branched fluorinated photopolymer

A photopolymer, polymer technology, application to photopolymer compositions having improved, researched or developed claims

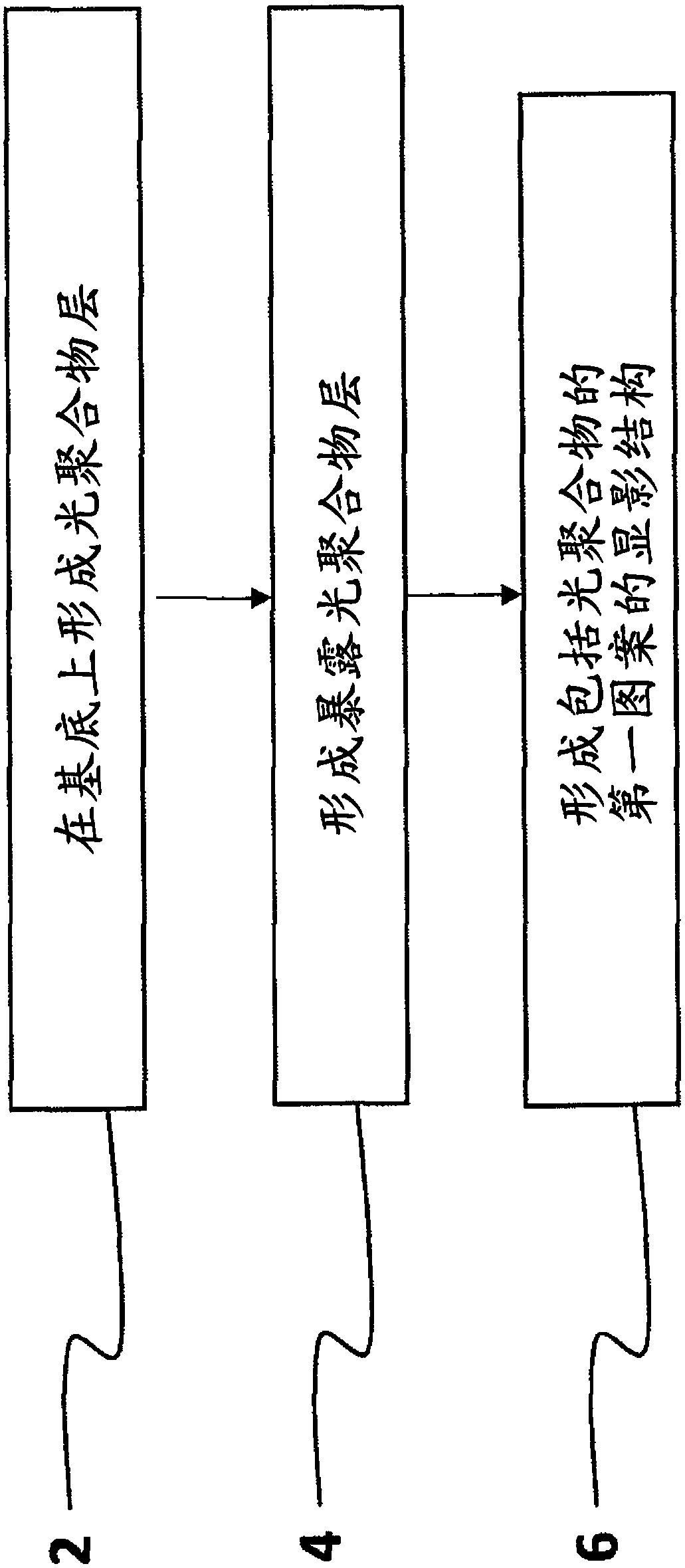

In the field of 0004, problems such as adoption can be solved, and the effects of improving contrast, improving stripping rate, and improving photosensitivity can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0097] Some non-limiting embodiments of the present disclosure include, but are not limited to the following.

[0098] 1. A fluorinated photopolymer composition comprising:

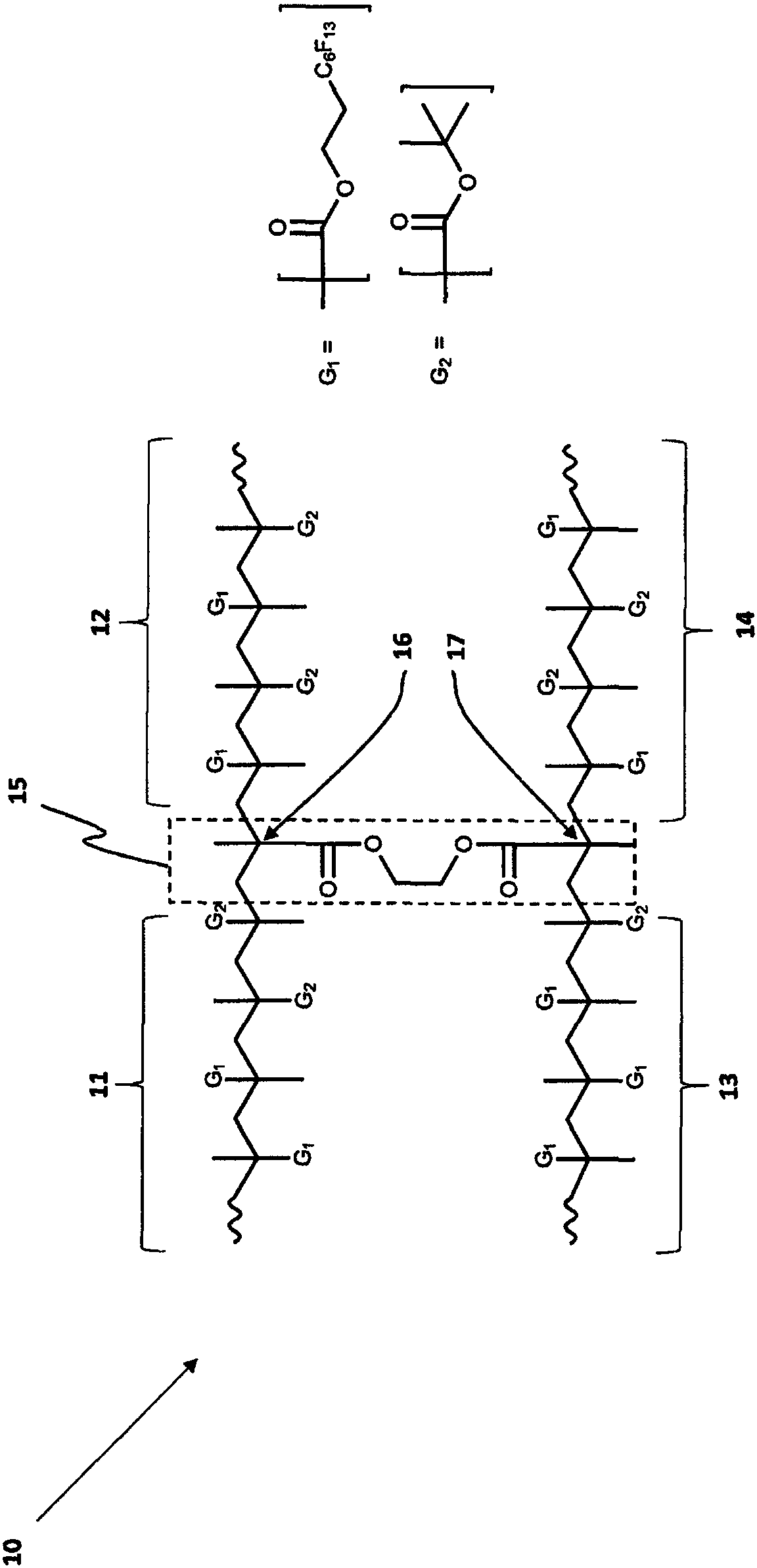

[0099] a branched copolymer comprising a branch unit, a first repeat unit having a fluorine-containing group, and a second repeat unit having a solubility-altering reactive group; and

[0100] Fluorinated solvents.

[0101] 2. The composition of embodiment 1, further comprising a sensitizing dye.

[0102] 3. The composition of embodiment 2, wherein the sensitizing dye is attached to the branched copolymer as an additional repeat unit.

[0103] 4. The composition of any one of embodiments 1 to 3, wherein the copolymer comprises chain-terminating sulfur- or bromine-containing groups.

[0104] 5. The composition of any one of embodiments 1 to 4, wherein the mole % of branching units relative to the total amount of all copolymer units ranges from 0.5% to 10%.

[0105] 6. The composition of any one of embo...

Embodiment

[0128] Comparative Composition 1

[0129] Copolymers without branch units are formed by the polymerization of 1H,1H,2H,2H-perfluorooctyl methacrylate (“FOMA”) as the first monomer with fluorine-containing groups, methyl Tert-butyl acrylate ("TBMA") as the second monomer with solubility-altering reactive groups and 9-anthrylmethyl methacrylate ("AMMA") as the monomer with the sensitizing dye. The relative ratios of the three monomers are 49.9 mol% / 48.0 mol% / 2.1 mol%, respectively, and the polymerization reaction is carried out in a hydrofluoroether solvent. The total amount of fluorine content of the copolymer was 42.5% by weight relative to the total weight of the copolymer. Comparative Composition 1 also contained 0.8% by weight (relative to the total weight of the copolymer) of PAG added to the solution. The following procedure can be used.

[0130] A clean, dry 1L four-neck jacketed reactor was equipped with a mechanical stirrer with Teflon blades, a reflux condenser wit...

Embodiment 2

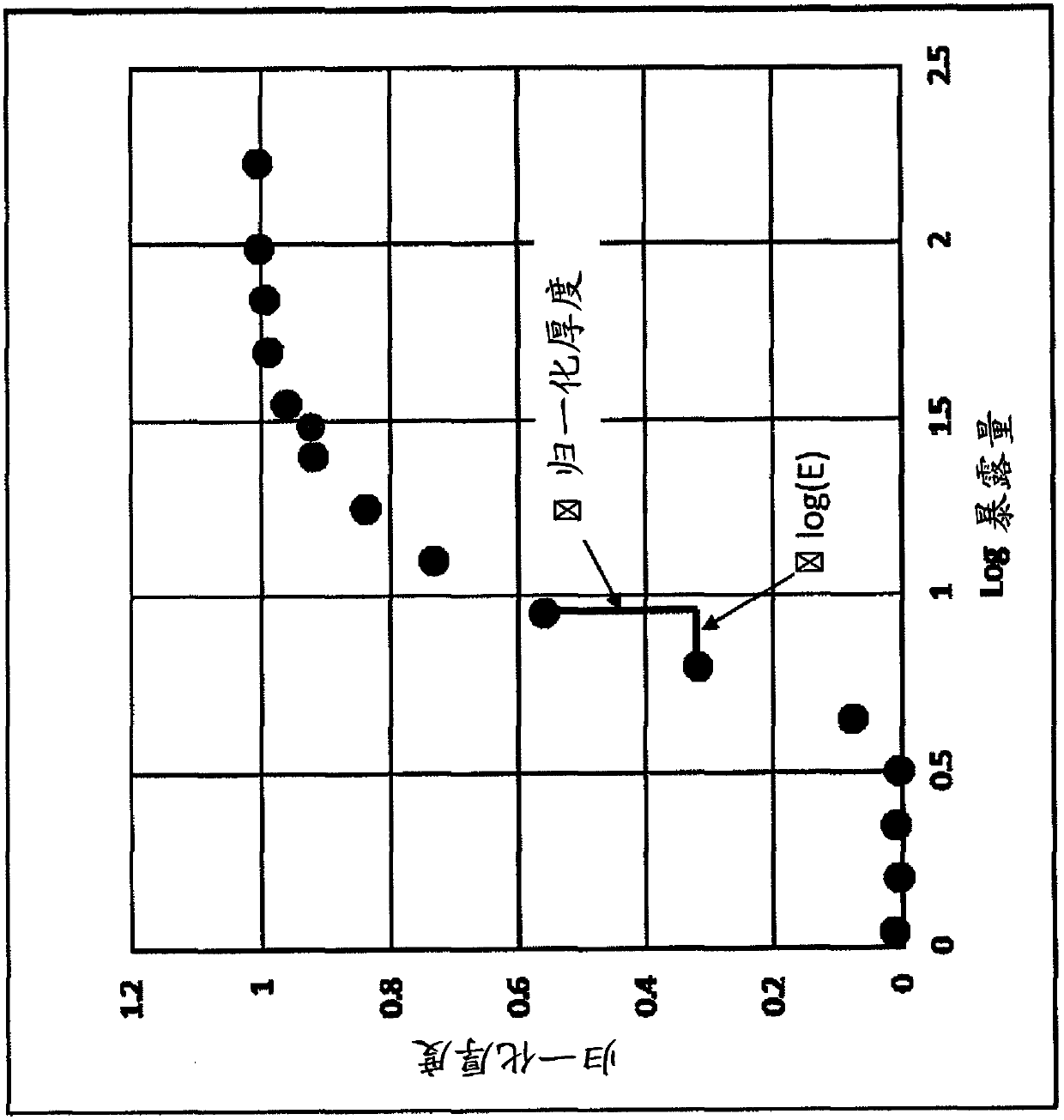

[0141] The branched fluorinated photopolymer was spin-coated onto a silicon wafer and then soft baked at 90°C for 60 seconds. The photopolymer layer is about 1.4 μm thick. The photopolymer solution contained HFE-6512 as coating solvent, CGI 1907 as PAG (0.8% by weight relative to polymer weight), and FOMA, TBMA in molar ratios of 27.3, 30.4, 37.3, 3 and 2, respectively , a branched fluorinated polymer of a copolymer of ECPMA, EGDMA (ethylene glycol dimethacrylate) and AMMA. The photopolymer has 28% by weight of fluorine relative to the weight of the polymer. Contrast curves were measured as described above using HFE-7200 as the developer. The process was then repeated for various mixtures of HFE-7200 and HFE-7600, and various parameters were determined, as reported in Table 2. Note that if the low exposure is completely removed and when E maxWhen the etch is less than 0.25, only the maximum contrast value is reported. In Table 2, the "Clear Time" item for pure HFE-7600 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com