Star block copolymer and preparation method thereof

A technology of block copolymers and compounds, applied in the field of star-shaped block copolymers, can solve the problems of high cost, poor heat resistance, weather resistance and aging resistance, complicated processes, etc., so as to improve the block efficiency, The effect of reducing the generation of styrene homopolymers and di- or high-copolymers, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] According to the first aspect of the present invention, the present invention provides a kind of preparation method of radial block copolymer, and this method comprises the following steps:

[0026] (1) In the presence of a diluent, the isomonoolefin is contacted with the initiator system to carry out a cationic polymerization reaction to obtain a polymerization system containing a polyisomonoolefin with reactive terminals;

[0027] (2) When the conversion rate of the isomonoolefin reaches more than 60%, the polymerization system is mixed with a solution containing styrene to carry out cationic polymerization;

[0028] Wherein, the initiator system contains at least one compound capable of providing carbocations, titanium tetrachloride and at least one activator,

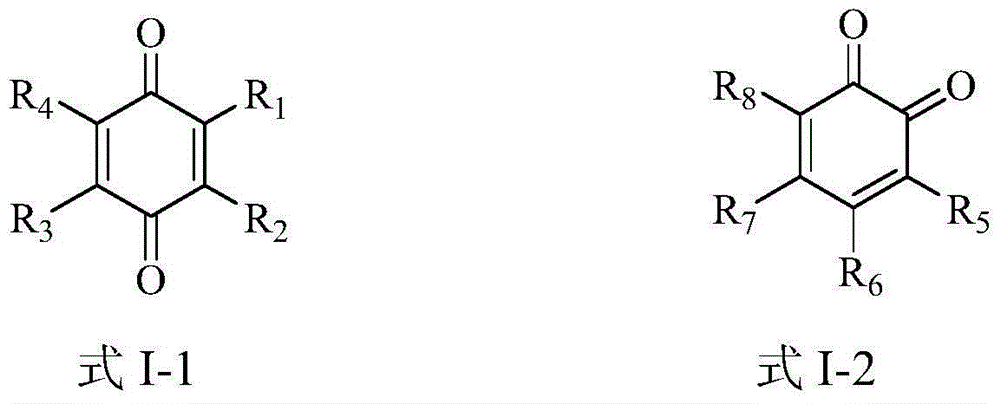

[0029] The activator is selected from compounds shown in formula I-1 and compounds shown in formula I-2,

[0030]

[0031] In formula I-1 and formula I-2, R 1 ~R 8 each independently -H, -X 1 , -NO 2 ...

Embodiment 1

[0078](1) Configuration of the initiator solution: First, add 0.246 g of tetrachloro-p-benzoquinone, 0.147 g of tricumyl chloride and 5 mL of dichloromethane into a 10 mL volumetric flask, dissolve and place in a cold bath at -80°C for later use.

[0079] Add 175mL of n-hexane, 175mL of dichloromethane and 30mL of isobutylene into a 1000mL three-necked flask under the protection of nitrogen, place the three-necked flask in a cold bath at -80°C, stir for 20 minutes, add the initiator solution prepared above, and continue stirring After 30 minutes, 1.8 mL of titanium tetrachloride was added for polymerization. After 40 minutes of reaction, 20 mL of isobutene was added to continue the reaction for 20 minutes, and a 1.2 g polyisobutene sample was taken to terminate.

[0080] (2) Add 100mL of styrene solution (which contains 12mL styrene, 44mL n-hexane and 44mL methylene chloride) pre-refrigerated at -80°C to the flask of step (1) and continue the reaction for 30 minutes. After the...

Embodiment 2

[0087] (1) Configuration of initiator solution: first add 0.341 grams of 2,3-dichloro-5,6-dicyano-p-benzoquinone, 0.147 grams of tricumyl chloride and 5 mL of dichloromethane into a 10 mL volumetric flask, after dissolving Store in a cold bath at -80°C for later use.

[0088] Add 175mL of n-hexane, 175mL of dichloromethane and 30mL of isobutylene into a 1000mL three-necked flask under the protection of nitrogen, place the three-necked flask in a cold bath at -80°C, stir for 20 minutes, add the initiator solution prepared above, and continue stirring After 20 minutes, 1.8 mL of titanium tetrachloride was added for polymerization. After 40 minutes of reaction, 20 mL of isobutene was added to continue the reaction for 20 minutes, and a 1.2 g polyisobutene sample was taken to terminate.

[0089] (2) Cationic polymerization was carried out in the same manner as in step (2) of Example 1.

[0090] Pour the polymer solution obtained after termination into a beaker and inject an equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com