Scanning method adapted to scanning tunnel microscope

A scanning method and scanning tunnel technology, which are applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problem of increasing scanning time, and achieve the effect of improving imaging speed and ensuring measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

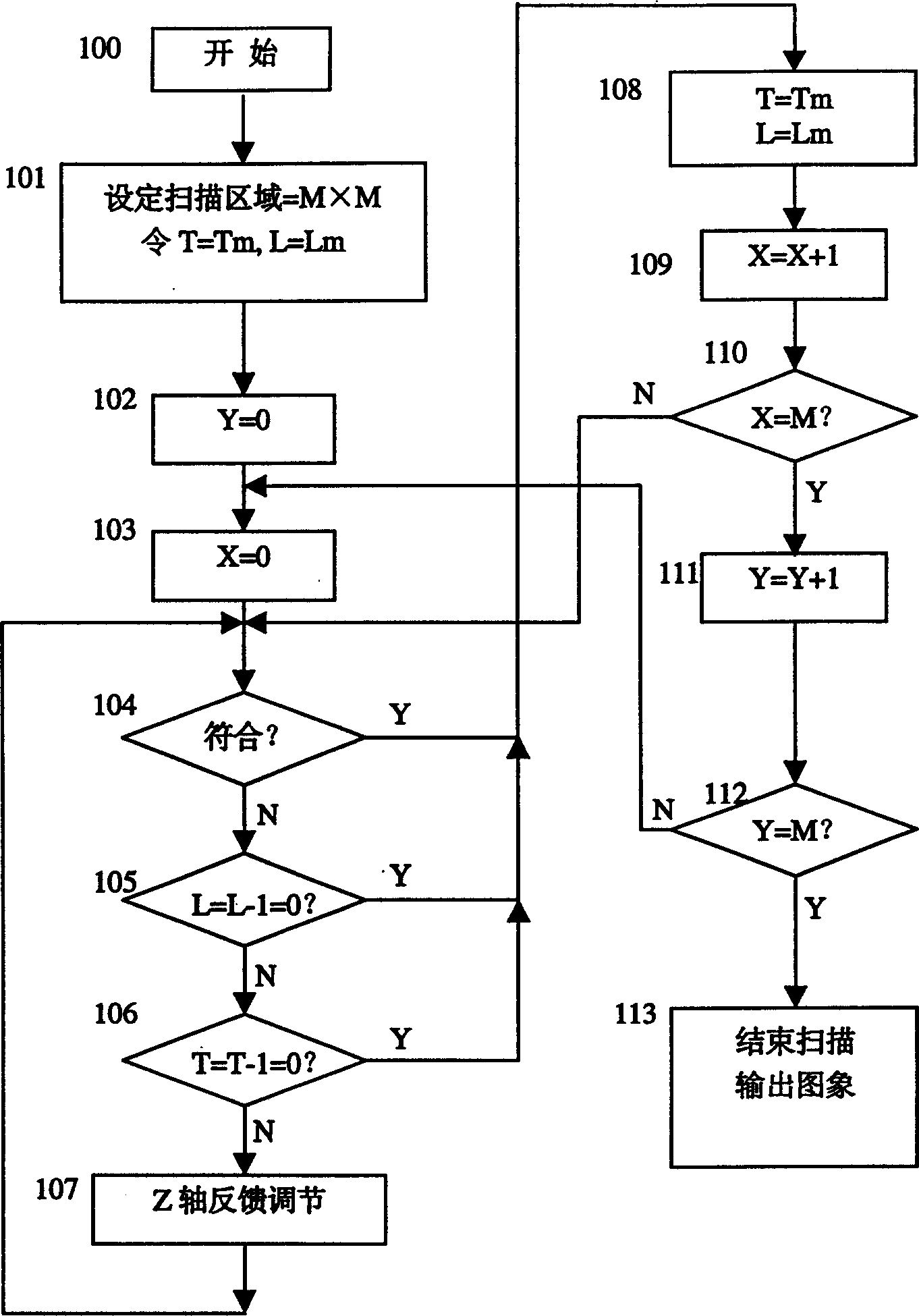

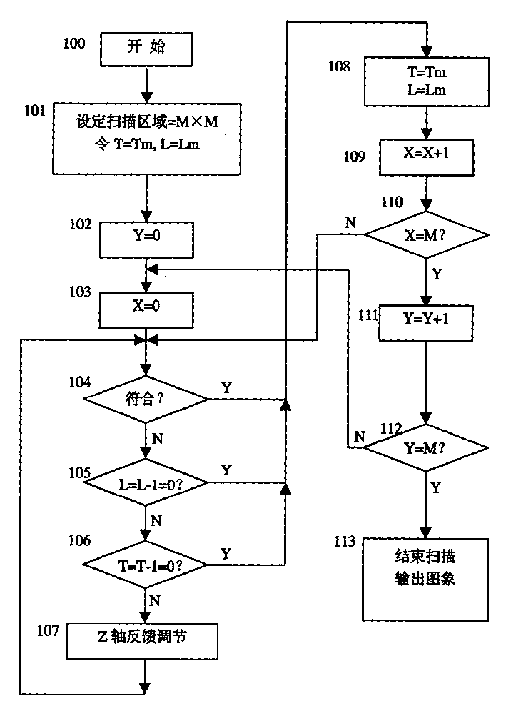

[0011] It is suitable for the scanning method of scanning tunneling microscope. The scanning motion of the X and Y scanners is controlled by the coincidence signal generated by the tunnel current detection and current setting value comparison circuit. The process is: the tunnel current is amplified to 0 by the amplifier of the probe The voltage of ~5V is converted into a digital signal by a 16-bit A / D converter and enters the computer; the computer performs a comparison operation according to the control program, and if it does not match, it continues to adjust the displacement; if it matches, the computer sends out a control signal , through the X direction, (if the X direction scans to the maximum point position, it is the Y direction), the 20-bit D / A converter converts it into a voltage signal of 0 ~ 10V, and sends it to the X direction (if the X direction scans to the maximum point position, then it is the Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com