Pixel array and manufacturing method of display device comprising the pixel array

A technology for pixel arrays and display devices, which is applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of small aperture size of masks, reduced product yield, increased process costs, etc. Process difficulty, reducing process cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

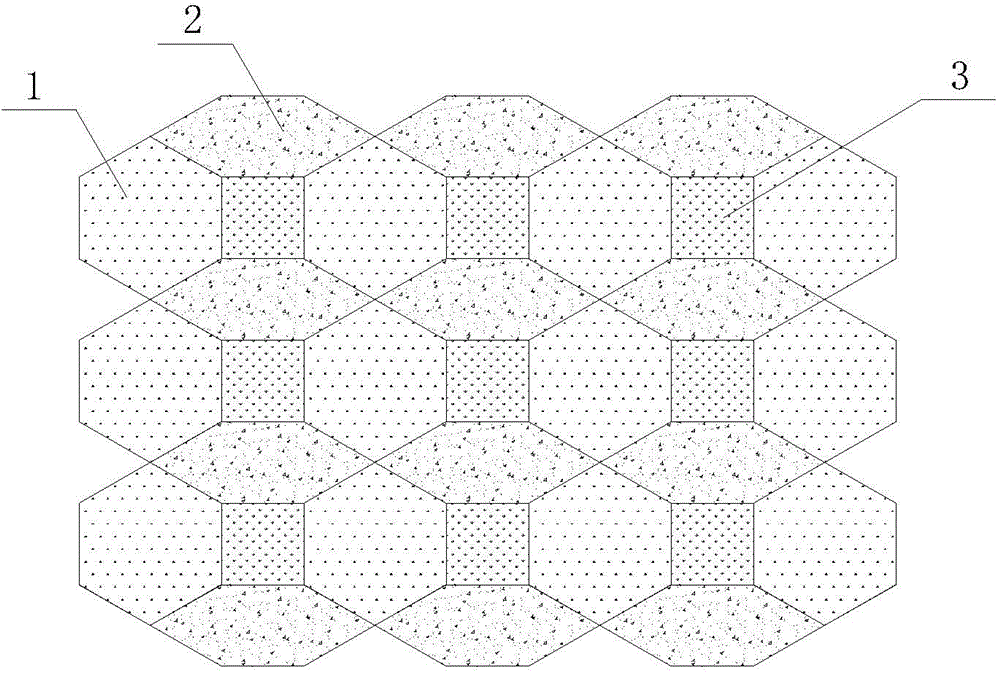

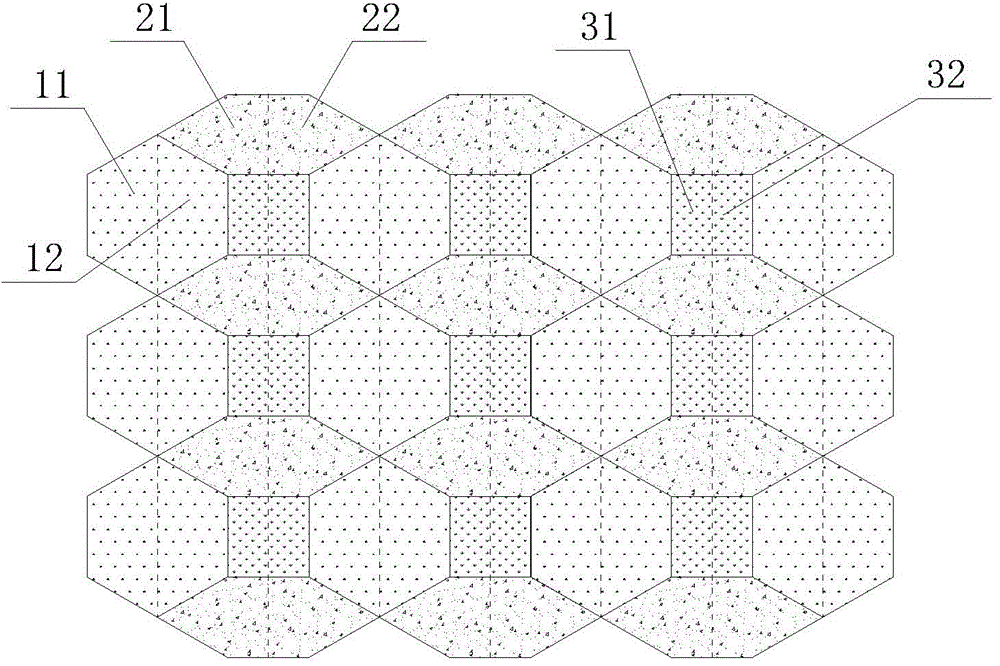

[0060] image 3 It is a schematic structural diagram of the pixel array in Embodiment 1 of the present invention; based on the above Figure 1~2 On the basis of the structure shown, in the first embodiment, each pixel unit includes two identical (identical in shape, length, area, material, etc.) sub-pixels, that is, the first pixel unit 1 includes the first For the sub-pixels 11 and 12 , the second sub-pixel unit 2 includes the second sub-pixels 21 and 22 , and the third sub-pixel unit 3 includes the third sub-pixels 31 and 32 .

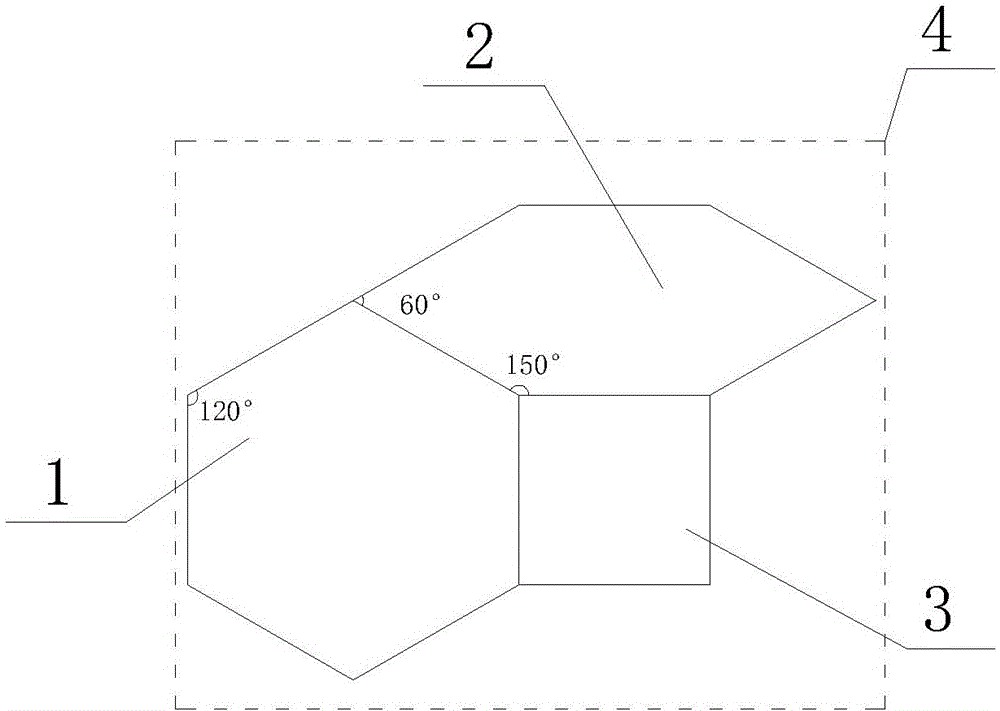

[0061] Figure 4 for image 3 Schematic diagram of the structure of a pixel unit in the image 3 In order to display clearly, the filling color in each pixel unit graph is also removed, that is, the same icon indicates the same device structure; as Figure 4 As shown, in the above-mentioned third pixel unit 3, on the midpoint of the side adjacent to the second pixel unit, a third median line perpendicular to the side is set (ie Figure 4 shown i...

Embodiment 2

[0063] Figure 5 It is a schematic structural diagram of the pixel array in Embodiment 2 of the present invention; Image 6 for Figure 5 Schematic diagram of the structure of a pixel unit in the Image 6 In order to display clearly, the filling color in each pixel unit graph is also removed, that is, the same icon indicates the same device structure; as Figure 5-6 shown, based on the above Figure 1~4 On the basis of the structure shown and the relevant descriptions of Embodiment 1, in Embodiment 2, like Embodiment 1, each pixel unit also includes two identical (shape, length, area, material, etc.) ) sub-pixels, correspondingly the resolutions of the display devices formed by them are the same, that is, different pixel array structures are used to form the display devices with the same resolution.

[0064] Further, such as Image 6 As shown, compared with Embodiment 1 in Embodiment 2, in the second sub-pixel unit 2, diagonals with an angle of 60° are connected to form a...

Embodiment 3

[0066] Figure 7 It is a schematic structural diagram of the pixel array in Embodiment 3 of the present invention; Figure 8 for Figure 7 Schematic diagram of the structure of a pixel unit in the Figure 8 In order to display clearly, the filling color in each pixel unit graph is also removed, that is, the same icon indicates the same device structure; as Figure 7-8 shown, based on the above Figure 1~6 On the basis of the structure shown, the relevant descriptions of Embodiment 1 and Embodiment 2, each sub-pixel unit is divided into four sub-pixels, so that each sub-pixel can form a pixel that emits white light with sub-pixels of other light-emitting colors; Specifically, in the third embodiment, each pixel unit is composed of four sub-pixels, that is, the first sub-pixel unit includes the first sub-pixels 11, 12, 13, 14, and the second sub-pixel unit includes the second sub-pixel 21 , 22, 23, 24, the third sub-pixel unit includes third sub-pixels 31, 32, 33, 34.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com