A copper-iron powder metallurgy tube and its application

A technology of powder metallurgy and copper-iron, which is applied in the field of copper-iron powder metallurgy pipes and their preparation, can solve the problems of low flame brazing welding efficiency, high cost of pure copper pipes, and harsh working environment, so as to reduce welding cost and difficulty, The effect of convenient processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

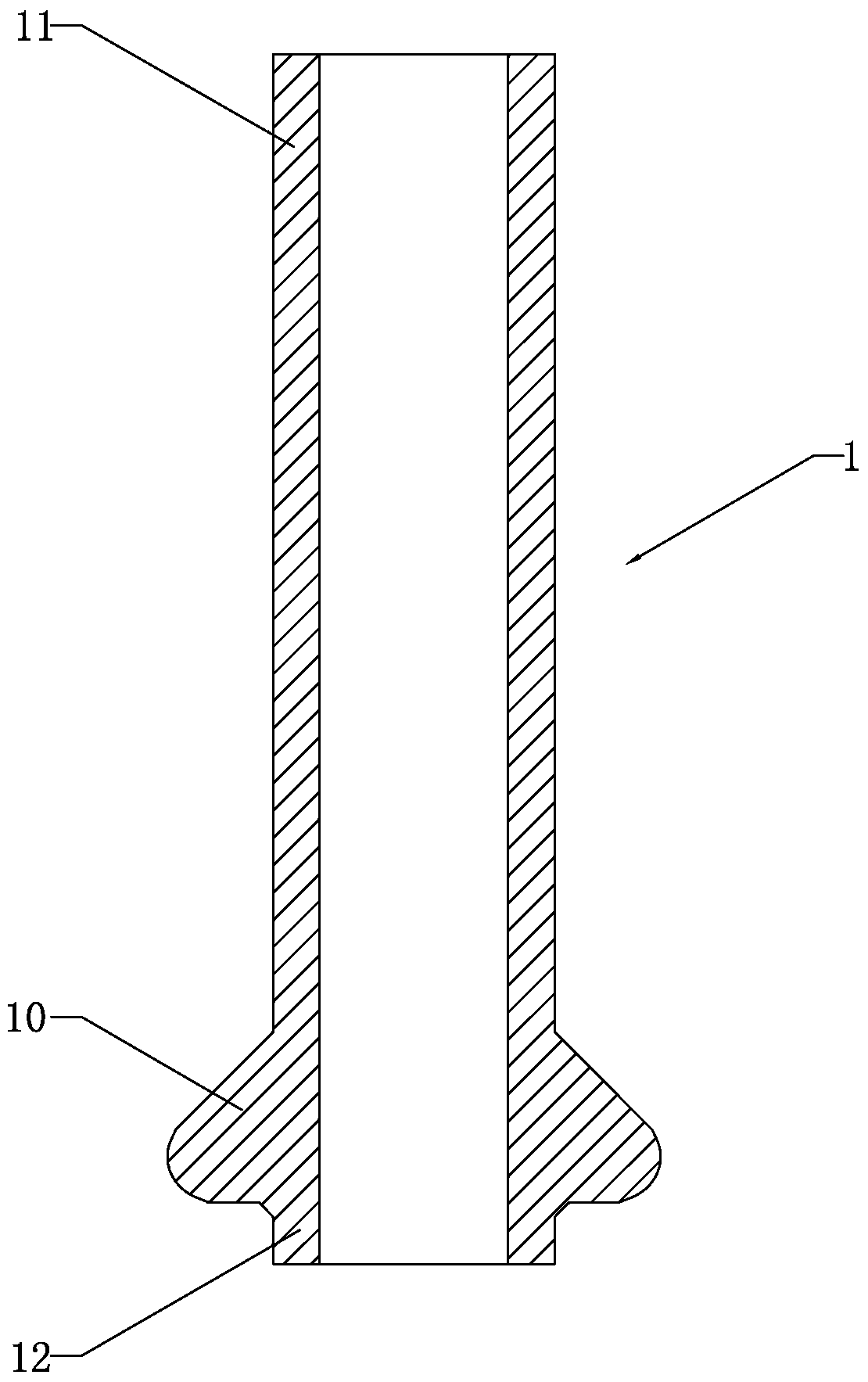

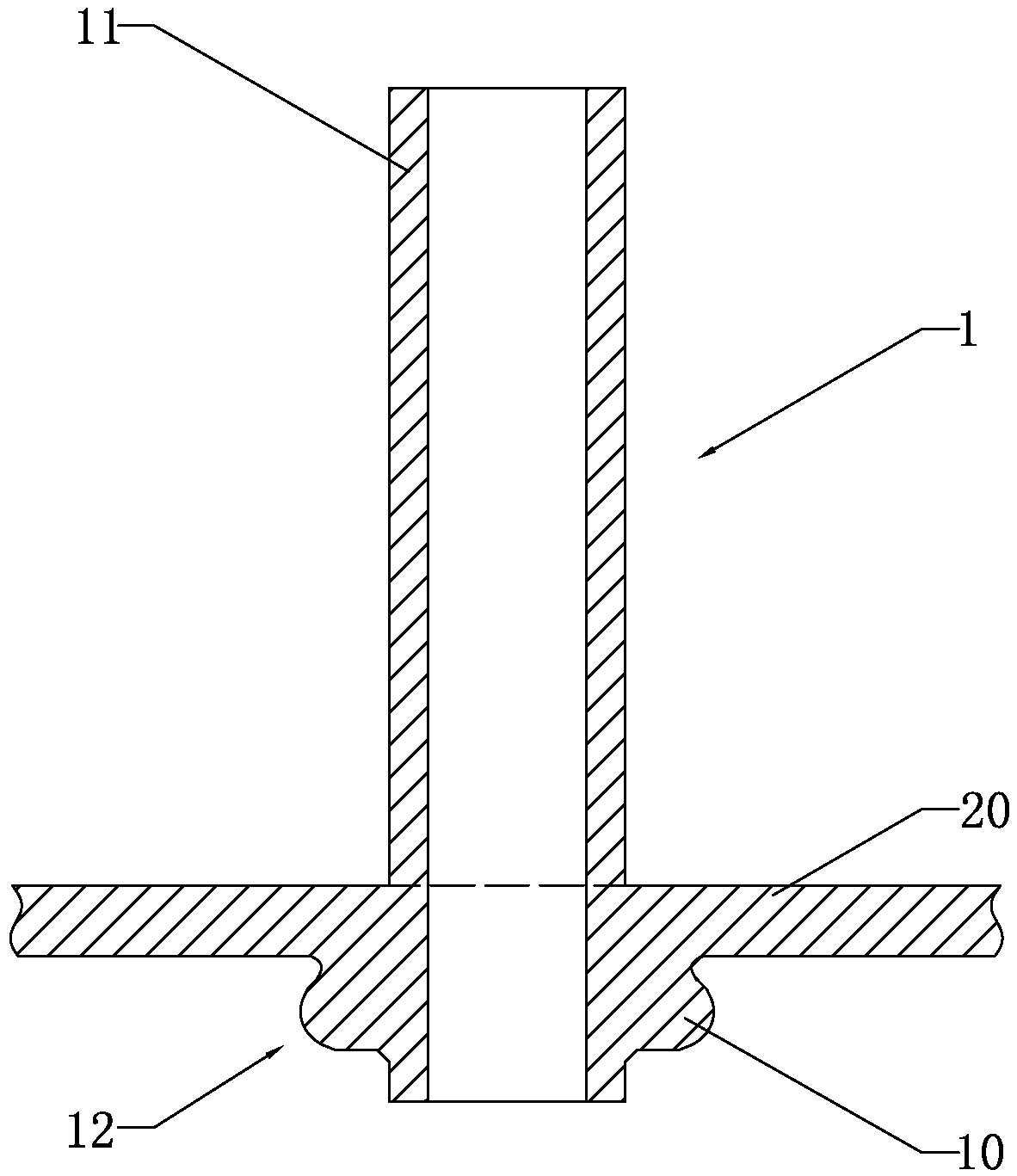

[0035] See Figure 1-2 , a copper-iron powder metallurgy tube, comprising a metallurgical tube body 1, the metallurgical tube body 1 is made of copper powder and iron powder or copper powder and stainless steel powder, the metallurgical tube body 1 includes a copper welding end 11 and an iron welding end 12 , The iron welding end 12 is fixed with the boss 10 .

[0036] The metallurgical pipe body 1 is formed by mixing and pressing copper powder and iron powder. The iron powder weight content of the brazed end 11 of the metallurgical pipe body 1 is less than 50%. Specifically, the iron powder weight content of the brazed end 11 can be 45%. %, 40%, 35%, 30%, 25%, 20%, 15%, 10% or 5%; the copper powder weight content of the iron welding end 12 is less than 30%, specifically, the copper powder weight of the iron welding end 12 The content can be 25%, 20%, 15%, 10% or 5%.

[0037] Another preferred embodiment of the present invention is: the above-mentioned iron powder is replace...

Embodiment 2

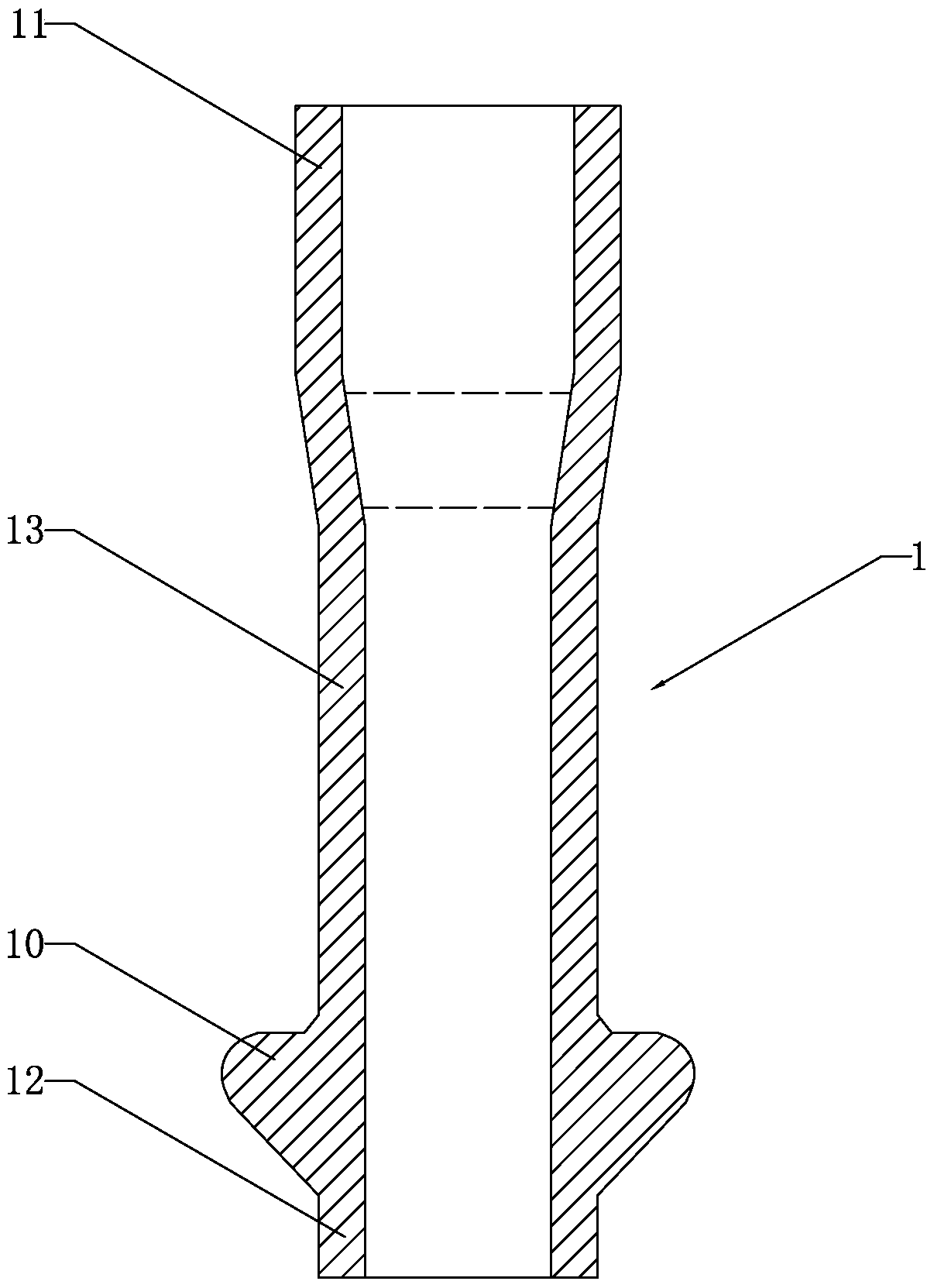

[0042] See Figure 3-4 The difference between this embodiment and the above-mentioned embodiment 1 is that: the metallurgical pipe body 1 also includes an intermediate transition section 13 arranged between the brazing end 11 and the iron welding end 12, and the metallurgical pipe body 1 The brazing end 11 is formed by pressing copper powder, the iron welding end 12 is formed by pressing iron powder, and the intermediate transition section 13 is formed by mixing and pressing copper powder and iron powder.

[0043] Another preferred embodiment of the present invention is: the above-mentioned iron powder is replaced by stainless steel powder. That is, the brazing end 11 of the metallurgical pipe body 1 is formed by pressing copper powder, the iron welding end 12 is formed by pressing stainless steel powder, and the intermediate transition section 13 is formed by mixing and pressing copper powder and stainless steel powder.

Embodiment 3

[0045]A method for preparing a copper-iron powder metallurgy pipe, comprising the steps of:

[0046] (1) Raw material preparation: Weigh copper powder and iron powder as raw materials according to needs, and set aside;

[0047] (2) Mold preparation: Prepare and install the molds required for copper-iron powder metallurgy tube pressing;

[0048] (3) Extrusion molding: heat and pressurize copper powder and iron powder to form a semi-finished product;

[0049] (4) Sealing treatment: the semi-finished product is oxidized and sealed to obtain a copper-iron powder metallurgy tube;

[0050] (5) Cutting process: cutting the iron welding end 12 of the copper-iron powder metallurgy tube to remove the sealing oxide layer on the surface of the iron welding end 12 .

[0051] In the step (1), the copper powder is water-atomized copper powder, the iron powder is water-atomized iron powder, and the particle diameters of the copper powder and the iron powder are both 500 μm.

[0052] In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com