A method for preparing nano-ceramic coating interface on the surface of ABS products

A technology of nano-ceramics and products, which is applied in the direction of coating, superimposed layer plating, metal material coating technology, etc., which can solve the problems of sulfuric acid corrosion resistance, high temperature resistance, poor affinity of ceramic coatings, etc., to ensure the combination force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0043] The ABS product of the present invention includes plastic workpieces or products made of various materials such as ABS.

[0044] The method for preparing the nano-ceramic coating interface on the surface of the above-mentioned ABS product may further comprise the steps:

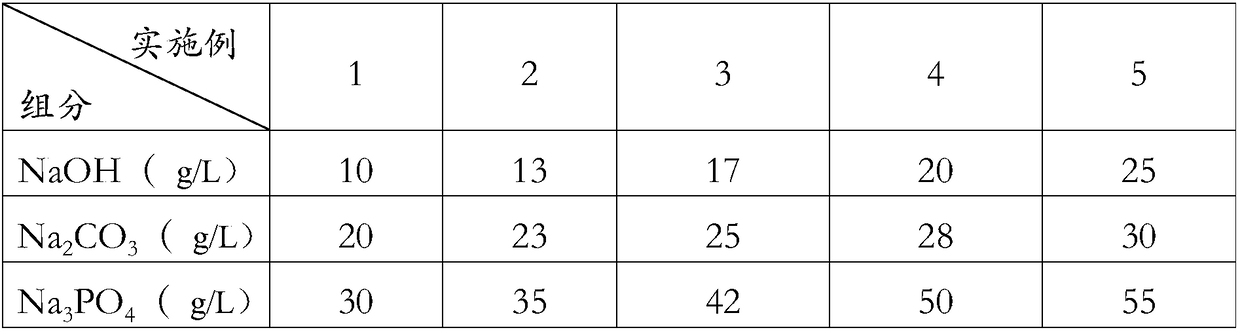

[0045] (1) Surface degreasing: in Na 3 PO 4 、Na 2 CO 3and NaOH mixed solution for cleaning. In this step, the concentration ratio of each component in the mixed solution in different embodiments is shown in Table 1:

[0046] Table I

[0047]

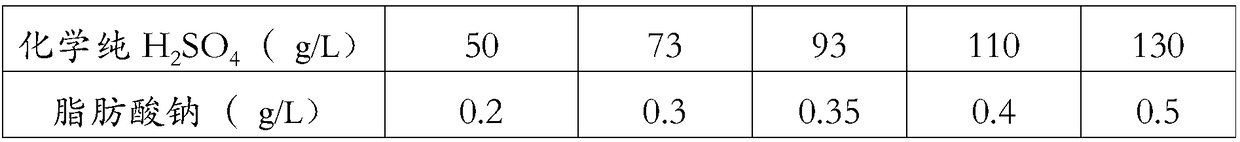

[0048] (2) Surface hydrophilic treatment: in chemically pure H 2 SO 4 , fatty acid sodium mixed solution to fully wet the surface of the product. In this step, chemically pure H 2 SO 4 See Table 2 for the concentration ratio of Sodium Fatty Acid in different embodiments:

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com