Metal section bar protection film and production method thereof

A metal profile and protective film technology, applied in the direction of adhesive type, pressure-sensitive film/sheet, film/sheet-shaped adhesive, etc., can solve problems such as insufficient cohesion, high curing temperature, mixed damage, etc., to achieve The effects of high cohesive strength, good uniformity of film formation on the rubber surface, good laminating performance and peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The metal profile protective film of the present embodiment, its raw material component consumption is as follows:

[0051] Component A 40kg

[0052] Component B 10kg

[0053] Initiator 0.1kg

[0054] Cross-linking agent 0.6kg.

[0055] The initiator uses ammonium persulfate, and the crosslinking agent uses SC-100.

[0056] Wherein, component A and component B are each prepared by the composition of following consumption,

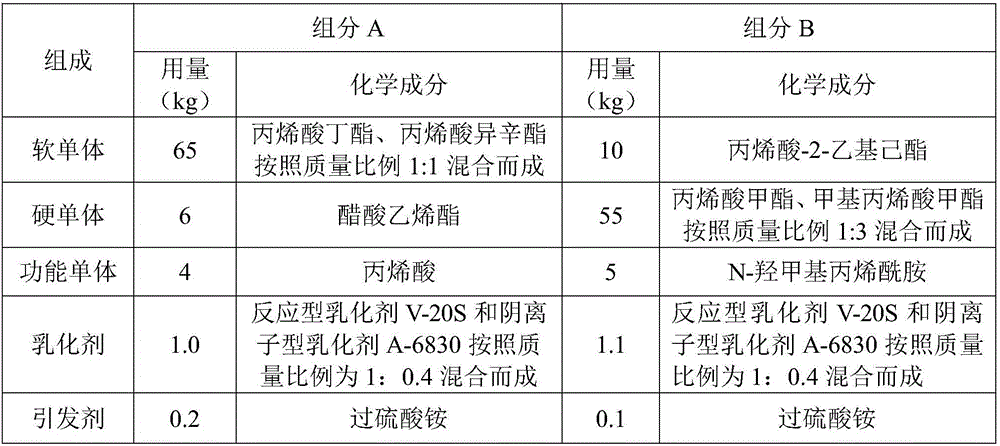

[0057]

[0058] The preparation process is as follows:

[0059] S1, Synthesis of Component A.

[0060] First, add the emulsifier into an emulsification bottle filled with deionized water, stir, and dissolve evenly, then slowly add and mix the soft monomer, hard monomer and functional monomer A, and continue stirring for 30 minutes to obtain a stable pre-emulsion;

[0061] Then, 10% by volume of the pre-emulsion and NaHCO 3 Add the solution into a four-neck flask, stir and heat up to 80°C, condense, add 10% by volume of the initiator, react ...

Embodiment 2

[0071] The metal profile protective film of the present embodiment, its raw material component consumption is as follows:

[0072] Component A 70kg

[0073] Component B 30kg

[0074] Initiator 0.2kg

[0075] Cross-linking agent 1.0kg.

[0076] The initiator uses potassium persulfate, and the crosslinking agent uses GA-240.

[0077] Wherein, component A and component B each have the composition preparation of following consumption,

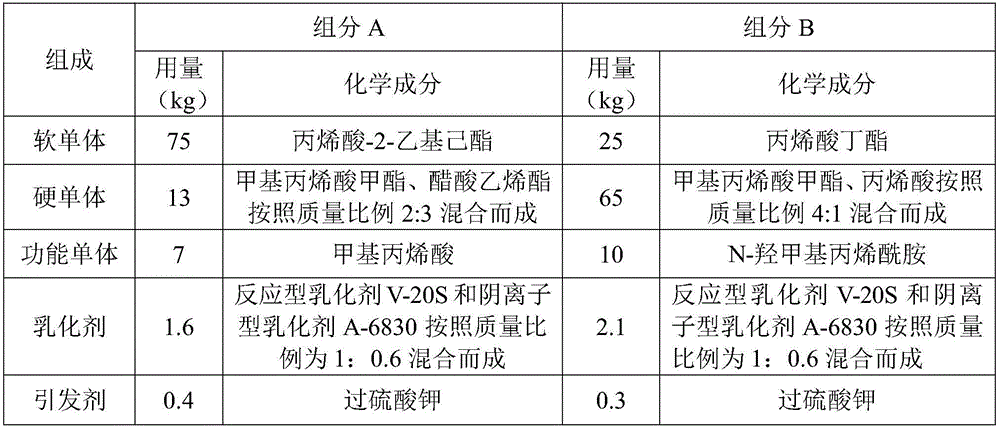

[0078]

[0079] The preparation process is as follows:

[0080] S1, Synthesis of Component A.

[0081] First, add the emulsifier into an emulsification bottle filled with deionized water, stir, and dissolve evenly, then slowly add and mix the soft monomer, hard monomer and functional monomer A, and continue stirring for 30 minutes to obtain a stable pre-emulsion;

[0082] Then, 10% by volume of the pre-emulsion and NaHCO 3 Add the solution into a four-neck flask, stir and heat up to 80°C, condense, add 10% by volume of the initiator, reac...

Embodiment 3

[0092] The metal profile protective film of the present embodiment, its raw material component consumption is as follows:

[0093] Component A 90kg

[0094] Component B 40kg

[0095] Initiator 0.4kg

[0096] Cross-linking agent 1.4kg.

[0097] The initiator uses ammonium persulfate, and the crosslinking agent uses SC-100.

[0098] Wherein, component A and component B each have the composition preparation of following consumption,

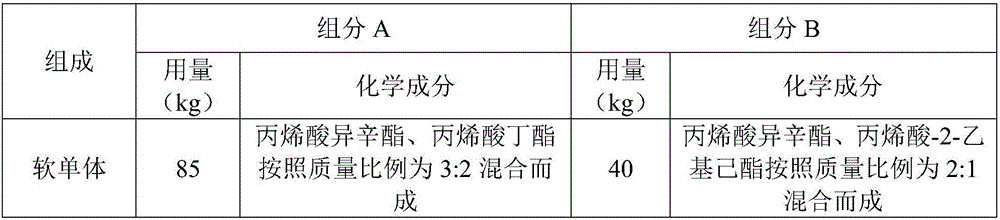

[0099]

[0100]

[0101] The preparation process is as follows:

[0102] S1, Synthesis of Component A.

[0103] First, add the emulsifier into an emulsification bottle filled with deionized water, stir, and dissolve evenly, then slowly add and mix the soft monomer, hard monomer and functional monomer A, and continue stirring for 30 minutes to obtain a stable pre-emulsion;

[0104] Then, 10% by volume of the pre-emulsion and NaHCO 3 Add the solution into a four-neck flask, stir and heat up to 80°C, condense, add 10% by volume of the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com