Method for purifying electron-grade hydrogen chloride

A purification method and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, chemical instruments and methods, etc., can solve the problems of high cost and large energy consumption, and achieve the effect of improving adsorption capacity and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of aluminum hydrogen resin adsorbent:

[0024] Add 100Kg D201 strong basic macroporous anion exchange resin in the 3000L reactor, the factory form is OH type, add 1500Kg deionized water, 10Kg sodium aluminum hydride NaALH 4 , then add 1Kg of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, soak at 20°C for 72 hours, filter, and then dry until the water content is less than 5ppm to obtain an aluminum hydrogen resin adsorbent;

[0025] (2) Dehydration:

[0026] The raw chemical grade hydrogen chloride is passed into the drying tower equipped with X-type molecular sieve desiccant for deep dehydration, and the water content after dehydration is 0.7ppm.

[0027] (3) refined

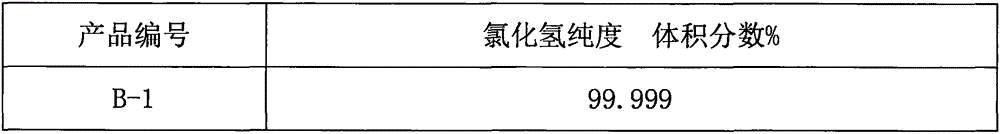

[0028] The dehydrated hydrogen chloride enters a 1000L adsorption tower equipped with 500L aluminum hydrogen resin adsorbent at a temperature of 40°C and a flow rate of 3BV / h to obtain electronic grade hydrogen chloride products. Product number B-1.

Embodiment 2

[0030] (1) Preparation of aluminum hydrogen resin adsorbent:

[0031] Add 100Kg D201 strong basic macroporous anion exchange resin into the 3000L reactor, the factory form is OH type, add 1000Kg deionized water, 5Kg sodium aluminum hydride NaALH 4 , then add 0.5Kg of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, soak at 10°C for 48h, filter, and then dry until the water content is less than 5ppm to obtain aluminum hydrogen resin adsorbent;

[0032] (2) Dehydration:

[0033] The raw chemical grade hydrogen chloride is passed into the drying tower equipped with X-type molecular sieve desiccant for deep dehydration, and the water content after dehydration is 0.8ppm.

[0034] (3) refined

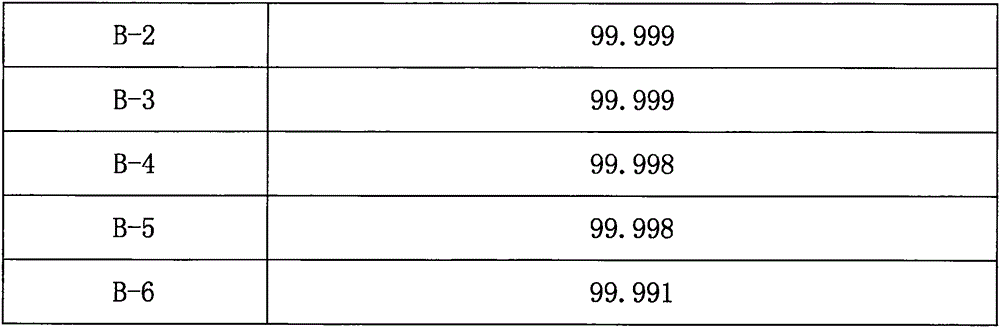

[0035] The dehydrated hydrogen chloride enters a 500L adsorption tower equipped with 200L aluminum hydrogen resin adsorbent at a temperature of 20°C and a flow rate of 1BV / h to obtain electronic grade hydrogen chloride product, product number B-2.

Embodiment 3

[0037] (1) Preparation of aluminum hydrogen resin adsorbent:

[0038] Add 100Kg D201 strong basic macroporous anion exchange resin into the 5000L reactor, the factory form is OH type, add 2000Kg deionized water, 15Kg sodium aluminum hydride NaALH 4 , then add 2Kg of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, soak at 30°C for 240h, filter, and then dry until the water content is less than 5ppm to obtain an aluminum hydrogen resin adsorbent;

[0039] (2) Dehydration:

[0040] The raw chemical grade hydrogen chloride is passed into the drying tower equipped with X-type molecular sieve desiccant for deep dehydration, and the water content after dehydration is 0.5ppm.

[0041] (3) refined

[0042] The dehydrated hydrogen chloride enters a 1000L adsorption tower equipped with 500L aluminum hydrogen resin adsorbent at a temperature of 60°C and a flow rate of 5BV / h to obtain electronic grade hydrogen chloride product, product number B-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com