Method for preparing cocoa butter equivalent by aid of 28-degree palm oil medium fractionation substances (POMF)

A technology of palm oil and cocoa butter, which is applied in the field of preparation of cocoa butter, can solve the problems of reducing the quality of chocolate, changing the texture and taste of chocolate products, and achieves the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

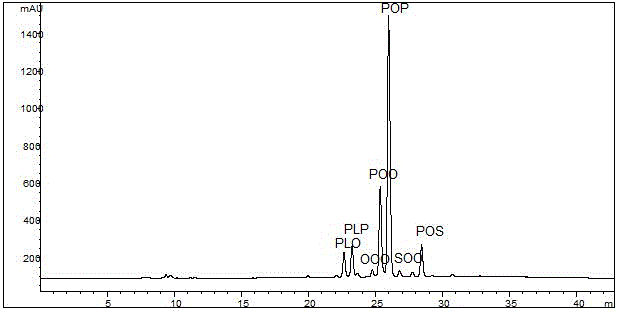

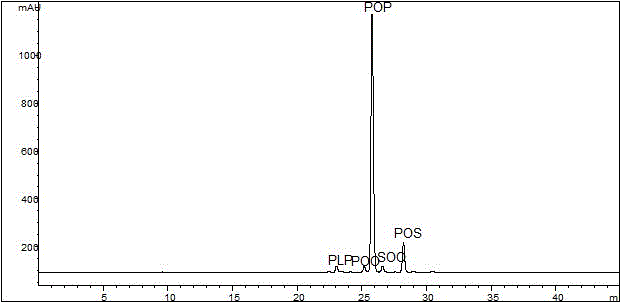

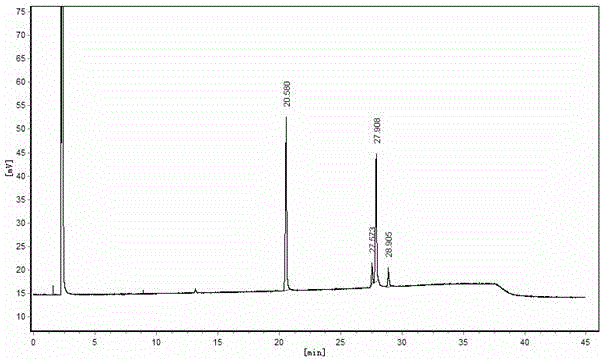

Image

Examples

Embodiment 1

[0022] A kind of method of utilizing 28 degree palm oil middle fraction (POMF) of the present invention to prepare cocoa butter-like, its concrete steps are:

[0023] (1). The 28 degree palm oil intermediate fraction (POMF) that takes 500g is mixed with the acetone of 2.2L, obtains mixed solution;

[0024] (2). The mixed solution in the above step (1) was warmed up to 40°C, left to stand for 50 minutes, and the 28-degree palm oil intermediate fraction (POMF) was completely dissolved in acetone to obtain a clear and transparent mixed solution;

[0025] (3). The clear and transparent mixed solution in the above step (2) is slowly cooled to 9.0° C. for crystallization, and left to stand for 11.5 hours to obtain a crystallized solution;

[0026] (4). The solution after crystallization in the above-mentioned step (3) is vacuum filtered, separated into solid fat and liquid fat, and the solid fat containing acetone is collected;

[0027] (5). Carry out vacuum distillation to the sol...

Embodiment 2

[0029] (1). The 28 degree palm oil middle fraction (POMF) that takes 5kg is mixed with the acetone of 25L, obtains mixed solution;

[0030] (2). The mixed solution in the above step (1) was warmed up to 40°C, left to stand for 50 minutes, and the 28-degree palm oil intermediate fraction (POMF) was completely dissolved in acetone to obtain a clear and transparent mixed solution;

[0031] (3). The clear and transparent mixed solution in the above step (2) is slowly cooled to 8.5° C. for crystallization, and left to stand for 12.5 hours to obtain a crystallized solution;

[0032] (4). The solution after crystallization in the above-mentioned steps (3) is vacuum filtered, separated into solid fat and liquid fat, and the solid fat containing a small amount of acetone is collected;

[0033] (5). The solid fat collected in the above step (4) is subjected to vacuum distillation to remove acetone to obtain cocoa butter-like (CBE).

Embodiment 3

[0035] (1). The 28 degree palm oil middle fraction (POMF) that takes 50kg mixes with the acetone of 250L, obtains mixed solution;

[0036] (2). The mixed solution in the above step (1) was warmed up to 40°C, allowed to stand for 55 minutes, and the 28-degree palm oil intermediate fraction (POMF) was completely dissolved in acetone to obtain a clear and transparent mixed solution;

[0037] (3). The clear and transparent mixed solution in the above step (2) is slowly cooled to 8.0° C. for crystallization, and left to stand for 13.2 hours to obtain a crystallized solution;

[0038] (4). The solution after crystallization in the above-mentioned steps (3) is vacuum filtered, separated into solid fat and liquid fat, and the solid fat containing a small amount of acetone is collected;

[0039] (5). The solid fat collected in the above step (4) is subjected to vacuum distillation to remove acetone to obtain cocoa butter-like (CBE).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com