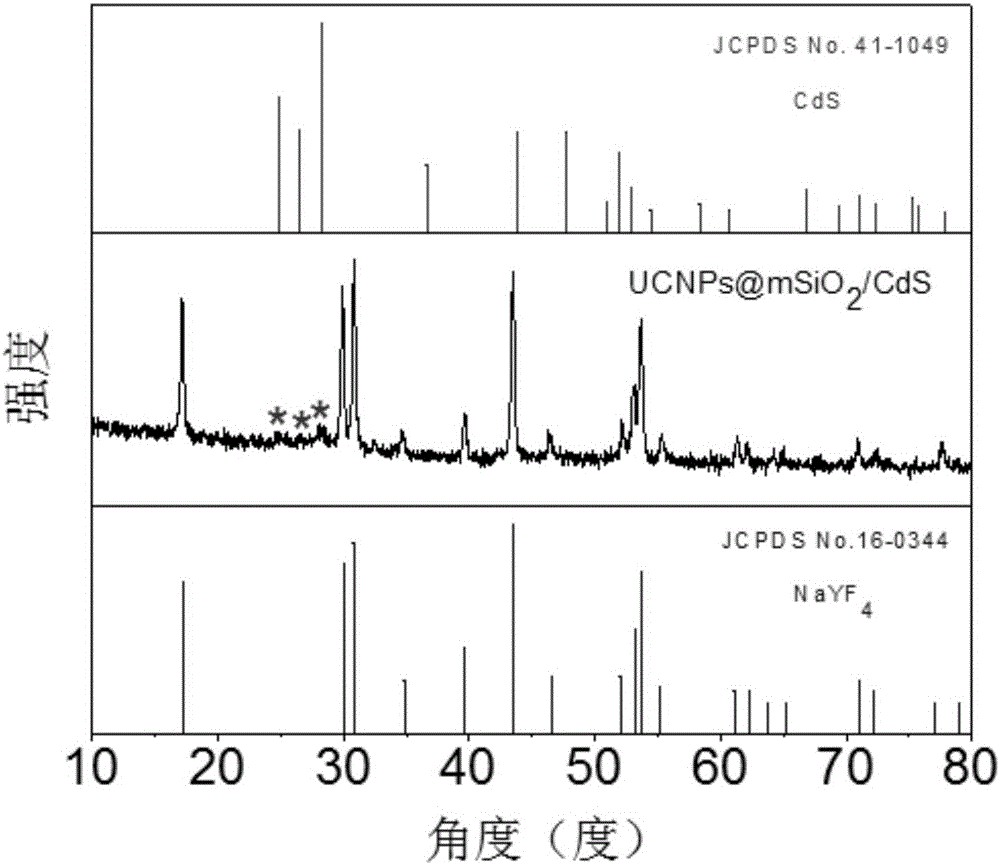

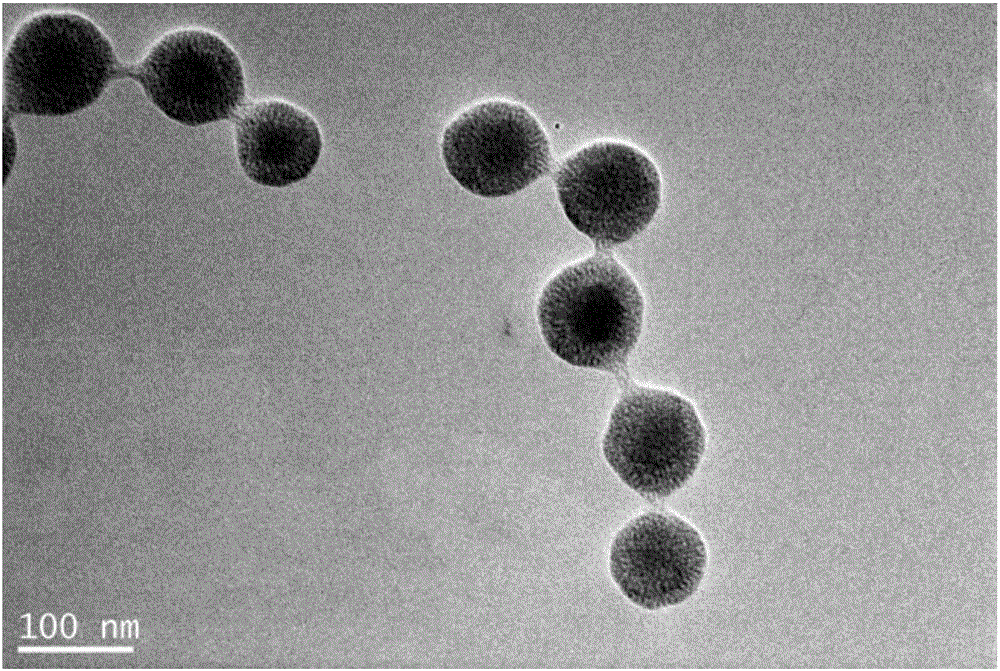

Preparation method of beta-NaYF4:Yb/Tm@Cds core-shell nanostructure

A core-shell and nanoparticle technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of cumbersome preparation methods, harsh conditions, and complex processes, and achieve simple operation, The effect of mild reaction, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment prepares β-NaYF according to the following steps 4 :Yb / Tm@CdS core-shell nanoparticles:

[0026] a. Weigh 0.1357g YCl 3 , 0.0838g YbCl 3 and 0.0014g TmCl 3 Put it into the reactor, add 5mL oleic acid and 15mL octadecene, stir evenly, heat to 150°C and keep it warm at this temperature for 0.5h to obtain a clear clear liquid; cool the clear clear liquid to room temperature, add 4mL solvent dropwise There are 0.3652g NH 4 F and 0.2464g NaOH methanol solution, stirred at room temperature for 0.5h, then heated to 150°C and kept for 0.5h to remove methanol, and finally heated to 240°C under nitrogen protection flow, kept for 2h to obtain NaYF 4 : Yb / Tm nanoparticles.

[0027] b. Weigh 5.0 mg of NaYF prepared above 4 : Put Yb / Tm nanoparticles in a flask, add 2mL cyclohexane for ultrasonic dispersion, then add 20mL water and 0.5mg cetyltrimethylammonium bromide, stir at room temperature for 6h, and centrifuge to obtain water-soluble β-NaYF 4 : Yb / Tm nanop...

Embodiment 2

[0033] This embodiment prepares β-NaYF according to the following steps 4 :Yb / Tm@CdS core-shell nanoparticles:

[0034] a, prepare NaYF by the same method as in Example 1 4 : Yb / Tm nanoparticles.

[0035] b. Weigh 200mg of NaYF prepared above 4 : Yb / Tm nanoparticles in a flask, add 2mL cyclohexane ultrasonic dispersion, then add 20mL water and 50mg cetyltrimethylammonium bromide, stir at room temperature for 24h, centrifuge to get water-soluble β-NaYF 4 : Yb / Tm nanoparticles.

[0036] c. Weigh 90 mg of water-soluble β-NaYF 4 : Yb / Tm nanoparticles and 109mg cetyltrimethylammonium bromide, add 15mL water ultrasonic dispersion, then add 150mg ascorbic acid, 250mg Cd(NO 3 ) 2 and 200mg of hexamethylenetetramine, stirred and dissolved, and reacted at 95°C for 6 hours; naturally cooled to room temperature, and centrifuged to obtain β-NaYF 4 :Yb / Tm@CdO core-shell nanoparticles.

[0037] d. The resulting β-NaYF 4 : Yb / Tm@CdO nanoparticles were placed in a tube furnace, and H ...

Embodiment 3

[0040] This embodiment prepares β-NaYF according to the following steps 4 :Yb / Tm@CdS core-shell nanoparticles:

[0041] a, prepare NaYF by the same method as in Example 1 4 : Yb / Tm nanoparticles.

[0042] b. Weigh 100mg of NaYF prepared above 4 : Yb / Tm nanoparticles in a flask, add 2mL cyclohexane ultrasonic dispersion, then add 20mL water and 10mg cetyltrimethylammonium bromide, stir at room temperature for 15h, centrifuge to get water-soluble β-NaYF 4 : Yb / Tm nanoparticles.

[0043] c. Weigh 26 mg of water-soluble β-NaYF 4 : Yb / Tm nanoparticles and 30mg cetyltrimethylammonium bromide, add 15mL water ultrasonic dispersion, then add 27mg ascorbic acid, 30mg Cd(CH 3 COO) 2 and 5.0mg of hexamethylenetetramine, stirred and dissolved, reacted at 85°C for 10 hours; naturally cooled to room temperature, centrifuged and dried to obtain β-NaYF 4 :Yb / Tm@CdO core-shell nanoparticles.

[0044] d. The resulting β-NaYF 4 : Yb / Tm@CdO nanoparticles were placed in a tube furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com