Freeze drying preparing method for dispersion strengthening tungsten powder

A technology of dispersion strengthening and tungsten powder, which is applied in the field of materials, can solve the problems of long cycle time, poor economy and high energy consumption of dispersed tungsten powder, and achieve the effect of convenient tungsten powder preparation, wide applicability and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

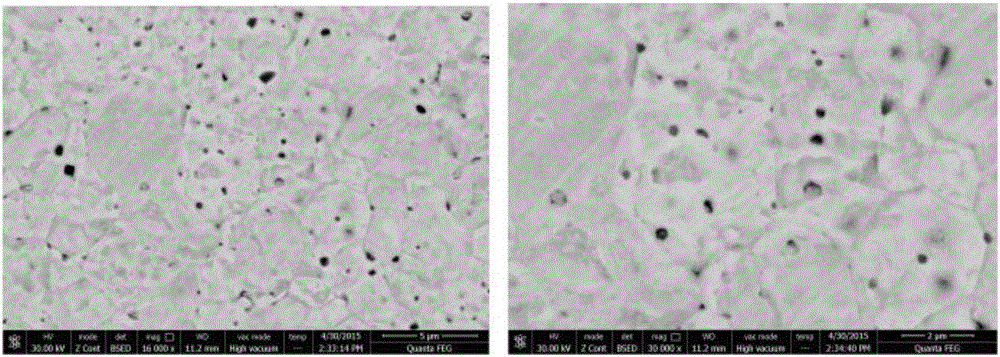

[0033] Such as Figure 1-Figure 6 As shown, the present invention provides a freeze-drying preparation method of dispersion-strengthened tungsten powder. The preparation method utilizes polyvinylpyrrolidone as a joint dispersant, methacrylic acid as a nucleating agent, and liquid nitrogen as a refrigerant. Through vacuum drying technology and The staged calcination reduction process freezes, dries, and calcines the solution dispersed with nano-ceramic particles, rare earth nitrates or a combination of the two into dispersion-strengthened tungsten powder;

[0034] Described preparation method comprises:

[0035] S1: preparing a precursor solution; the S1 specifically includes:

[0036] S11: using ammonium metatungstate as a tungsten source, and using deionized water to prepare a solution, the mass ratio of tungsten in the ammonium metatungstate to deionized water is 1:5-1:10;

[0037] S12: Add PVP and MA respectively to the solution in S11, and stir to dissolve them evenly; ...

Embodiment 1

[0047] 1. Preparation of precursors doped with ceramic nanoparticles:

[0048]1) Ammonium metatungstate is used as the tungsten source, and deionized water is used to prepare a solution. The mass ratio of tungsten (converted from ammonium metatungstate) to deionized water is 1:5-1:10. Add 0.1%-3% PVP and MA in deionized water quality, stir to make them dissolve evenly.

[0049] 2) Add nano-ceramic powder (such as titanium carbide) that needs to be dispersed into the solution according to the designed mass percentage (0.1% to 2%), and fully stir evenly. Disperse in ultrasonic for 1h.

[0050] 2. Precursor freezing and drying:

[0051] The dispersed solution is sprayed into a container containing liquid nitrogen with a special nozzle. Due to the huge supercooling degree of liquid nitrogen, the sprayed solution is quickly frozen into small droplets and sinks into the container. These frozen The small droplets exist in the form of spheres, which are collected and placed in a va...

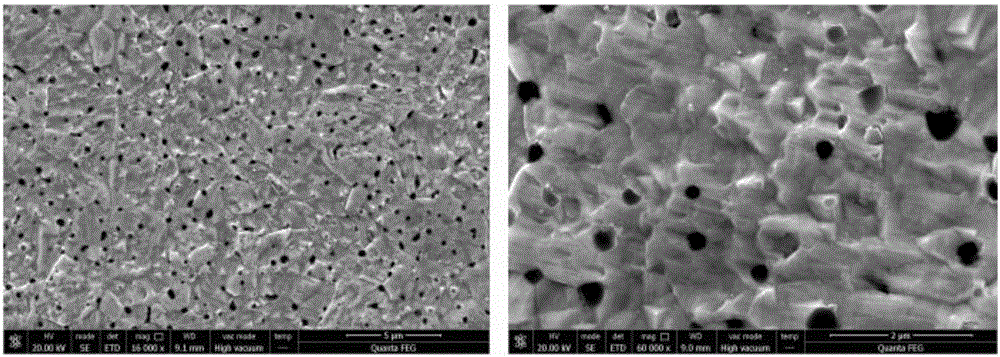

Embodiment 2

[0056] 1. Preparation of precursors for doping rare earth oxides:

[0057] 1) Ammonium metatungstate is used as the tungsten source, and deionized water is used to prepare a solution. The mass ratio of tungsten (converted from ammonium metatungstate) to deionized water is 1:5-1:10. Add PVP and MA with 0.1%-3% deionized water quality respectively into the solution, and stir to make them dissolve evenly.

[0058] 2) The required rare earth nitrate is added into the solution according to the designed mass percentage (0.1% to 2%), and fully stirred evenly.

[0059] 2. Precursor freezing and drying:

[0060] The dispersed solution is sprayed into a container containing liquid nitrogen with a special nozzle. Due to the huge supercooling degree of liquid nitrogen, the sprayed solution is quickly frozen into small droplets and sinks into the container. These frozen The small droplets exist in the form of spheres, which are collected and placed in a vacuum dryer for sublimation of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com