Method for preparing ethylene through ethanol dehydration

A technology of ethanol and ethanol steam, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of high COD value of wastewater, large loss of ethanol, etc., achieve good economic results, reduce energy, increase speed and balance conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

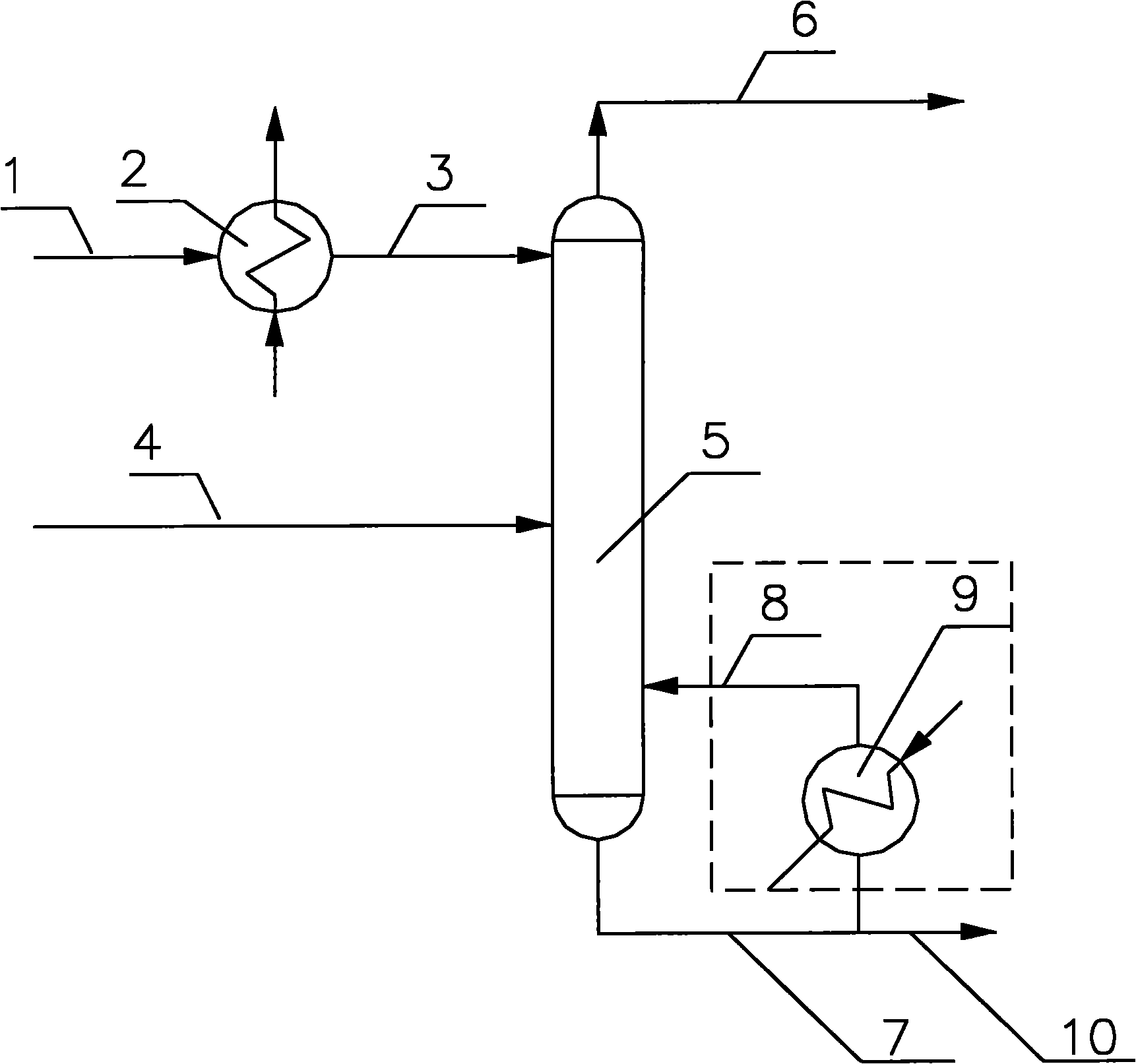

[0017] use figure 1 In the process flow shown, the stripping column is a plate column with a theoretical plate number of 50 and an operating pressure of 0.6MPa(G). Raw material ethanol 2350kg / h, wherein ethanol 1997.5kg / h, water 352.5kg / h, ethanol content 85% (wt%). Raw ethanol is fed from the top of the stripping tower. Ethanol 66.08kg / h, water 1932kg / h in the recovered mixed solution, the feeding position is at the 8th theoretical plate from the top of the stripping tower. The steam discharged from the top of the stripping tower is sent to the dehydration reaction system, wherein the ethanol content is 93.8% (wt%). The ethanol in the water discharged from the bottom of the stripping tower contains 0.05% (wt%), and the COD value in the waste water can be less than 300ppm.

Embodiment 2

[0019] use figure 1 In the process flow shown, the stripping tower is a plate tower with a theoretical plate number of 30 and an operating gauge pressure of 0.9 MPaG. Raw material ethanol 2350kg / h, wherein ethanol 2210kg / h, water 140kg / h, ethanol content 94% (wt%). Raw ethanol is fed from the top of the stripping tower. In the recovered mixed solution, ethanol is 76.25kg / h, water is 1725kg / h, and the feeding position is at the 21st theoretical plate from the top of the stripping tower. The ethanol vapor discharged from the top of the stripping tower is sent to the dehydration reaction system, wherein the ethanol content is 98% (wt%). The ethanol content in the water discharged from the bottom of the stripping tower is 0.1% (wt%), and the COD value in the waste water is less than 500ppm.

Embodiment 3

[0021] use figure 1 In the process flow shown, the stripping tower is a plate tower with a theoretical plate number of 10 and an operating gauge pressure of 4MPaG. Raw material ethanol 2350kg / h, wherein ethanol 1739kg / h, water 611kg / h, ethanol content 74% (wt%). Raw ethanol is fed from the top of the stripping tower. In the recovered mixed solution, ethanol is 46.25kg / h, water is 1725kg / h, and the feeding position is at the 21st theoretical plate from the top of the stripping tower. The ethanol vapor discharged from the top of the stripping tower is sent to the dehydration reaction system, wherein the ethanol content is 90% (wt%). The ethanol content in the water discharged from the bottom of the stripping tower is 0.08% (wt%), and the COD value in the waste water is less than 400ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com