A kind of Acetobacter xylinum improved fermentation medium

A fermentation medium, the technology of Acetobacter xylinum, applied in the field of improved fermentation medium of Acetobacter xylinum, can solve the problems of prolonging the fermentation period, reducing the activity of Acetobacter xylinum, etc., so as to increase the final yield, shorten the fermentation period, and improve production efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation of seed liquid among the present invention and parameter monitoring can refer to existing method, and wherein seed liquid can be made through the following steps:

[0017] The strains preserved at 4°C were kept at 30°C for 20 minutes, and a ring of strains was picked up with an inoculation loop and streaked on the solid plate medium, and the plate was cultured in a 30°C incubator for 36 hours. Composition of solid medium (g / 100mL): glucose 2.0, sucrose 1.0, magnesium sulfate 0.04, citric acid 0.11, sodium dihydrogen phosphate 0.25, peptone 1.0, agar 1.8, yeast extract powder 0.1. pH=6.0. Sterilize at 121°C for 30 minutes;

[0018] Pick 2-3 loops of the obtained activated seeds with an inoculation loop, inoculate them into a 500mL Erlenmeyer flask containing 1 / 5 of the seed solution, and then put them in a shaker and shake them back and forth at 120-160rpm for 48h. Seed solution composition (g / 100mL): glucose 2.0, ammonium sulfate 0.6, potassium dihydrog...

Embodiment 1

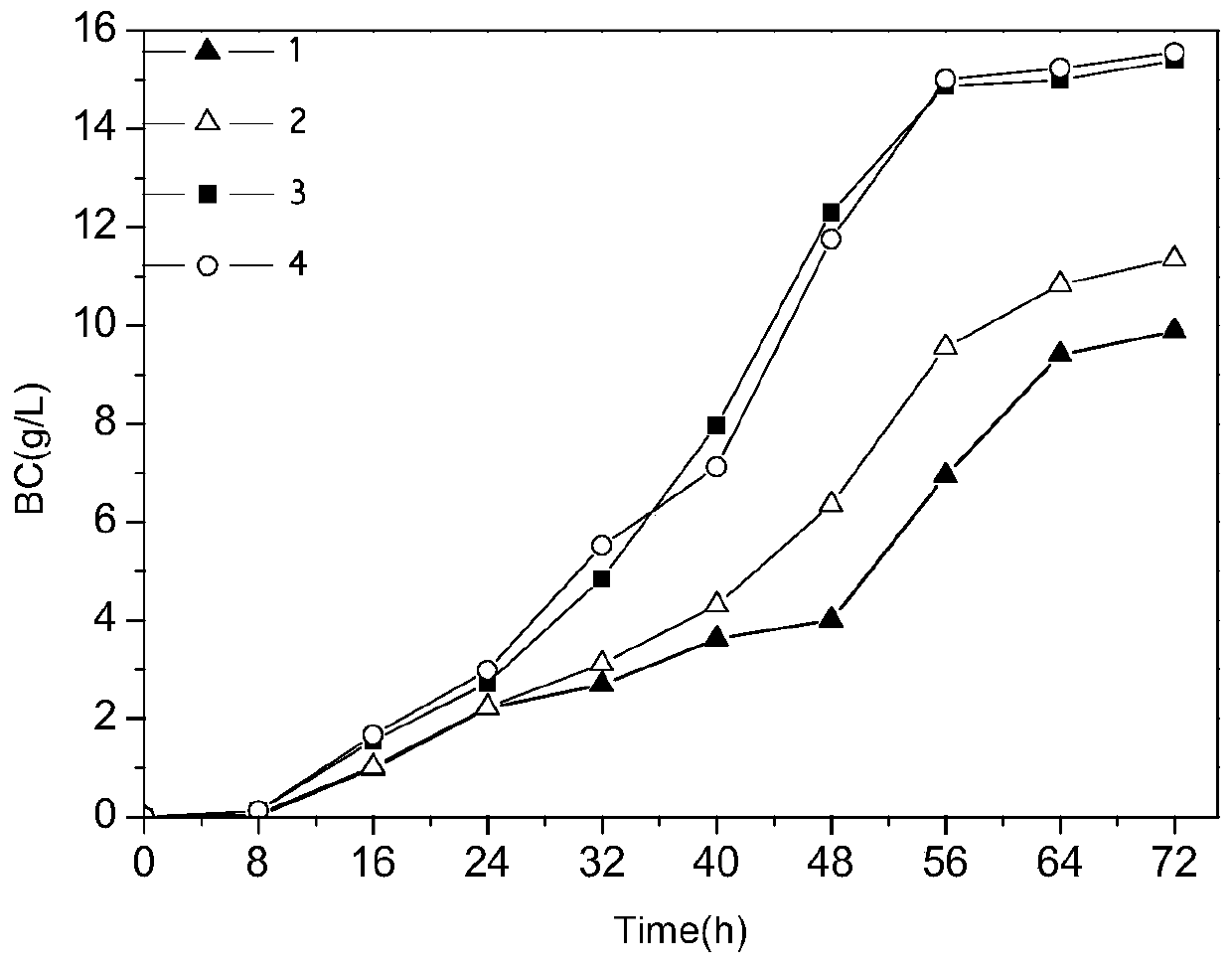

[0023] The seed solution was added to 40 shake flasks, and each shake flask contained 100mL of fermentation broth, and the addition ratio was 5mL of seed solution to 100mL of fermentation broth. Fermentation broth composition (g / 100mL): glucose 2.5, sucrose 3.0, ammonium sulfate 0.12, potassium dihydrogen phosphate 0.6, magnesium sulfate 0.07, calcium lactate 0.03, peptone 1.5, yeast extract powder 1.0, acetic acid 0.3, citric acid 0.08, carboxymethyl Base cellulose sodium 0.04. Mark the shaker flasks into 1-4 groups, 10 in each group, and add gluconic acid / sodium gluconate (1:1): 0g, 2g, 5g, 10g to each group respectively. Sterilize at 121°C for 30 minutes before adding the seed solution.

[0024] The above 40 shake flasks were placed in a shaker at 160-200rpm for dynamic culture. Take out each shake flask in 1~4 groups every 8h, carry out the mensuration of cellulose content according to the method for BC production monitoring in parameter monitoring, the result is as foll...

Embodiment 2

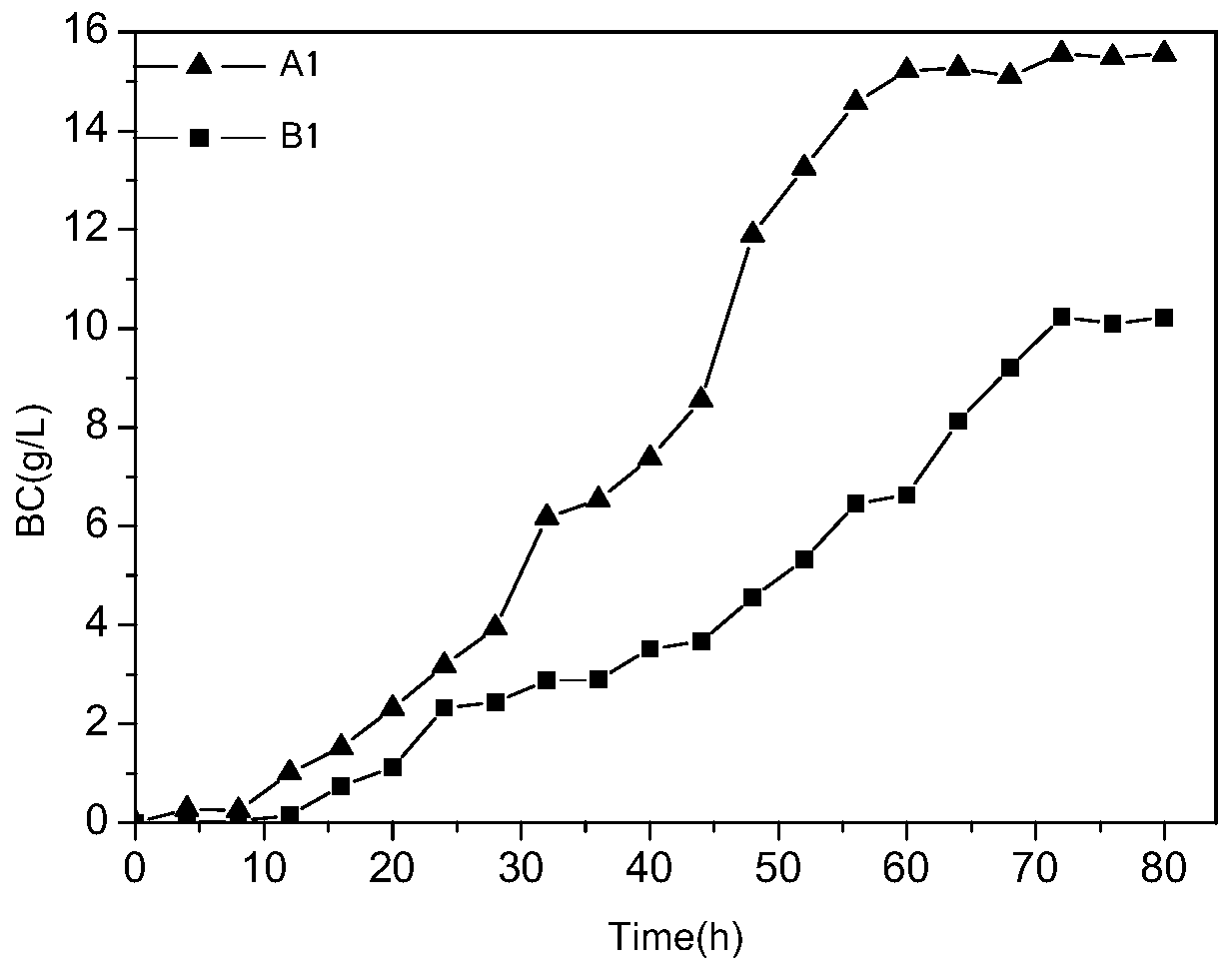

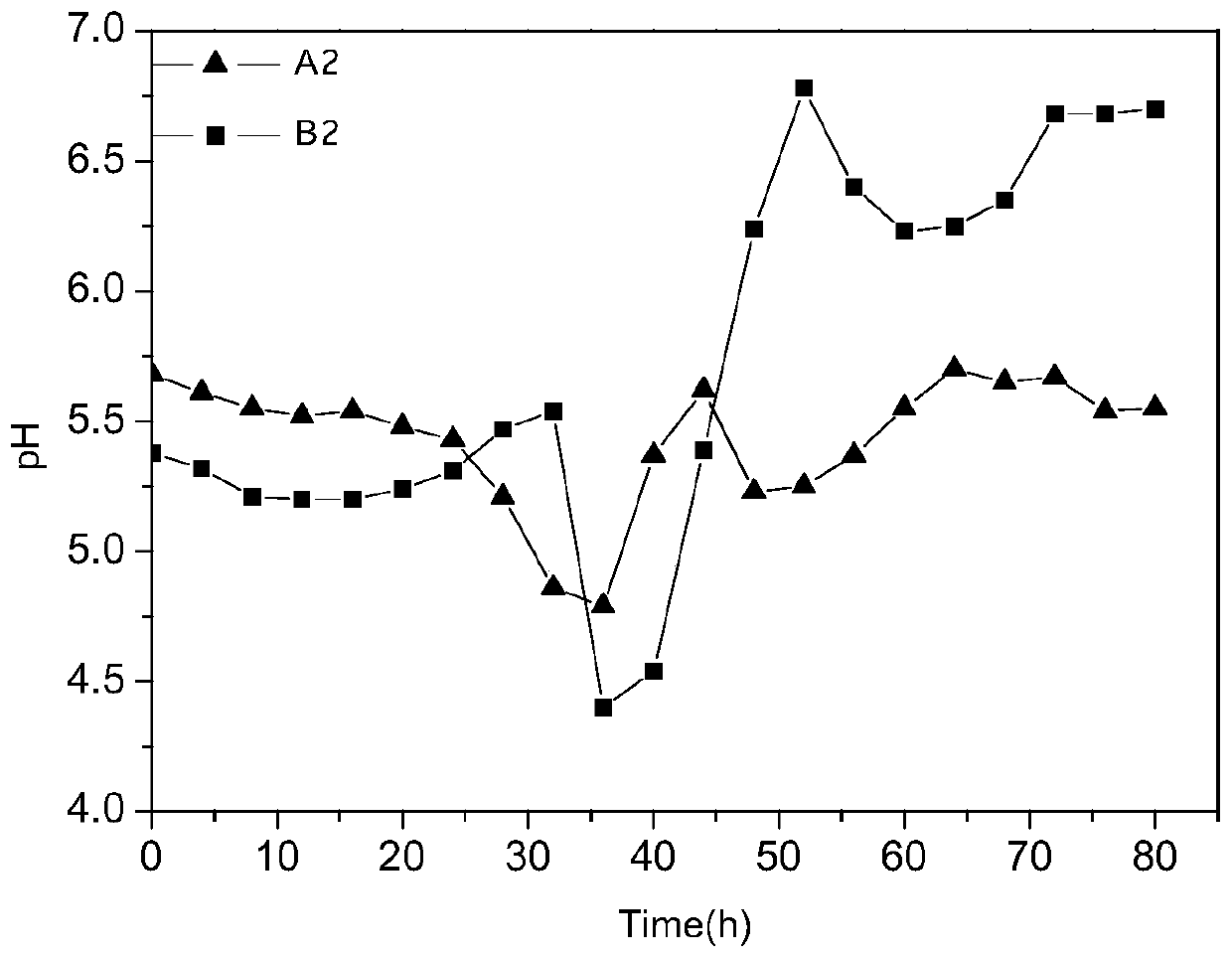

[0027] In order to further obtain the yield change in the fermentation process, the sampling interval can be further shortened to 4h.

[0028] The seed solution was added to 40 fermentation broths containing 100mL, and the addition ratio was 8mL seed solution to 100mL fermentation broth. Fermentation broth composition (g / 100mL): glucose 2.25, sucrose 2.75, ammonium sulfate 0.1, potassium dihydrogen phosphate 0.5, magnesium sulfate 0.07, calcium lactate 0.02, peptone 1.0, yeast extract powder 0.75, acetic acid 0.15, citric acid 0.06, carboxymethyl Base cellulose sodium 0.04. To 20 of these shake flasks, 5 g of gluconic acid / sodium gluconate (1:3) was added to each shake flask, and the bottles containing gluconic acid / sodium gluconate were marked as category A1 and the rest as category B1. Sterilize at 121°C for 30 minutes before adding the seed solution.

[0029] The above 40 shake flasks were placed in a shaker at 160-200rpm for dynamic culture. Every 4h, take out each shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com