Formation method of semiconductor structure

A technology of semiconductor and plasma, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of semiconductor technology process node shrinkage, the inability to ensure that the structure size formed by etching meets the process requirements, etc., and achieve stable performance, The effect of precise structural dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, with the reduction of process nodes, the enhanced patterned mask cannot meet the manufacturing process requirements of small-scale structures.

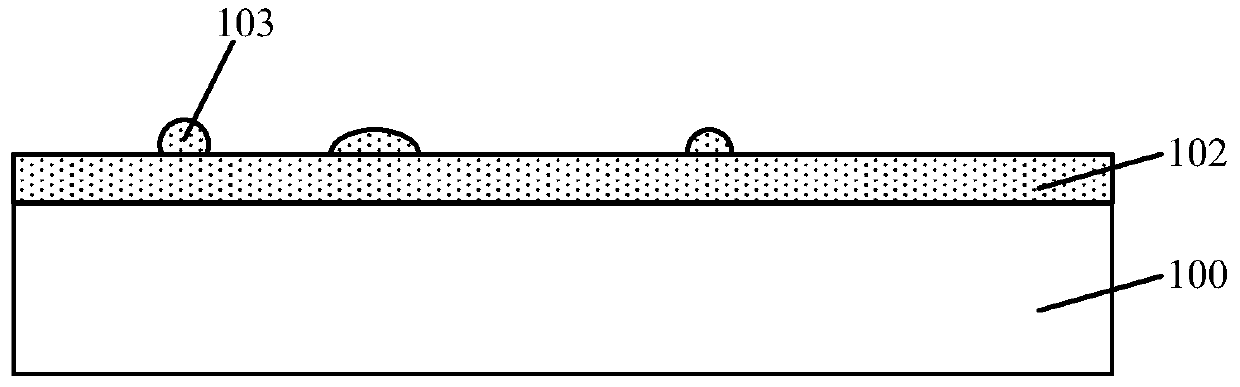

[0034] After research, please refer to figure 1 , figure 1 It is a schematic cross-sectional structure diagram of an embodiment of a semiconductor structure, including: a substrate to be processed 100; an enhanced patterning mask 102 located on the surface of the substrate to be processed 100. The material of the enhanced patterning mask 102 is amorphous carbon (amorphous carbon), and the formation process is plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD for short). However, since microspheres 103 are likely to be formed on the surface of the formed enhanced patterned mask 102, the microspheres 103 will cause the structural size of the enhanced patterned mask 102 to be inaccurate, and then easily cause the substrate 100 to be processed to be etch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com