel 3 includes The disc body 3.1 and the yarn rod 3.2, the disc body 3.1 is hollow inside, and several yarn rods 3.2 are evenly distributed on the disc body 3.1, the yarn rod 3.2 is hollow inside, and the lower end opening of the yarn rod 3.2 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com