Heat energy sustainable utilization and coal fire control system and method for coal field fire zone

A fire area and coal field technology, applied in the field of sustainable utilization of thermal energy in coal field fire area and coal fire control system, can solve the problems of resource waste, ecological environment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An example of the present invention will be further described below in conjunction with accompanying drawing:

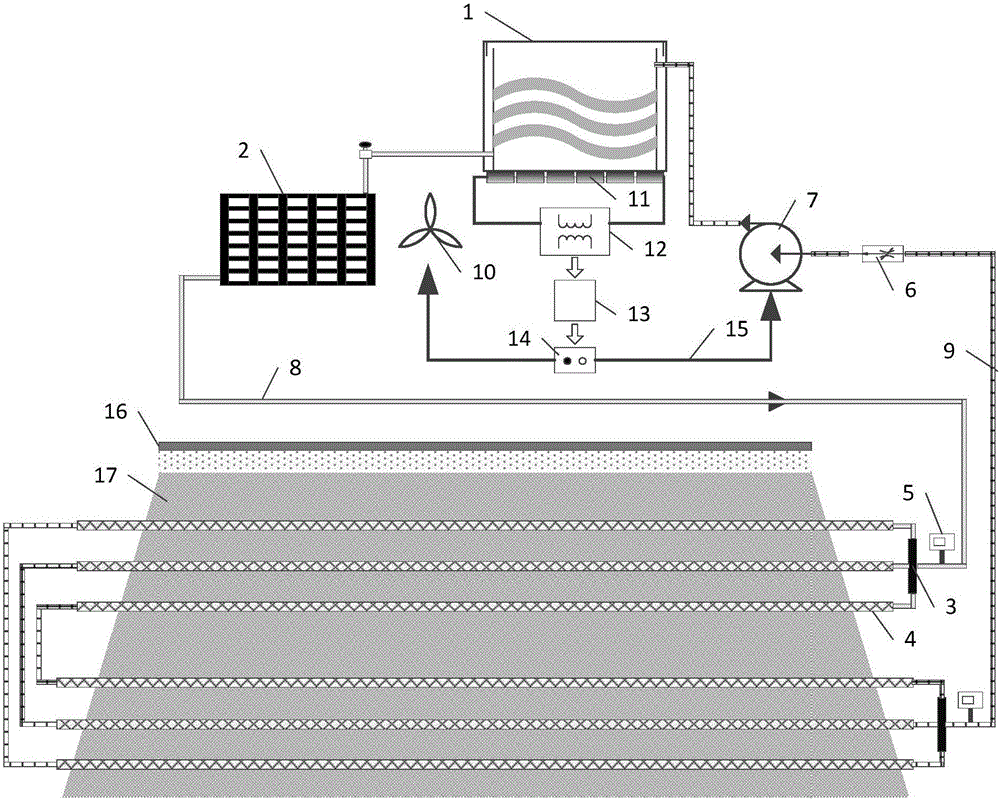

[0012] The thermal energy sustainable utilization system in the coal field fire area consists of a vacuum liquid storage tank 1, a radiator 2, a horizontal drilling 4, a high temperature resistant circulation pump 7, a thermoelectric power generation module 11, a voltage stabilizing and boosting module 12, a storage battery pack 13 and an inverter 14 and so on.

[0013] Use machine excavation means to isolate the coalfield fire area 17, arrange horizontal boreholes 4 in the independent coalfield fire area 17, inject normal temperature heat carrier into multiple groups of horizontal boreholes 4 through the heat dissipation pipeline 8 and the multi-way valve 3 on the ground surface 16, During the process, the heat carrier absorbs the heat of the coalfield fire area 17 to form a high-temperature heat carrier, which is sent by the high-temperature-resistant circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com