Two-dimensional nitrogen-doped hierarchical pore carbon nano-sheet as well as preparation method and application thereof to lithium/sulfur battery

A technology of hierarchical porous carbon and carbon nanosheets, applied in the field of electrochemistry, can solve problems such as energy consumption, unfavorable large-scale production, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

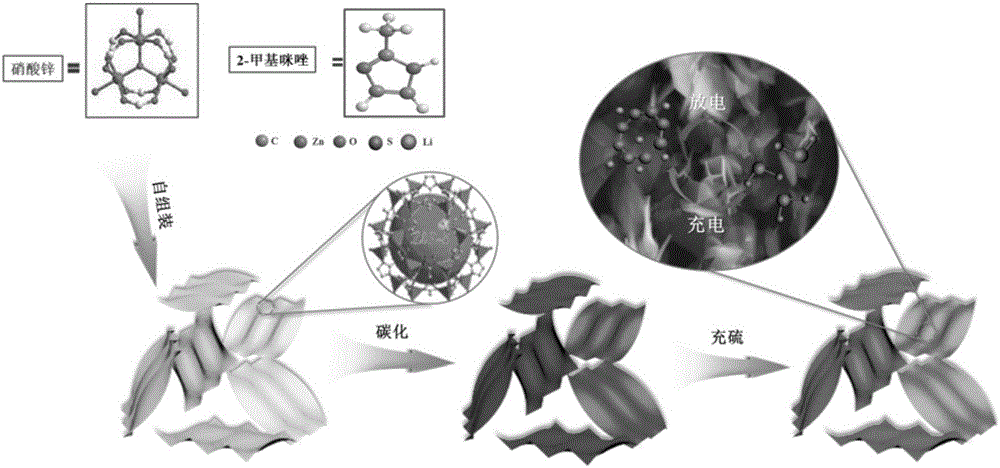

[0083] The schematic diagram of the preparation process of the two-dimensional nitrogen-doped hierarchically porous carbon nanosheets in Example 1 can be found in figure 1 .

[0084] (1) Take by weighing 0.330g zinc nitrate and dissolve in 90mL water to obtain solution A (concentration of zinc nitrate in solution A is 0.019M), 0.985g 2-methylimidazole is dissolved in 90mL methanol to obtain solution B (2- The concentration of methylimidazole is 0.133M), the solution B is quickly poured into the solution A, stirred for 24h, centrifuged, washed, and dried to obtain a white solid powder, that is, a zinc metal organic framework;

[0085] (2) Transfer the white solid powder into a tube furnace, heat at 1°C min -1 The heating rate is increased to 920°C, the temperature is maintained for 2h, and then at 1°C min -1 The cooling rate is reduced to room temperature, and the finished two-dimensional nitrogen-doped hierarchical porous carbon nanosheets are obtained.

[0086] Using the s...

Embodiment 2

[0089] (1) is identical with the step (1) of embodiment 1;

[0090] (2) same as the step (1) of embodiment 1;

[0091](3) Activate the two-dimensional nitrogen-doped hierarchical porous carbon nanosheets prepared in step (2). Specifically, weigh 1 g of the two-dimensional nitrogen-doped hierarchical porous carbon nanosheets prepared in Example 1 and mix them with 4 g of KOH. Mix and place in a nickel tube furnace at 10°C min -1 The heating rate is increased to 700°C, kept at a constant temperature for 2 hours, and then at 2°C min -1 The cooling rate was lowered to room temperature, and the obtained product was placed in 10wt% HCl again, and after standing for 24 hours, it was washed and dried to obtain activated two-dimensional nitrogen-doped hierarchically porous carbon nanosheets.

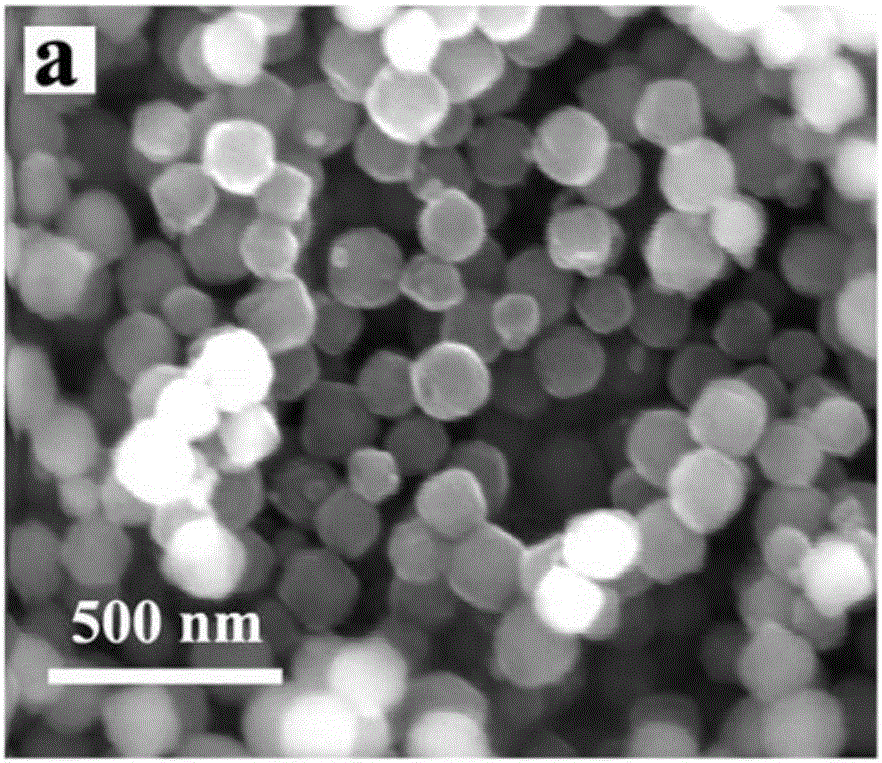

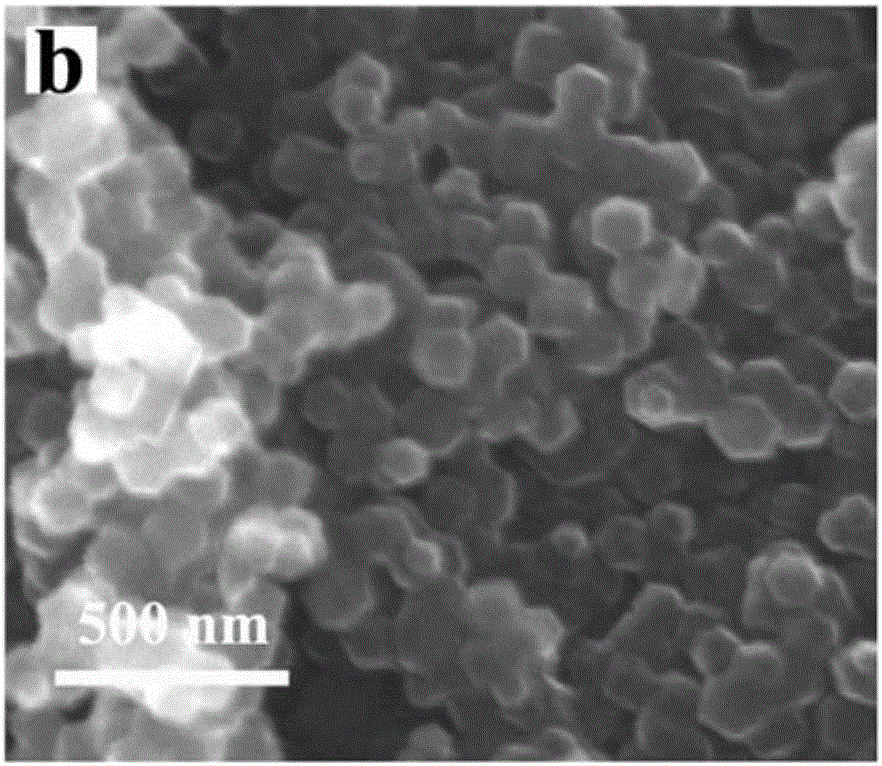

[0092] Figure 2c and Figure 2d They are the SEM images of the zinc metal-organic framework obtained in step (1) of Example 2 and the activated two-dimensional nitrogen-doped hierarchical ho...

Embodiment 3

[0096] (1) Dissolve 0.330g of zinc nitrate in 90mL of water to obtain solution A, dissolve 0.985g of 2-methylimidazole in 90mL of methanol to obtain solution B, quickly pour solution B into solution A, stir for 24h, centrifuge, wash, Dried to obtain a white solid powder;

[0097] (2) Transfer the white solid powder into a tube furnace, heat at 1°C min -1 The heating rate is increased to 1100°C, kept at constant temperature for 2 hours, and then at 1°C min -1 The cooling rate is reduced to room temperature, and the finished two-dimensional nitrogen-doped hierarchical porous carbon nanosheets are obtained.

[0098] (3) Activating the two-dimensional nitrogen-doped hierarchically porous carbon material obtained in step (2), the method and conditions of activation are the same as those in step (3) of Example 2;

[0099] Using the sample two-dimensional nitrogen-doped hierarchical porous carbon nanosheet in Example 3 as the positive electrode to make a battery, and tested it, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com