Printing lithographic plate making process

A process, lithographic technology, applied in the field of printing lithographic platemaking process, can solve the problems of low development efficiency, infiltration of developer solution, etc., and achieve the effects of uniform distribution of developer solution, reduction of residues, and improvement of development speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

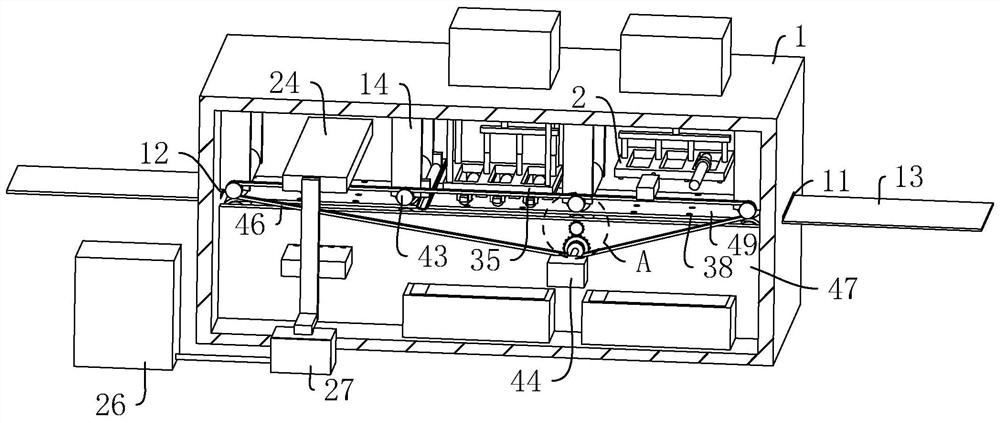

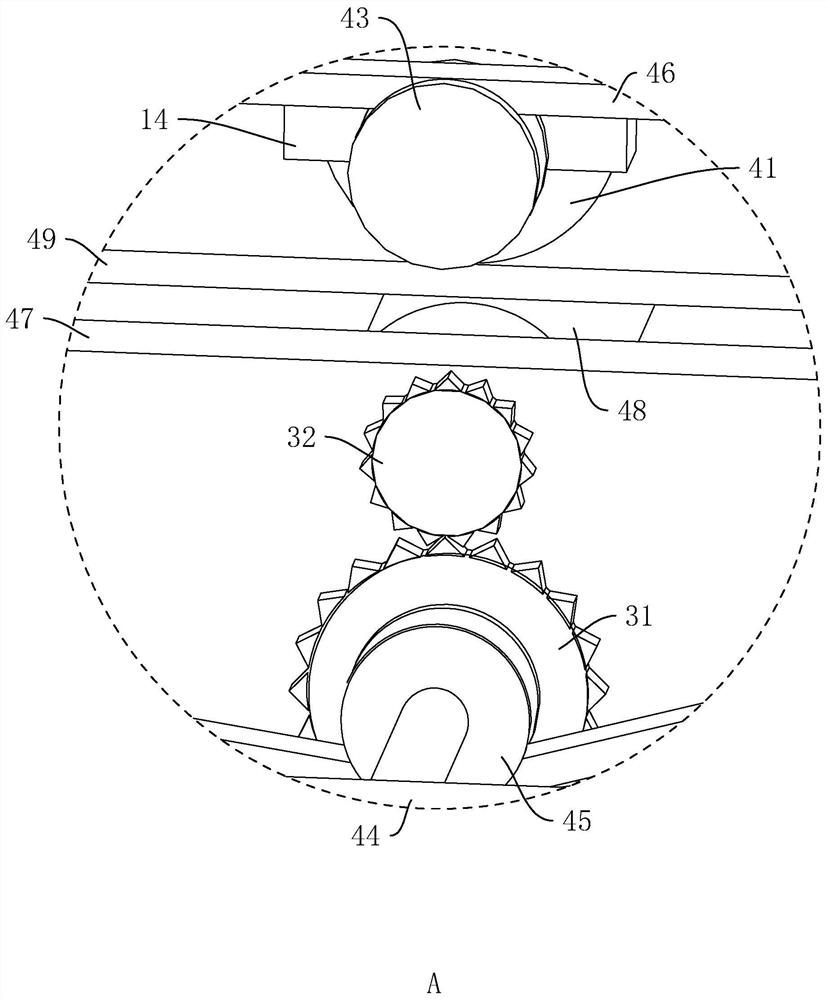

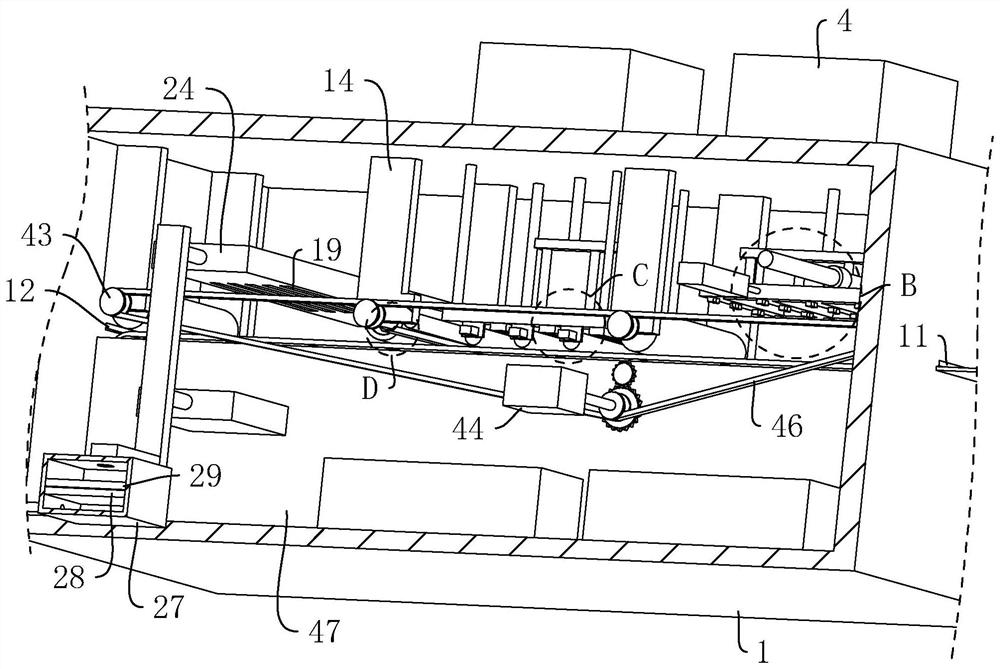

[0044] The application will be described in further detail below in conjunction with the accompanying drawings.

[0045] The embodiment of the present application discloses a printing lithography plate-making process, which specifically includes the following steps:

[0046] Step 1, exposure, using a printing machine to decompose the photosensitive agent in the blank part of the printing plate;

[0047] Step 2, developing, using a developing device to dissolve the photosensitive agent in the blank part of the printing plate by the developing solution;

[0048] Step 3, gluing, evenly coat a layer of protective glue on the surface of the printing plate, the protective glue can be gum arabic, and place the printing plate in a dark room to dry naturally;

[0049] Step 4. Inking. If the printing plate is not in use temporarily, the surface of the graphic part of the printing plate is coated with a layer of ink by rolling the ink roller. If printing is carried out immediately, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com