A kind of high silicon steel laser welding method

A technology of laser welding and high-silicon steel, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems such as the decrease of the mechanical properties of the weld seam and the inability to meet the requirements of tension rolling of silicon steel strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

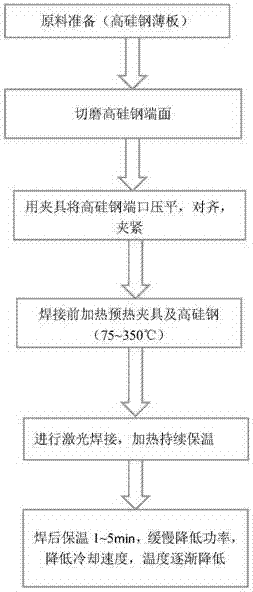

Method used

Image

Examples

Embodiment 1

[0032] Laser welding, using WLS series fiber laser, butt welding of silicon steel and silicon steel, the silicon content of silicon steel is 3.5%, warm rolled plate with a thickness of 0.28mm, pickling, cutting and grinding, clamp flattening, alignment, preheating, double-sided welding, The laser power is 140W and 170W respectively, the defocus is 30mm, the welding speed is 1.0m / min, the airflow is 15L / min, and the preheating temperature is 75°C.

[0033] Double-sided welding, no cracks in the weld, fewer defects on both sides of the weld, no weld leakage, uniform weld, and only a small amount of stress deformation in the middle part, avoiding the occurrence of weld leakage.

Embodiment 2

[0035] Laser welding, using WLS series fiber laser, butt welding of silicon steel and silicon steel, the silicon content of silicon steel is 6.5%, warm rolled plate with a thickness of 0.48mm, pickling, cutting and grinding, clamp flattening, alignment, preheating, double-sided welding, The laser power is 200W, 230W, the defocus is 30mm, the welding speed is 1.2m / min, the airflow is 15L / min, and the preheating temperature is 130℃.

[0036] Double-sided welding, no cracks in the weld seam, fewer defects on both sides of the weld seam, no weld leakage, more uniform weld seam, less weld deformation, beautiful weld seam, and avoid weld leakage.

Embodiment 3

[0038] Laser welding, using WLS series fiber laser, butt welding of silicon steel and silicon steel, the silicon content of silicon steel is 7%, hot-rolled plate with a thickness of 2mm, pickling, cutting, clamping, alignment, preheating, double-sided welding, The laser power is 730W and 890W respectively, the defocus is 30mm, the welding speed is 1.5m / min, the airflow is 20L / min, and the preheating temperature is 350℃.

[0039] Double-sided welding, no cracks in the weld, fewer defects on both sides of the weld, no weld leakage, uniform weld, small weld deformation, and beautiful weld.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com