Colored photosensitive resin composition and color filter produced therefrom

A technology of photosensitive resin and composition, applied in optical filter, photosensitive material for opto-mechanical equipment, optics, etc., can solve problems such as use limitation, and achieve the effect of excellent adhesion and high development rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034]

[0035] The colored photosensitive resin composition of the present invention contains an alkali-soluble resin (A). Of course, the composition of the present invention may also contain a colorant (B), a photopolymerizable compound (C), a photopolymerization initiator (D) and a solvent (E), which are generally used in the related art for coloring photosensitive resin combinations. thing. In addition, any additional components generally used in the related field, such as additives, may also be contained.

[0036]

[0037] The alkali-soluble resin of the present invention has reactivity to light or heat and alkali solubility, and serves as a dispersion solvent for the respective components in the composition of the present invention.

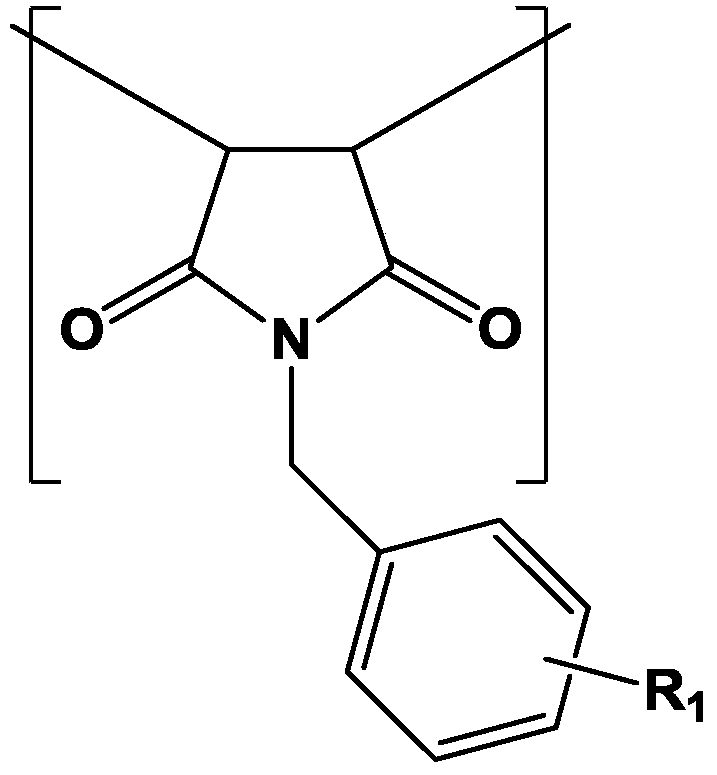

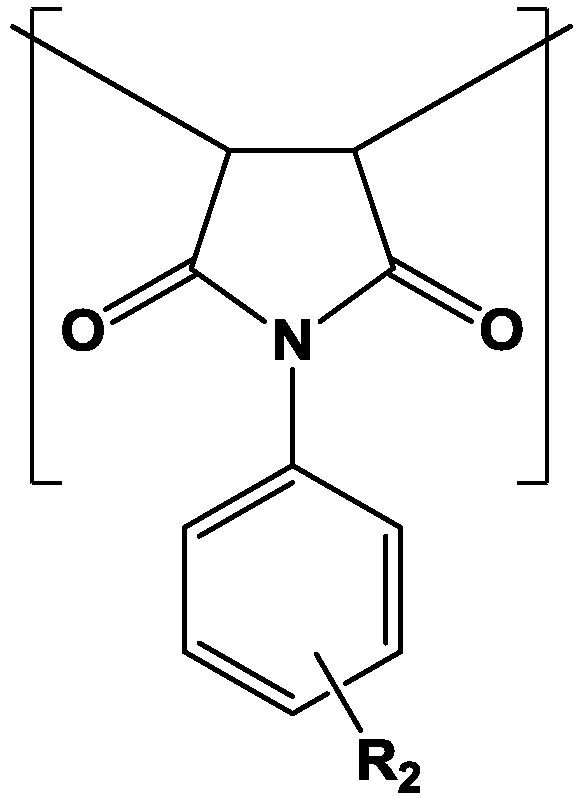

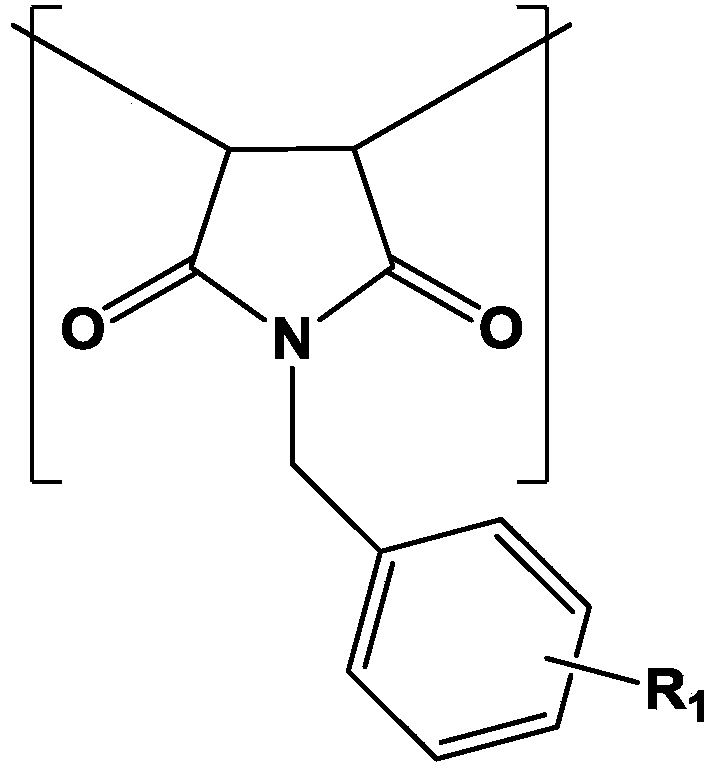

[0038] The colored photosensitive resin composition of the present invention contains an alkali-soluble resin containing maleimide-based repeating units. The alkali-soluble resin has a glass transition temperature of 100 to 200°C. ...

Synthetic example 1

[0179]

[0180] 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, 2 parts by weight of Azobisisobutyronitrile, 13.0 parts by weight of acrylic acid, 45.0 parts by weight of N-benzylmaleimide, 15 parts by weight of phenylmaleimide, 27 parts by weight of methyl methacrylate and 3 parts by weight of n-dodecyl mercapto, and the air in the flask was exchanged with nitrogen. Then, a reaction was performed for 8 hours while the temperature was raised to 80° C. and stirred.

[0181] The synthesized alkali-soluble resin had an acid value of 101.5 mg KOH / g (solid content), and a weight average molecular weight of 12350 as measured by gel permeation chromatography (GPC) based on polystyrene.

Synthetic example 2

[0182]

[0183] The synthesis of alkali-soluble resin is synthesized according to the same procedure as described in Synthesis Example 1, just using 10.0 parts by weight of acrylic acid, 30.0 parts by weight of N-benzylmaleimide, 30 parts by weight of phenylmaleimide and 30 parts by weight of methyl methacrylate instead of 13.0 parts by weight of acrylic acid, 45.0 parts by weight of N-benzylmaleimide, 15 parts by weight of phenylmaleimide and 27 parts by weight of methacrylic acid methyl ester.

[0184] The synthesized alkali-soluble resin had an acid value of 78.9 mg KOH / g (solid content), and a weight average molecular weight of 13800 as measured by GPC in terms of polystyrene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com